Small box girder bridge and building method thereof

A small box girder and bridge technology, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve problems such as time-consuming, achieve high continuity, improve use efficiency, and improve construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 provided by the present invention is an embodiment of a kind of small box girder bridge provided by the present invention, in the embodiment of a kind of small box girder bridge provided by the present invention:

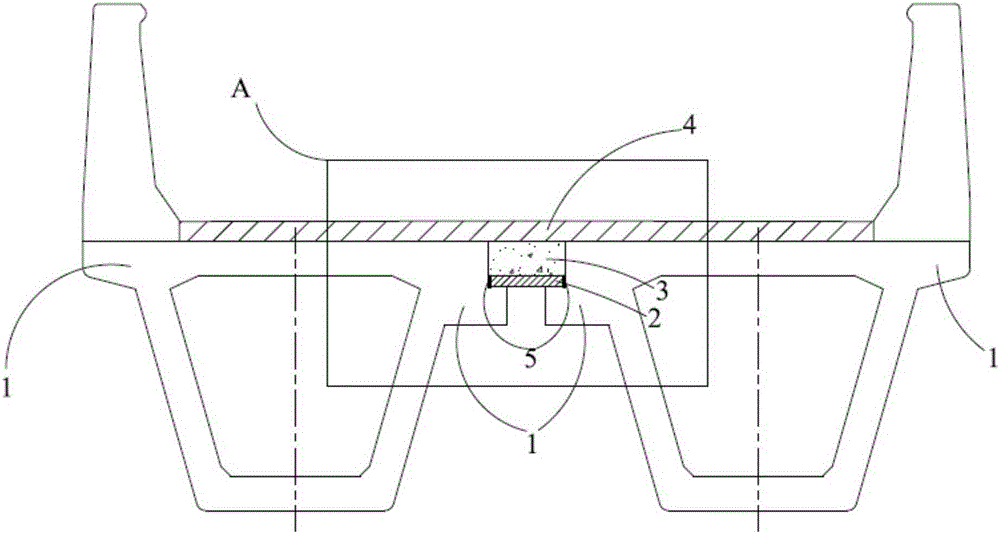

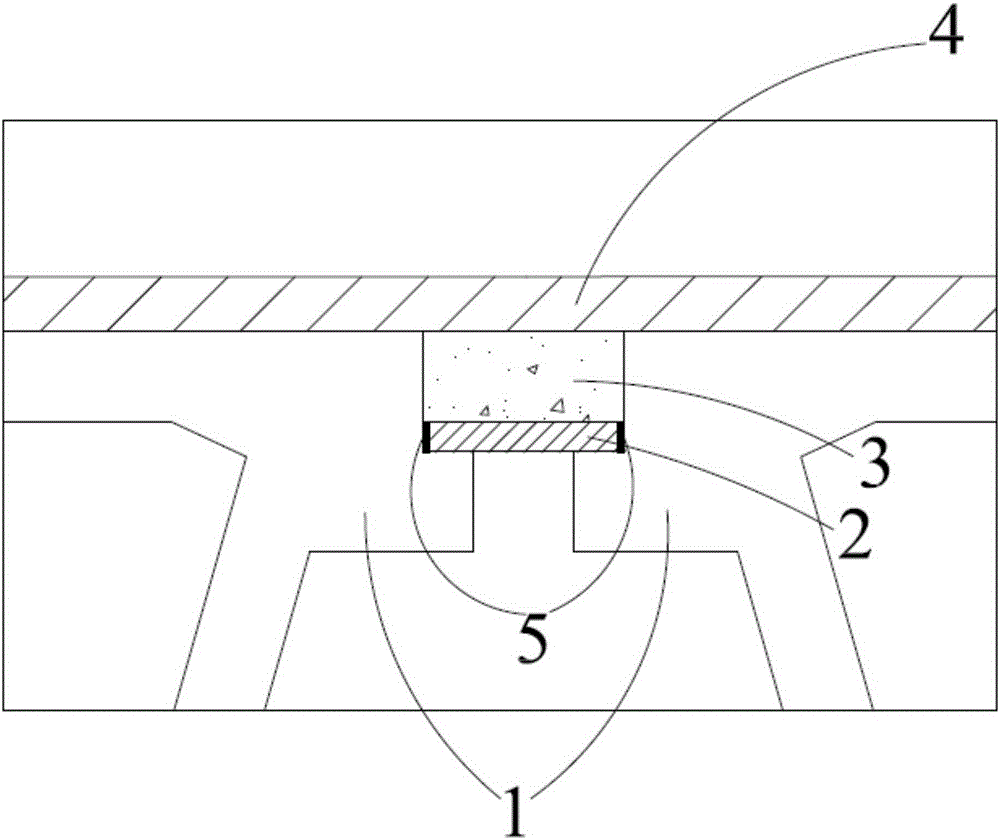

[0025] Such as figure 1 Shown is the structural representation of the embodiment of the closed structure of two transversely connected small box girders in a kind of small box girder bridge provided by the present invention, as figure 2 Shown is provided by the present invention figure 1 The partial enlarged view of part A in the middle is represented by figure 1 and figure 2 It can be seen that in this closed structure:

[0026] The width and depth of the groove can be adjusted according to the actual structure and operating environment of the small box girder, the width can range from 300-1000mm, and the depth can range from 15-25mm. The cross section of the groove can be trapezoidal, U-shaped or rectangular. figure 1 and figure 2 In t...

Embodiment 2

[0034] Embodiment 2 provided by the present invention is an embodiment of a construction method of a small box girder bridge provided by the present invention, and an embodiment of a construction method of a small box girder bridge provided by the present invention includes the following steps:

[0035] Step 1, make and install the small box girder;

[0036] The upper edge of the flange plate at the transverse connection between the manufactured small box girder and another small box girder is provided with a concave angle formed by inward depression; when placed, the two concave angles at the joint of two horizontally connected small box girders combined to form a groove with an upward opening direction;

[0037] Step 2, place a prefabricated plate whose size matches the size of the groove on the bottom surface of the groove;

[0038] Step 3, filling the sealing filler in the gap between the prefabricated panel and the flange panel;

[0039] Step 4, perform cast-in-place we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com