Coal gasification reaction device and reaction system and process based on the device

A reaction device and gasification reaction technology, applied in the field of coal gasification, can solve the problems of low crude gas output, low reaction conversion rate, and unstable operation of gasification reaction, and achieve low reaction conversion rate, low output, and flow field The effect of distribution optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

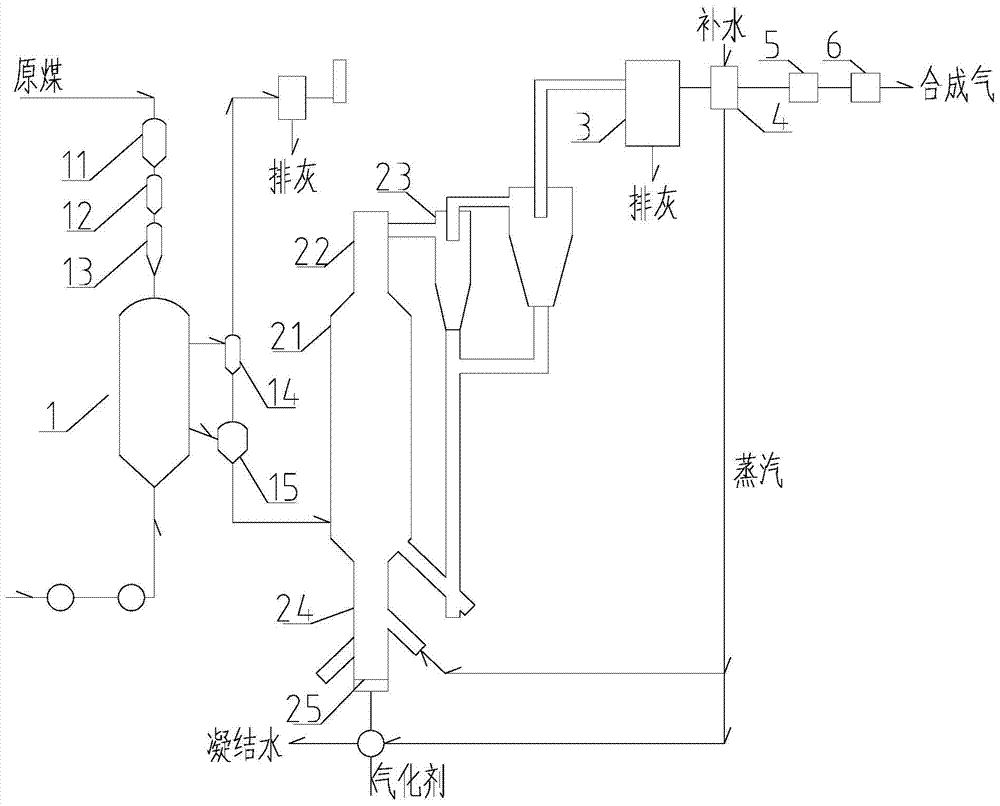

[0037] This embodiment provides a coal gasification reaction system, its structure is as follows figure 1 As shown, the sequential connection arrangement includes: a raw coal preheater 1, a coal gasification reaction device, a separation and dust removal device, and a spray purification unit 5.

[0038] The raw coal preheater 1 is used to preheat the raw coal. The top of the raw coal preheater 1 is provided with a raw coal input port, the bottom is provided with a high-temperature flue gas input port, the lower part is provided with a coal outlet, and the upper part is provided with a Flue gas output port; upstream of the raw coal preheater 1, it is sequentially connected with the raw coal input port of the raw coal preheater 1, and is provided with a crushing chamber 11, a sorting chamber 12, and a particle size adjustment chamber 13, which are used for preheating. The raw coal is screened; downstream of the raw coal preheater 1, a dry coal bunker 15 is connected to the coal ...

Embodiment 2

[0052] This embodiment provides a coal gasification reaction system, its structure is as follows figure 1 As shown, the sequential connection arrangement includes: a raw coal preheater 1, a coal gasification reaction device, a separation and dust removal device, and a spray purification unit 5.

[0053] The raw coal preheater 1 is used to preheat the raw coal. The top of the raw coal preheater 1 is provided with a raw coal input port, the bottom is provided with a high-temperature flue gas input port, the lower part is provided with a coal outlet, and the upper part is provided with a Flue gas output port; upstream of the raw coal preheater 1, it is sequentially connected with the raw coal input port of the raw coal preheater 1, and is provided with a crushing chamber 11, a sorting chamber 12, and a particle size adjustment chamber 13, which are used for preheating. The raw coal is screened; downstream of the raw coal preheater 1, a dry coal bunker 15 is connected to the coal ...

Embodiment 3

[0067] This embodiment provides a coal gasification reaction system, including: a raw coal preheater 1 , a coal gasification reaction device, a separation and dust removal device, and a gas purification unit 5 .

[0068] The raw coal preheater 1 is used to preheat the raw coal. The top of the raw coal preheater 1 is provided with a raw coal input port, the bottom is provided with a high-temperature flue gas input port, the lower part is provided with a coal outlet, and the upper part is provided with a Smoke outlet.

[0069] The coal gasification reaction device is connected to the coal outlet of the raw coal preheater 1, and the coal gasification reaction device includes a first straight pipe gasification section 21, a second straight pipe gasification section 22 and a gas-solid separation device twenty three.

[0070] The diameter ratio of the first straight pipe gasification section 21 to the second straight pipe gasification section 22 is 3:1; the aspect ratio of the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com