Pump-valve compound control hydraulic system for full-hydraulic straightener

A hydraulic system and composite control technology, which is applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of low transmission efficiency and low efficiency of the system, achieve fast response speed, low cost, The effect of increasing the degree of automation and control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

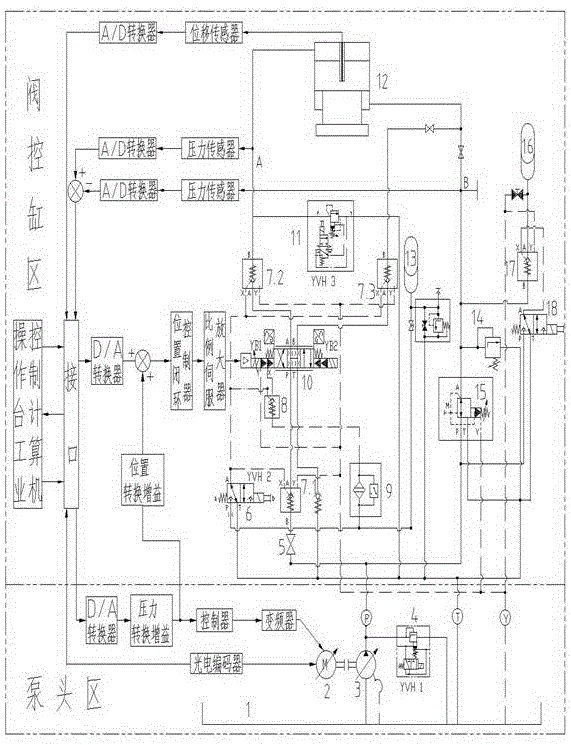

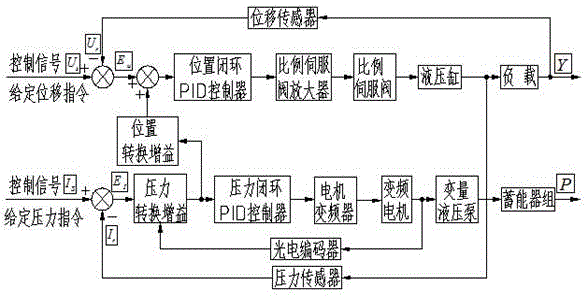

[0029] As shown in Figure (1): the variable frequency motor 2 forms a hydraulic power source through variable frequency speed regulation and the variable hydraulic pump 3. Since the hydraulic pumps all stipulate the minimum speed (n>200r / min), when the flow rate is controlled by this invention, when the flow rate When it is small, it is controlled by changing the displacement of the pump; when the flow rate is greater than the minimum value, it is controlled by changing the speed of the electric frequency motor, and when the pressure is controlled, it is controlled by changing the displacement of the pump. The straightening process is a process of heavy load, large flow, and high response. The dynamic response speed of the variable frequency motor is slow. In order to prevent the flow of the hydraulic pump from instantly failing to meet the response requirements of the system, an accumulator group 13 is connected to the outlet of the hydraulic pump. , as an energy storage eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com