A thermophoretic coupled submicron particle sorter

A submicron particle and sorter technology, applied in the field of microfluidic systems, can solve the problems of poor sorting efficiency, low sorting precision, and difficulty in adapting to submicron particle sorting, so as to improve sorting precision and efficiency , is conducive to the effect of pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

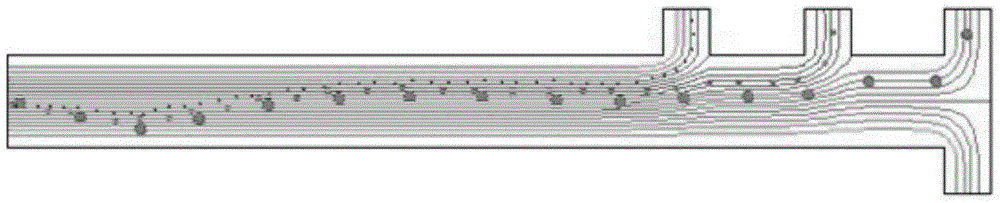

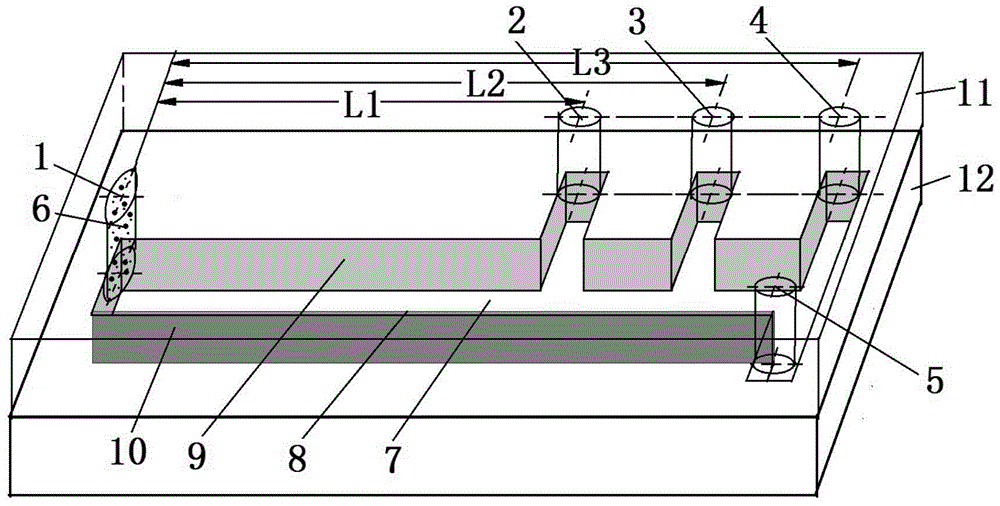

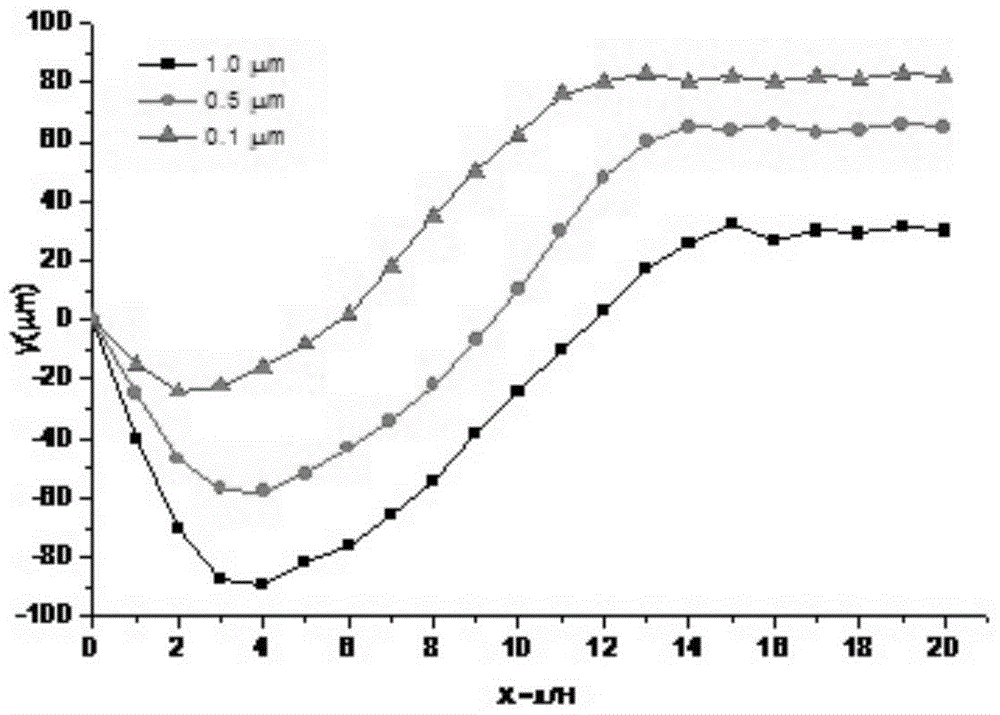

[0027] Example 1, the number of sorting stages is three, assuming that an aqueous solution containing particles of 0.1, 0.5, and 1.0 microns is introduced at the inlet 1, and the particle density is 1050 kg / m 3 , the inlet speed is 10mm / s, after entering the sorting channel with a height of 200 microns, the separation is carried out, the temperature difference between the upper and lower walls is controlled at 10 degrees, and the particles of 0.1, 0.5 and 1.0 microns start at 2~3 mm downstream of the sorting channel. Focus on 82, 63, and 30 microns above the centerline of the sorting channel, and export at exit 2, exit 3, and exit 4, respectively.

Embodiment 2

[0028] Example 2, the number of sorting stages is three, assuming that an aqueous solution containing particles of 0.1, 0.5, and 1.0 microns is introduced at inlet 1, and the particle density is 1050 kg / m 3 , the inlet speed is 10mm / s, and sorting is carried out after entering the sorting channel with a height of 200 microns. When the temperature difference between the upper and lower walls is controlled at 2 degrees, the particles of 0.1, 0.5, and 1.0 microns are respectively focused on the center line of the sorting channel 62 , 36, and -30 microns are exported at outlet 2, outlet 3 and outlet 5, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com