Railway vehicle chassis end structure

A technology for rail vehicles and end structures, which is applied to the underframe, railway car body parts, railway couplings, etc., can solve the problems of cumbersome manufacturing process, interface interference, and high coupler height, optimize the welding interface relationship, and enhance the strength. , the effect of making convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

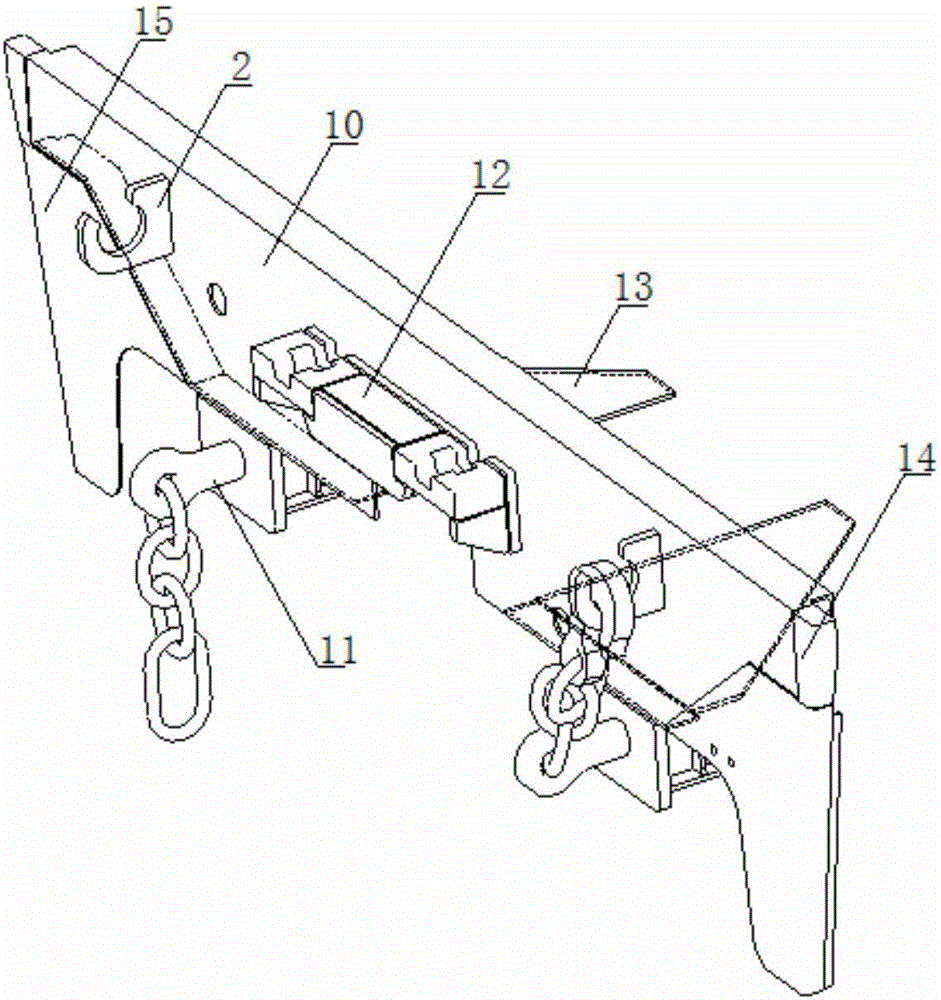

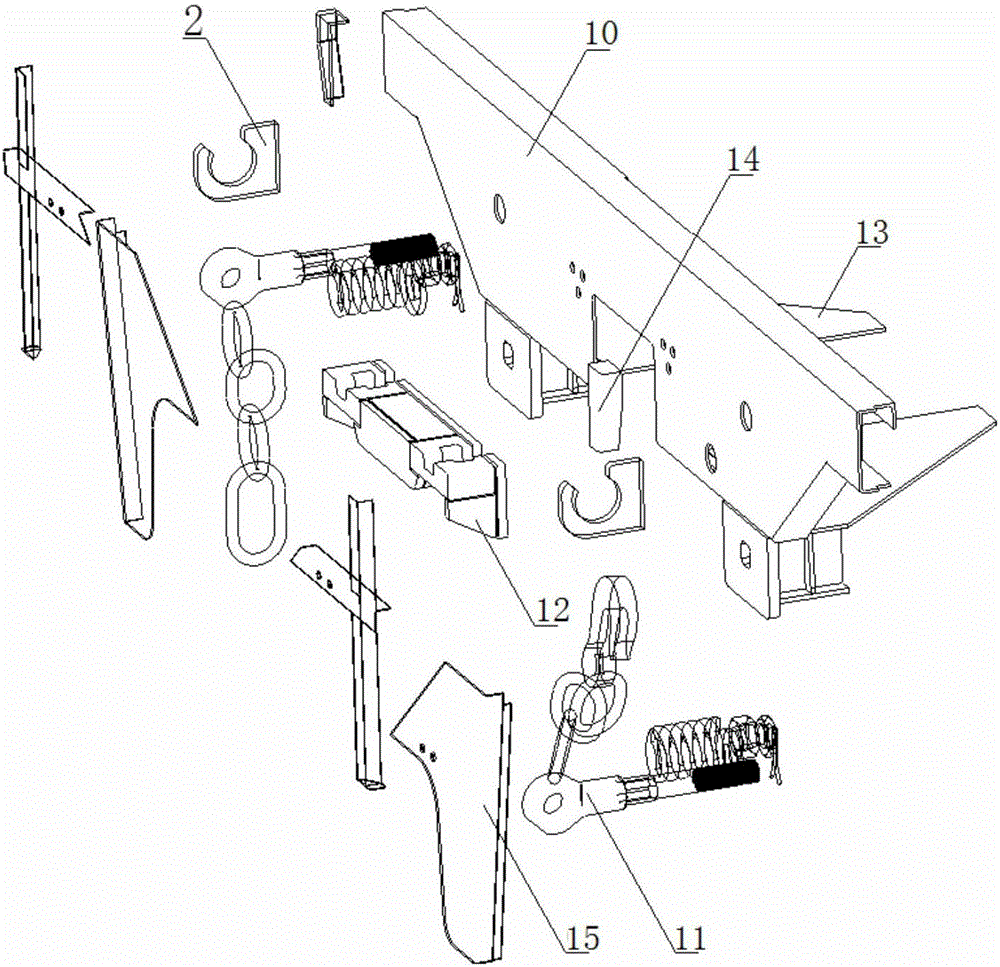

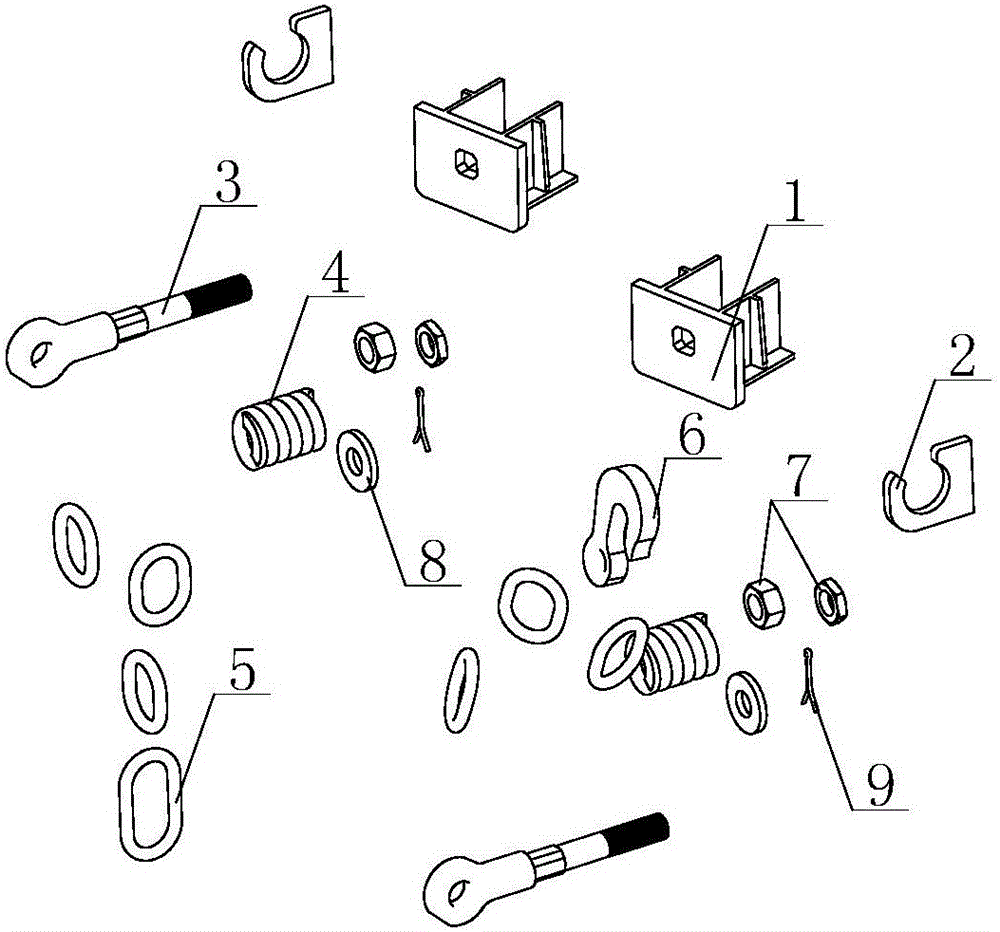

[0023] Such as Figure 1 to Figure 6 As shown, the end structure of the underframe of the rail vehicle in this embodiment consists of: an end beam 10 , a draw beam 17 and a corrugated floor 16 , and the end beam 10 is provided with a decoupling protection device 11 and an anti-jump impact seat 12 . The decoupling protection device 11 is arranged under the end beam 10, including: two protective boxes 1 symmetrically fixed under the end beam, safety chain rods 3 respectively inserted into the two protective boxes 1 and elastically fixed, respectively connected to the two safety chains The chain hook 6 and chain ring 5 on the bar 3, the rear end of the safety chain bar 3 is screwed with a nut 7, the front end of the nut 7 is provided with a stop block 8 that is enclosed within the safety chain bar 3, and the safety chain bar 3 is also sleeved with a The two ends are respectively against the spring 4 of the inner wall of the front side of the protective box 1 and the stopper 8; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com