Fish feed processing method

A processing method and technology of fish feed, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problem of unclear interaction mechanism and other problems, and achieve the effect of increasing nutritional value, easy digestion, and high degree of ripening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

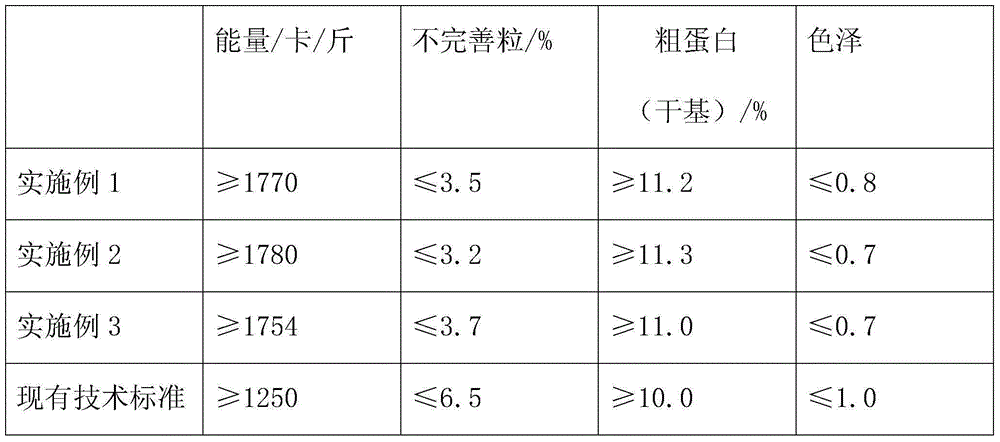

Examples

Embodiment 1

[0028] A kind of fish feed processing method is characterized in that, its step comprises:

[0029] (1) Raw material mixing

[0030] The raw materials are prepared according to the formula of 50% bean cake, 15% fish meal, 15% bran, 15% rice bran, 1% vitamin, 1% inorganic salt, 1% antibiotic waste, and 2% adhesive, and add 0.8% to the raw material formula Peptide concentrate, and then mix the raw materials and 8% water evenly in a mixer, the speed of the mixer is 600r / min, and the time is 25min;

[0031] (2) ripening

[0032] The raw material is matured by steam, the curing temperature is 100°C, and the time is 30 minutes. After the raw material is matured, it is pre-dried, and the drying temperature is 50°C, and the time is 15 minutes;

[0033] (3) Granulation

[0034] The mixed raw materials are fed into the screw extrusion granulator, and the powdery raw materials are prepared into granular raw materials through the granulator. The process parameters of the granulator are...

Embodiment 2

[0046] A kind of fish feed processing method is characterized in that, its step comprises:

[0047] (1) Raw material mixing

[0048] The raw materials are prepared according to the formula of 50% bean cake, 15% fish meal, 15% bran, 15% rice bran, 1% vitamin, 1% inorganic salt, 1% antibiotic waste, and 2% adhesive, and add 0.8% to the raw material formula Peptide concentrate, and then mix the raw materials and 12% water in a mixer, the speed of the mixer is 800r / min, and the time is 20min;

[0049] (2) ripening

[0050] The raw material is matured by steam, the curing temperature is 110°C, and the time is 35 minutes. After the raw material is matured, it is pre-dried, and the drying temperature is 50°C, and the time is 15 minutes;

[0051] (3) Granulation

[0052] The mixed raw materials are fed into the screw extrusion granulator, and the powdery raw materials are prepared into granular raw materials through the granulator. The process parameters of the granulator are: scre...

Embodiment 3

[0064] A kind of fish feed processing method is characterized in that, its step comprises:

[0065] (1) Raw material mixing

[0066] The raw materials are prepared according to the formula of 50% bean cake, 15% fish meal, 15% bran, 15% rice bran, 1% vitamin, 1% inorganic salt, 1% antibiotic waste, and 2% adhesive, and add 0.8% to the raw material formula Peptide concentrate, and then mix the raw materials and 15% water in a mixer, the speed of the mixer is 1000r / min, and the time is 25min;

[0067] (2) ripening

[0068] The raw material is matured by steam, the curing temperature is 120°C, and the time is 45 minutes. After the raw material is matured, it is pre-dried, and the drying temperature is 50°C, and the time is 15 minutes;

[0069] (3) Granulation

[0070] The mixed raw materials are fed into the screw extrusion granulator, and the powdery raw materials are prepared into granular raw materials through the granulator. The process parameters of the granulator are: scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com