Automatic wire arranging welding device

A welding device and automatic wiring technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as difficulty in ensuring welding quality, increasing welding difficulty, and complicated manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

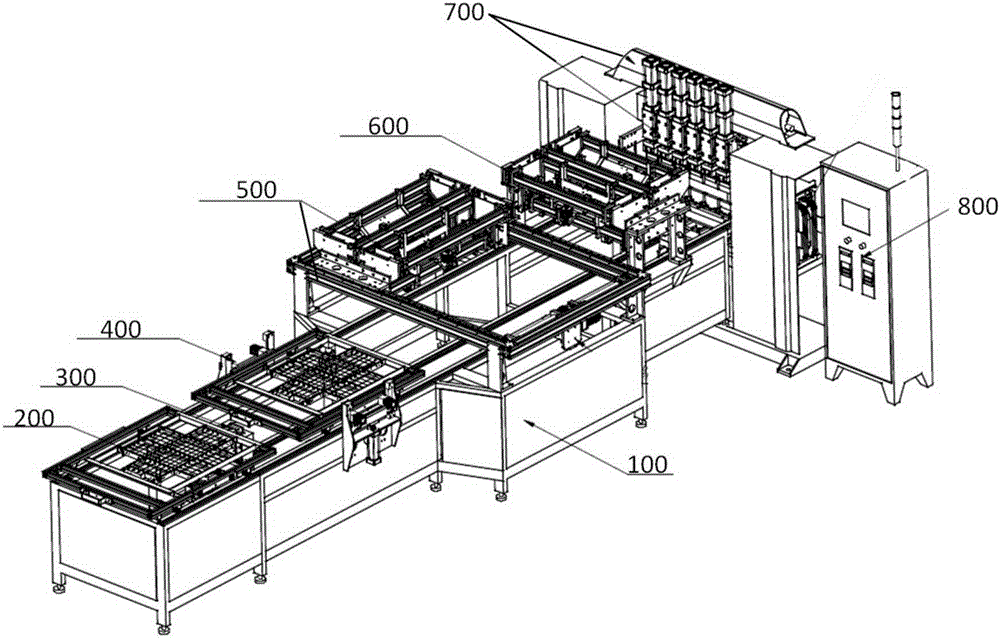

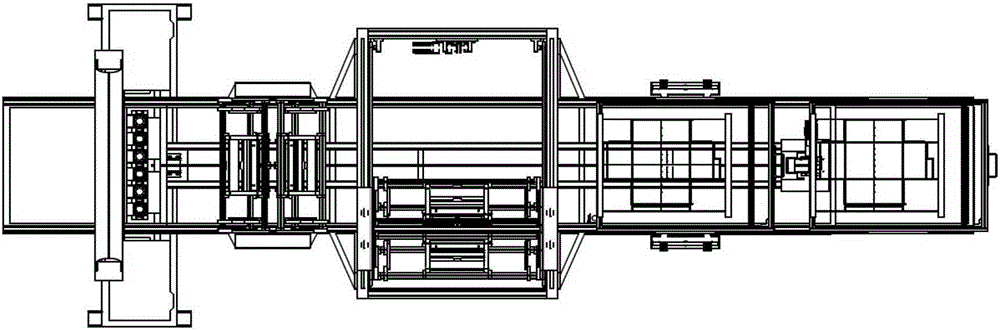

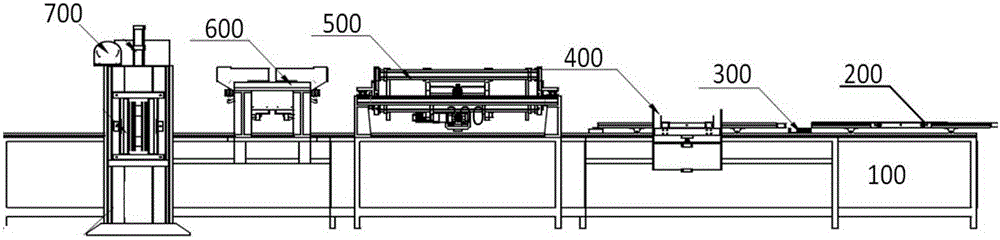

[0053] As attached figure 1 Attached image 3 As shown, the automatic wiring welding device of the present invention as a whole includes an automatic welding system 700, a horizontal wiring system 600, a vertical wiring system 500, a support main body 100, a material rack lifting system 400, a material rack moving system 300, a welding material rack 200 and Control system 800. The bracket body 100 serves as a support frame for the entire device. A material rack lifting system 400, a vertical wiring system 500, and a horizontal wiring system 500 are sequentially arranged on the bracket body 100 along the length direction of the bracket body 100 (from front to back). Wiring system 600 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com