Mortise and tenon connection assembled self-insulation and heat insulation hollow shear wall system and its hoisting method

A shear wall and prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of numerous construction procedures, complex construction process of thermal insulation layer, high cost, and avoid poor fire performance, low demand for hoisting equipment, and reduced costs. The effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

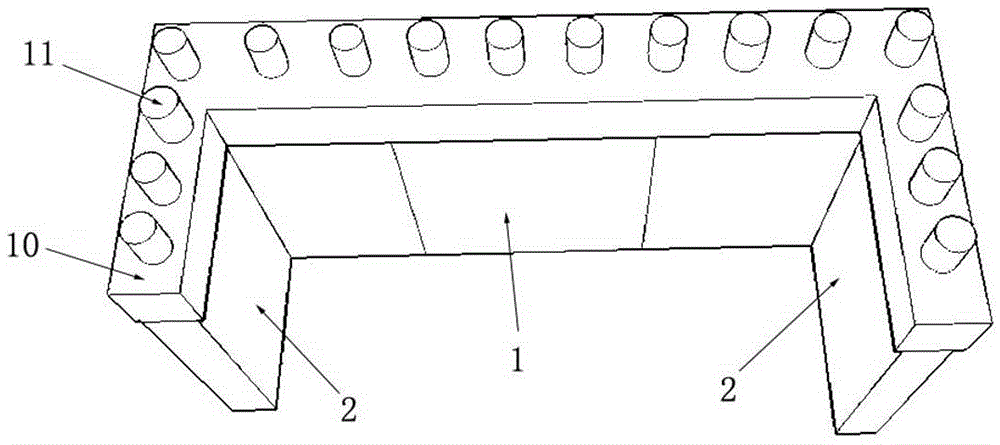

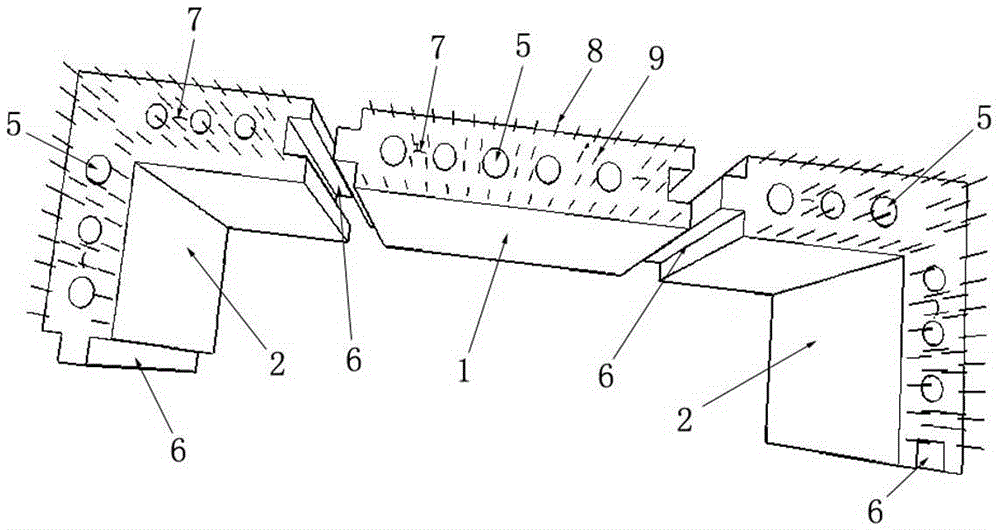

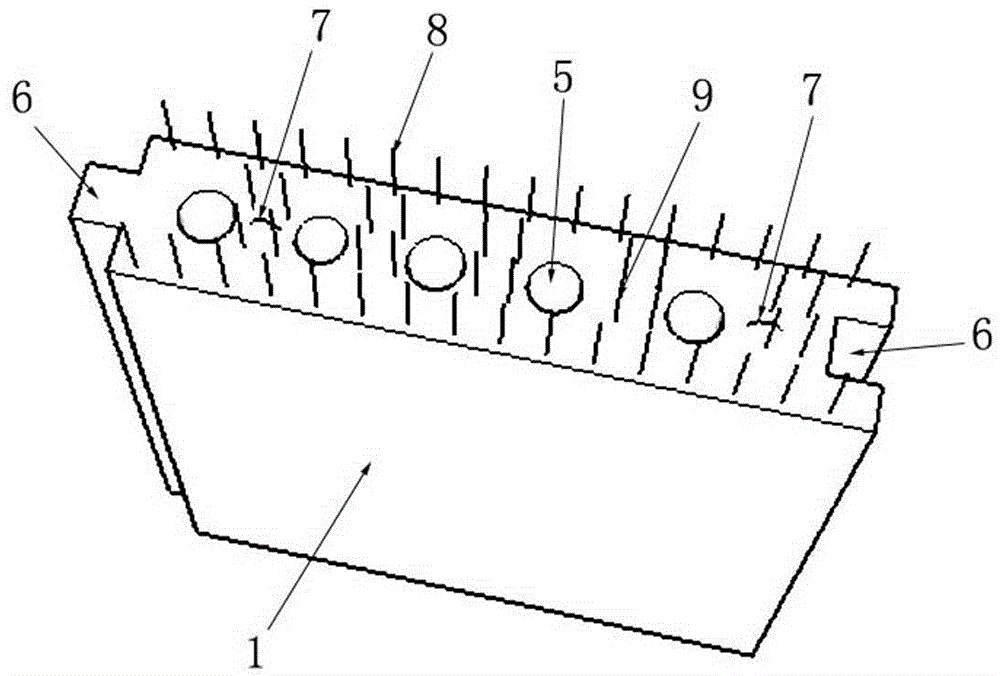

[0031] like Figure 1 to Figure 8As shown, a mortise and tenon joint assembled self-insulating hollow shear wall system includes an inline wall panel unit 1, an L-shaped wall panel unit 2, a T-shaped wall panel unit 3 and an end wall panel unit 4. Each wall panel unit is provided with a number of longitudinal hollow circular holes 5, and the side ends of the inline wall panel unit 1, the L-shaped wall panel unit 2 and the T-shaped wall panel unit 3 are all provided with sockets for interconnection. Mortise and tenon structure 6, one side of the end wall panel unit 4 is provided with a tenon and tenon structure 6 for mutual connection, and the connection parts of each tenon and tenon structure 6 are coated with epoxy resin concrete adhesive; The top edge of the wall panel unit is extended upward with a hoisting ring 7, an externally extended anchoring steel bar 8 and an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com