Preparation method and application of potassium-doped mesoporous g-C3N4 photocatalytic material

A photocatalytic material, g-c3n4 technology, applied in the field of photocatalytic materials, can solve problems such as unfavorable environmental protection and large-scale preparation, low efficiency of organic pollutants, cumbersome synthesis process, etc., achieves excellent photocatalytic performance, is conducive to Environmental protection and large-scale application, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] 1. Preparation of SBA-15

[0021] According to reports by Zhao Dongyuan et al. in J.Am.Chem.Soc.Vol.120(1998)pp.6024-6036, the preparation method of SBA-15 is as follows: 4.0g of P123 is dissolved in 30g of water and 120g of hydrochloric acid (2M) , and the mixed solution was stirred at 35° C. for 2.5 h. Then add 8.50g of TEOS and continue to stir for 20h. Then the mixture was placed in an oven at 80 °C for 24 h. The mixture was filtered, washed with water, and dried at room temperature. Remove the surfactant in the channel by Soxhlet extractor extraction, use HCl (37wt% aqueous solution) / EtOH (V HCl / EtOH =1.5 / 98.5) as the extract.

[0022] 2. Potassium-doped mesoporous g-C 3 N 4 preparation of

Embodiment 1

[0023] Example 1: 20% potassium doped mesoporous g-C 3 N 4 preparation of

[0024] Weigh 5g of melamine and 1.66g of KI respectively, after fully grinding, weigh 3.0g of the mixture and put it into the bottom of the corundum crucible, and then evenly disperse 10.0g of SBA-15 on the mixture of melamine and KI. Cover the crucible and place it in a muffle furnace for calcination. Raise the temperature to 320°C for 4 hours at a rate of 10K / min. During this process, the mixture of melamine and KI will evaporate into the pores of the mesoporous material SBA-15, and then increase the temperature to 550°C at a rate of 2K / min. ℃ for 4 hours, then cooled down to room temperature naturally. The resulting product was removed with 5% hydrofluoric acid to remove the template, then fully washed with deionized water and ethanol until the pH value was 7, and dried at 60°C for 5 hours to obtain mesoporous K-doped C 3 N 4 .

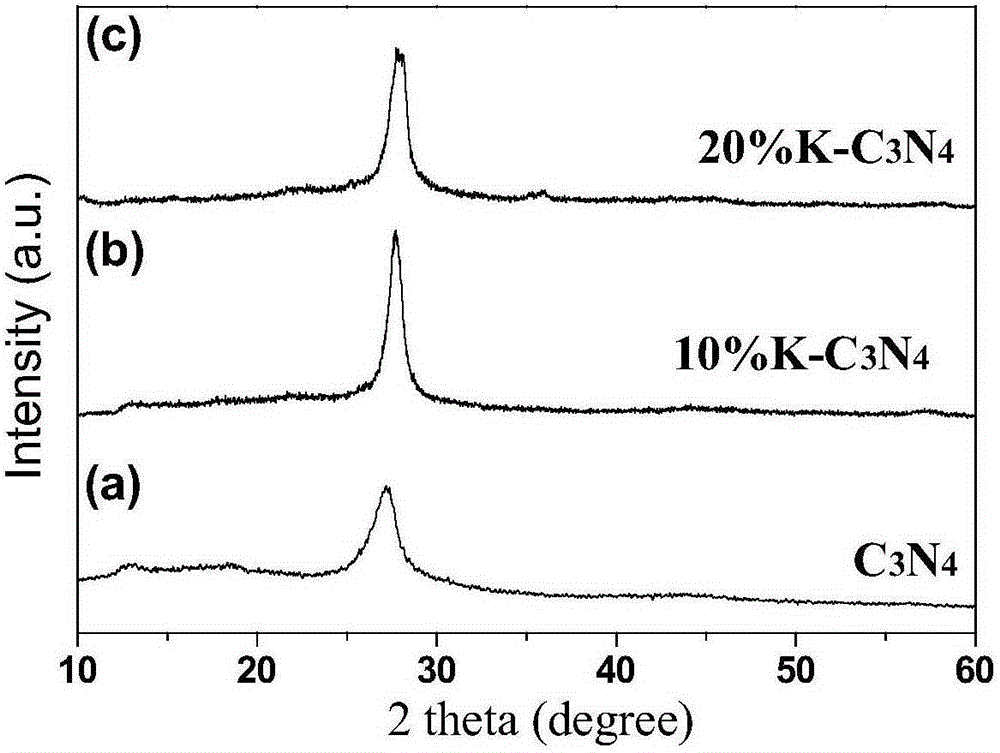

[0025] XRD analysis shows ( figure 1 ), the prepared potassium ...

Embodiment 2

[0026] Example 2: 10% potassium doped mesoporous g-C 3 N 4 preparation of

[0027] Weigh 5g of melamine and 0.73g of KI respectively, after fully grinding, weigh 3.0g of the mixture and put it into the bottom of the corundum crucible, and then evenly disperse 10.0g of SBA-15 on the mixture of melamine and KI. Cover the crucible and place it in a muffle furnace for calcination. Raise the temperature to 320°C for 4 hours at a rate of 10K / min. During this process, the mixture of melamine and KI will evaporate into the pores of the mesoporous material SBA-15, and then increase the temperature to 550°C at a rate of 2K / min. ℃ for 4 hours, then cooled down to room temperature naturally. The resulting product was removed with 5% hydrofluoric acid to remove the template, then fully washed with deionized water and ethanol until the pH value was 7, and dried at 60°C for 5 hours to obtain mesoporous K-doped C 3 N 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com