A kind of amphoteric phenolic resin high temperature drilling fluid fluid loss reducer and preparation method thereof

A technology of phenolic resin and fluid loss reducing agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of low utilization rate of treatment agent, waste of raw materials, large amount of addition, etc., and achieves that the reaction rate is not easy to control, The effect of increasing adsorption capacity and reducing salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

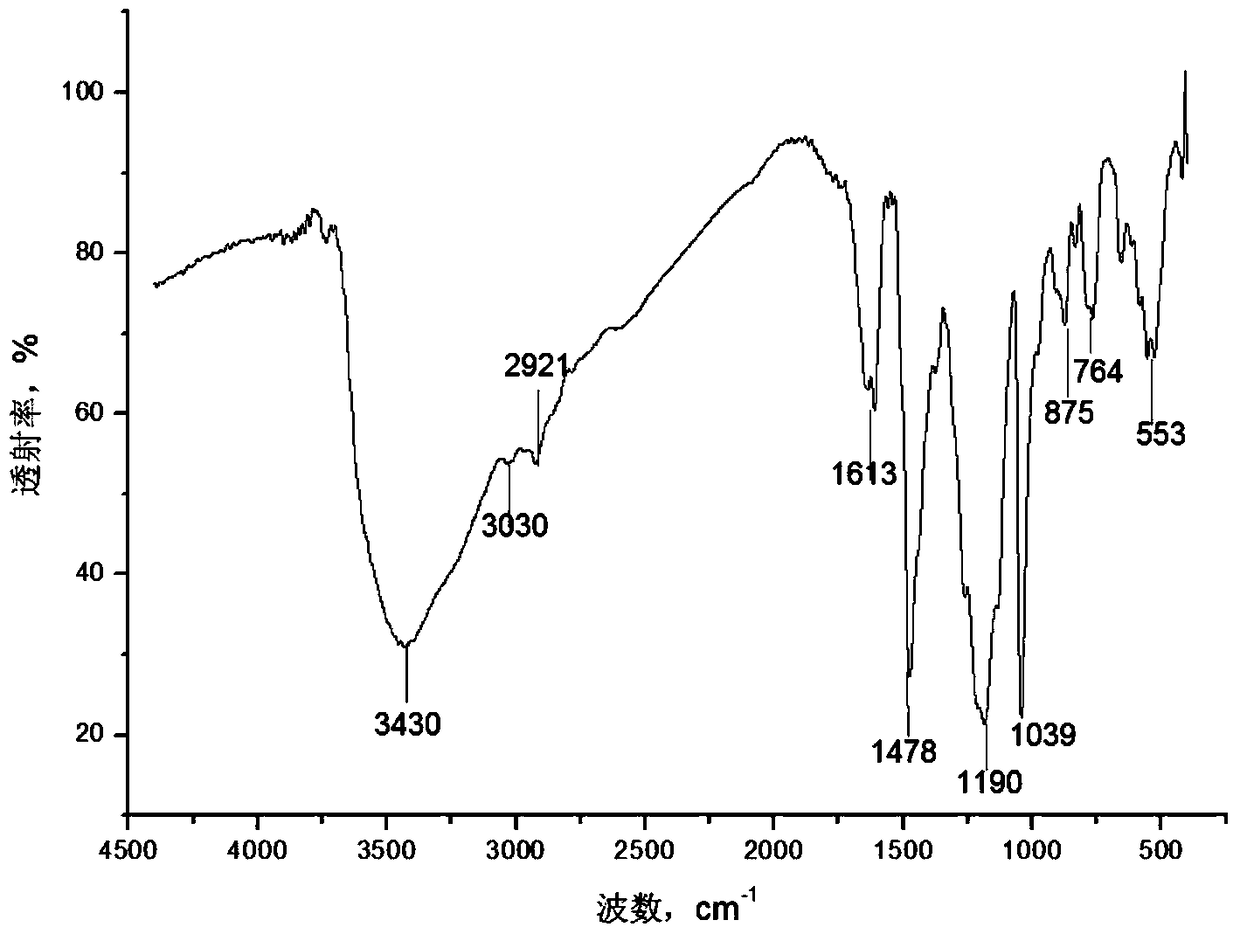

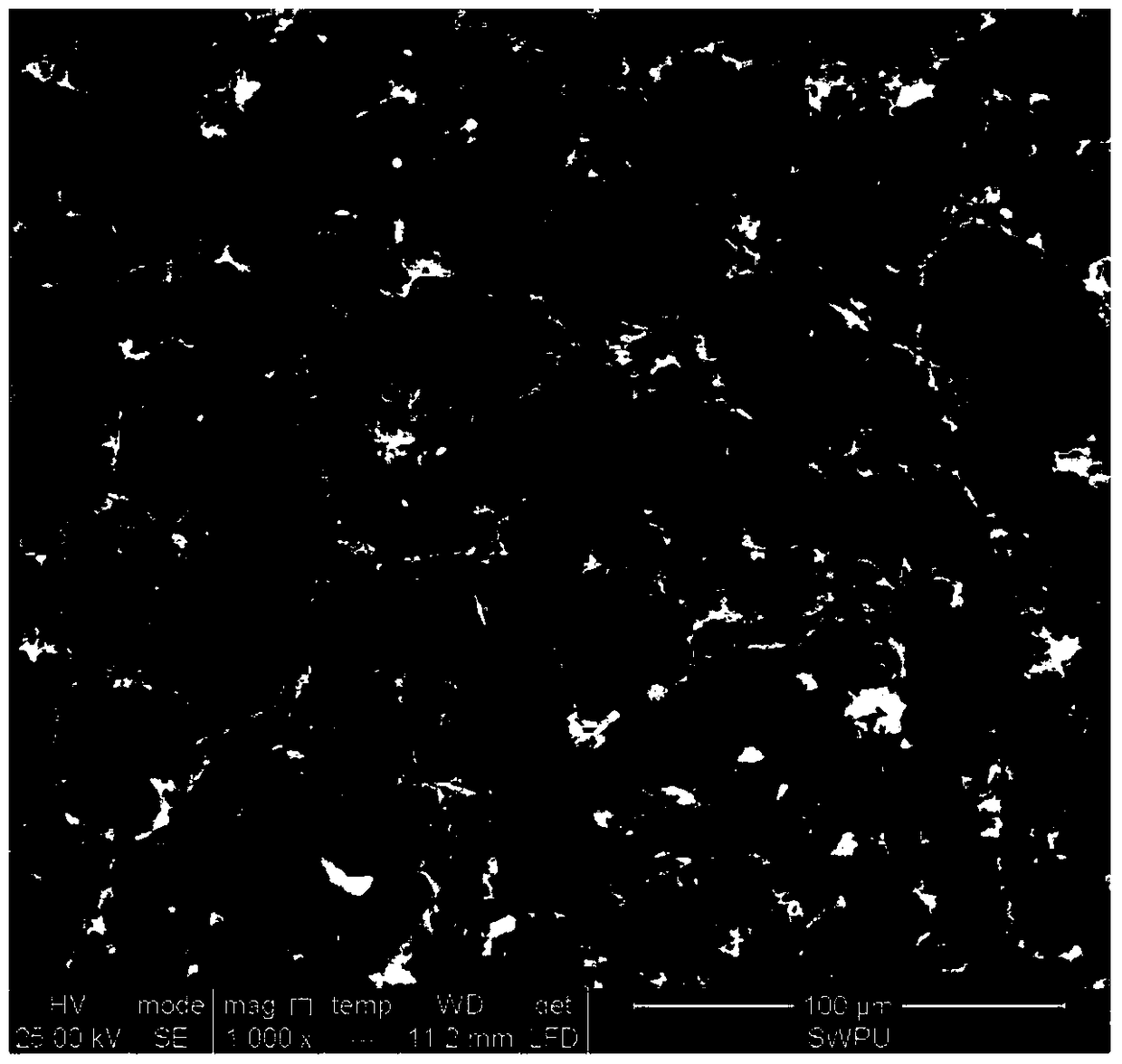

Method used

Image

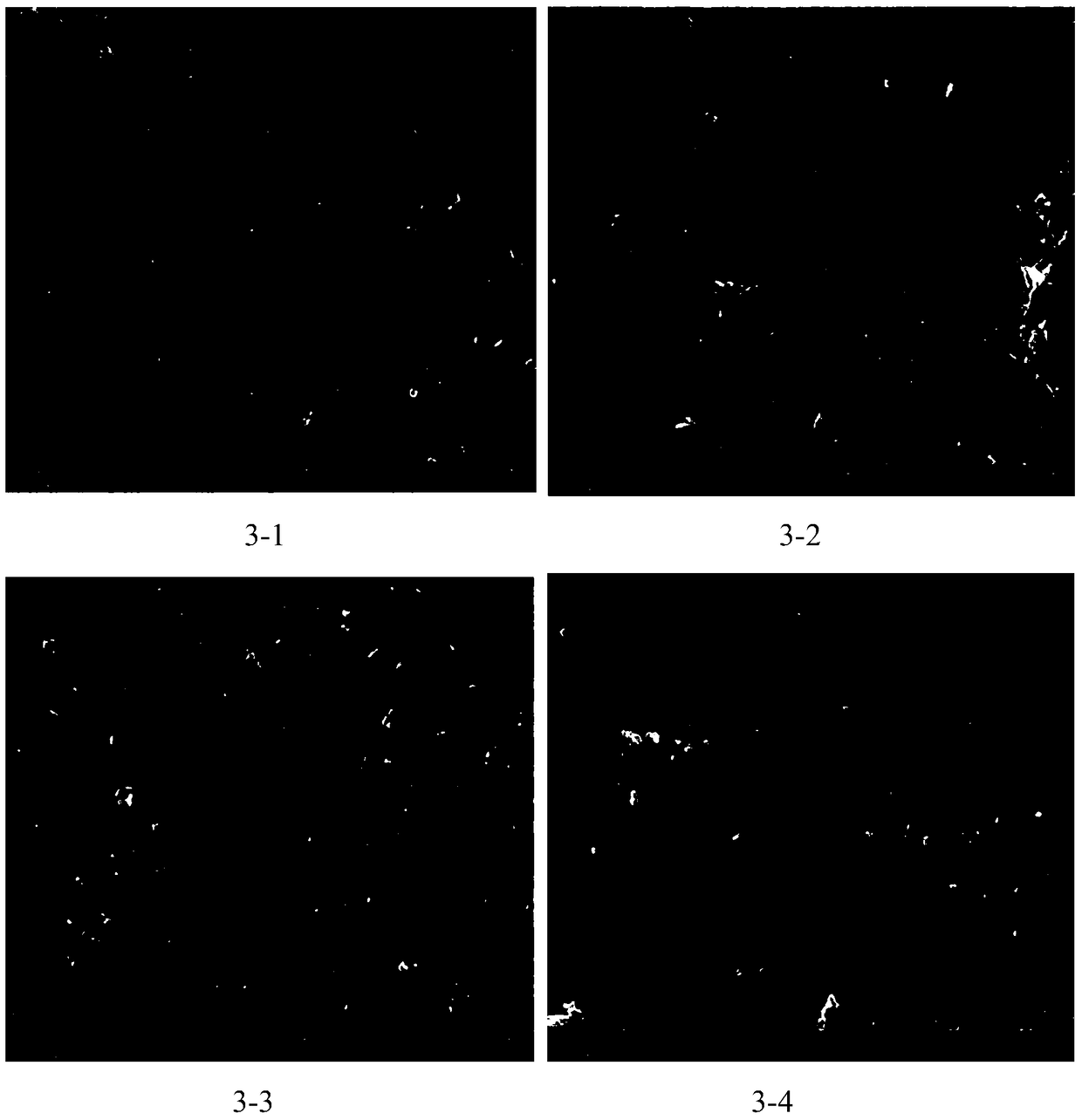

Examples

Embodiment 1

[0024] An amphoteric phenolic resin high-temperature drilling fluid fluid loss reducer, the preparation method of which comprises the following steps:

[0025] (1) Preparation of cationized linear resin

[0026] Add 10.8g, 9.8g, and 2.0g of phenol, formaldehyde, and hordenine into the reaction vessel, stir evenly at room temperature, adjust the pH value of the solution to 3 with hydrochloric acid, then raise the temperature to 80°C, and stir and reflux at this temperature for 60 minutes. At this time, the solution becomes turbid and ready for use;

