A kind of lightning shock resistant composite insulator

A composite insulator, lightning impact technology, applied in insulators, suspension/strain insulators, circuits, etc., can solve the problems of catenary equipment damage, insulator flashover, breakdown, etc., to improve the level of lightning resistance, increase and service life, reduce The effect of the strength of the lightning impulse voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

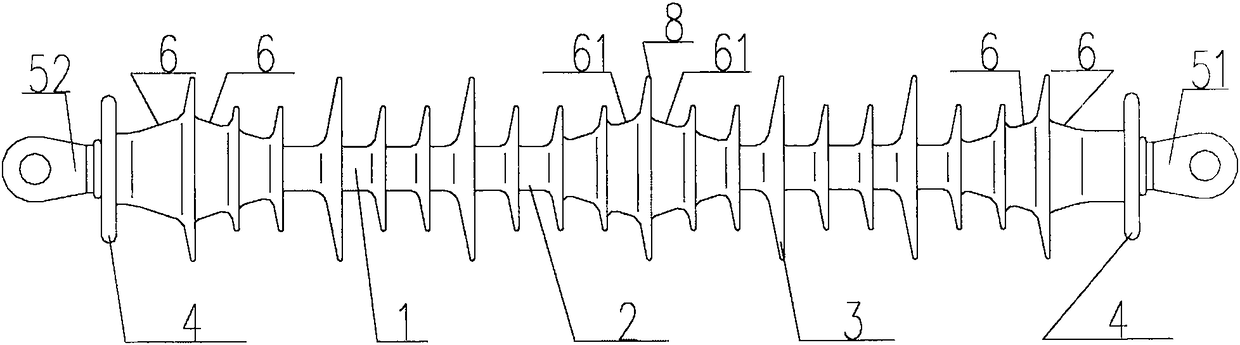

[0048] A lightning impact resistant composite insulator of the present invention comprises a mandrel 1, a first sheath 2, an umbrella shed 3, a voltage equalizing shielding ring 4, a high voltage end fitting 51, a grounding end fitting 52, a first stress cone 6 and a second sheath Set of 8. The first sheath 2 is located on the outer side of the mandrel 1; the shed 3 is arranged on the first sheath 2; the first stress cone 6 is provided with two groups, and each group is composed of two first stress cones 6 with the bottom of the cone bonded together. They are respectively arranged at both ends of the mandrel, the first stress cone is the external insulation stress cone; the voltage equalizing shield ring 4 is located between the stress cone 6 and the high voltage end fitting 51 and / or the grounding end fitting 52; the second sheath 8 is HTV silicone The sheath is arranged on the outside of the hardware.

specific Embodiment 2

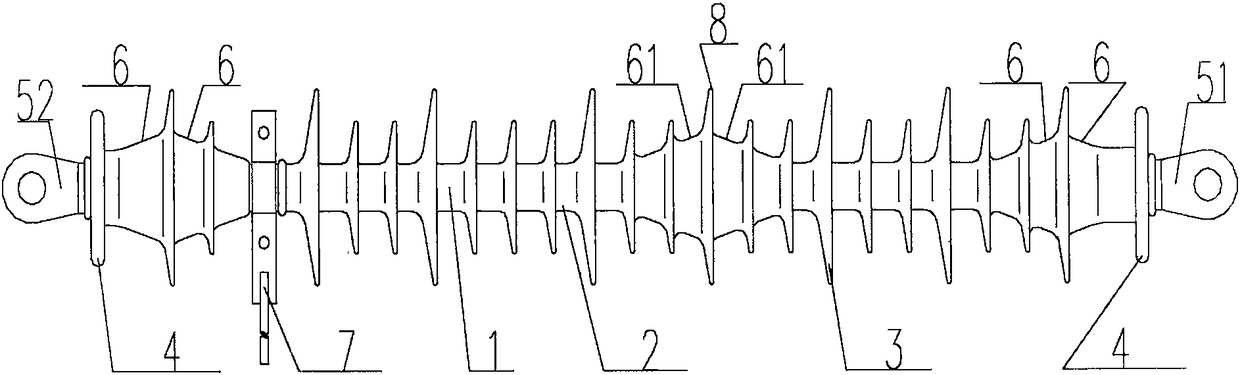

[0049] The present invention is a double-insulated lightning impact resistant composite insulator, comprising a mandrel 1, a first sheath 2, an umbrella skirt 3, a voltage equalizing shielding ring 4, a high-voltage end fitting 51, a grounding end fitting 52, a first stress cone 6 and a second stress cone. Second sheath 8. The first sheath 2 is located on the outer side of the mandrel 1; the shed 3 is arranged on the first sheath 2; the first stress cone 6 is provided with two groups, and each group is composed of two first stress cones 6 with the bottom of the cone bonded together. The first stress cone is the external insulation stress cone; the equalizing shielding ring 4 is located between the stress cone 6 and the high-voltage end fitting 51 and / or the grounding end fitting 52; the jumper clamp 7 is set on the On the bolt between the high-voltage end fitting 5 and the mandrel 1; the second sheath 8 is an HTV silicone sheath, which is located outside the fitting.

specific Embodiment 3

[0050] A lightning impact resistant composite insulator of the present invention comprises a mandrel 1, a first sheath 2, an umbrella skirt 3, a voltage equalizing shielding ring 4, a high voltage end fitting 51, a grounding end fitting 52, a first stress cone 6, a second stress Cone 61 and the second sheath 8. The first sheath 2 is located on the outer side of the mandrel 1; the shed 3 is arranged on the first sheath 2; the first stress cone 6 is provided with two groups, and each group is composed of two first stress cones 6 with the bottom of the cone bonded together. They are respectively arranged at both ends of the mandrel. There is at least one set of second stress cones 61. The second stress cones 61 are arranged on the mandrel. Each group is composed of two second stress cones with the bottoms of the cones attached together. The first Both the stress cone 6 and the second stress cone 61 are external insulation stress cones; the equalizing shielding ring 4 is located b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com