A jig for processing a forklift gearbox case

A gearbox and box technology, applied in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of large fluctuation range of pressing force, lack of lateral support, unreasonable pressing method of box body, etc. Achieve the effect of reducing the requirements of personnel operating skills, reducing the risk of workpiece deformation, and ensuring the quality of product processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

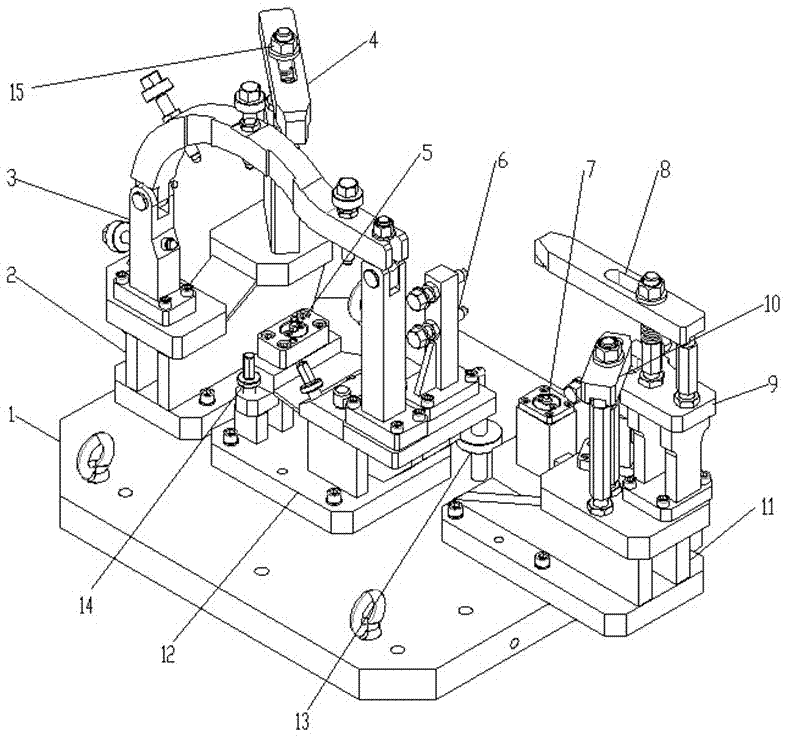

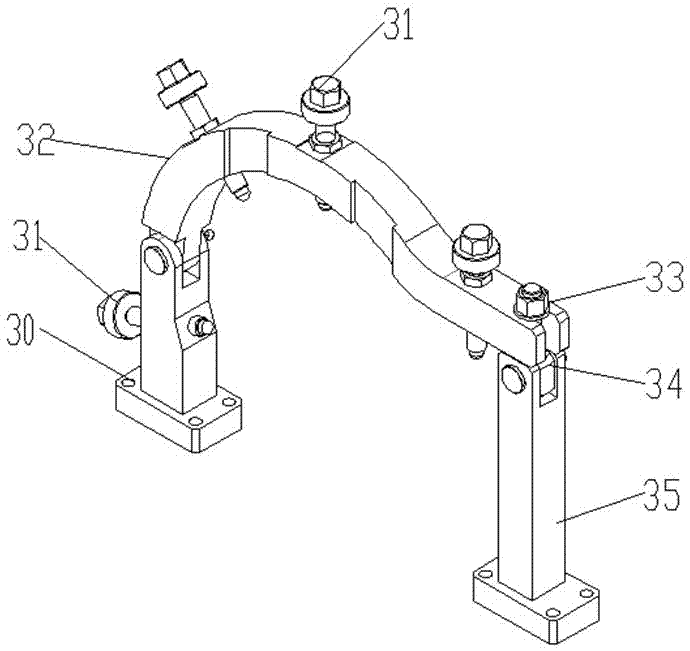

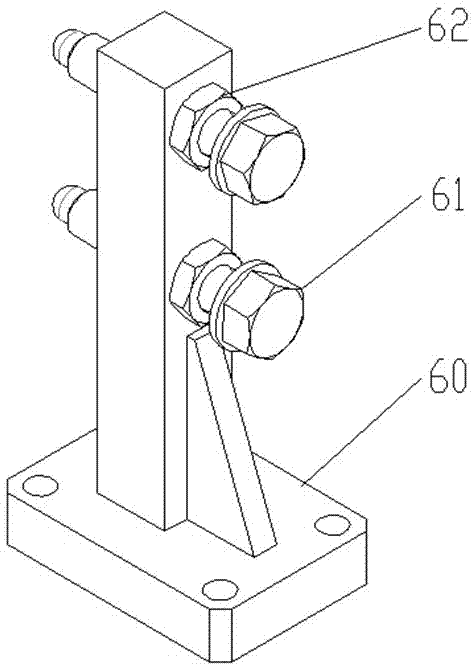

[0038] see figure 1 , a fixture for the processing of a forklift gearbox box includes a bottom plate 1, a left platen mechanism, an intermediate mechanism and a right platen mechanism are respectively installed on the bottom plate 1, and first positioning pins 5 are also installed on the bottom plate 1 on both sides of the intermediate mechanism And the second positioning pin 7. The left platen mechanism includes an arc-shaped platen 32 and a left platen 4. The left platen mechanism also includes a left platen seat 2. The top of the left platen seat 2 is provided with two installation platforms, one side is an arc-shaped platen installation platform, and the other side is a left platen. Press plate installation platform, and the left press plate installation platform is higher than the curved press plate installation platform. see figure 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com