[0027] (2) Preparation of sulfomethylating agent

[0028] Mix 26.5g of sodium metabisulfite with 26.5g of distilled water, add 21.2g of formaldehyde solution dropwise under stirring, raise the temperature of the water bath to 50°C after the dropwise addition, and react at a constant temperature for 4 hours; because the reaction is exothermic, formaldehyde should be added dropwise, not one-time access;

[0029] (3) Preparation of...

Embodiment 2

[0032] An amphoteric phenolic resin high-temperature drilling fluid fluid loss reducer, the preparation method of which comprises the following steps:

[0033] (1) Preparation of cationized linear resin

[0034] Take 16.2g, 15.1g, and 28.5g of phenol, formaldehyde, and hordenine respectively and add them to the reaction vessel, stir evenly at room temperature, adjust the pH value of the solution to 3 with hydrochloric acid, then raise the temperature to 75°C, stir and reflux at this temperature for 60 minutes, At this time, the solution becomes turbid and ready for use;

[0035] (2) Preparation of sulfomethylating agent

[0036] Take 26.5g of sodium metabisulfite and 26.5g of distilled water and mix well, add dropwise 21.2g of formaldehyde solution under stirring, after the dropwise addition, raise the temperature of the water bath to 50°C, and react at constant temperature for 4 hours; because the reaction is exothermic, formaldehyde should be added dropwise gradually, not ...

Embodiment 3

[0040] An amphoteric phenolic resin high-temperature drilling fluid fluid loss reducer, the preparation method of which comprises the following steps:

[0041] (1) Preparation of cationized linear resin

[0042] Take 16.2g, 15.1g, and 28.5g of phenol, formaldehyde, and hordenine respectively and add them to the reaction vessel, stir evenly at room temperature, adjust the pH value of the solution to 4 with hydrochloric acid, then raise the temperature to 70°C, stir and reflux at this temperature for 60 minutes, At this time, the solution becomes turbid and ready for use;

[0043] (2) Preparation of sulfomethylating agent

[0044]Take 22.5g of sodium metabisulfite and 22.5g of distilled water and mix well, add dropwise 18.2g of formaldehyde solution under stirring, after the dropwise addition, raise the temperature of the water bath to 50°C, and react at constant temperature for 4 hours; because the reaction is exothermic, formaldehyde should be added dropwise gradually, not o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com