Accelerator power supply apparatus of electron beam microfabrication equipment and control method thereof

A technology for microfabrication and power supply devices, which is applied in the direction of output power conversion devices, conversion equipment that can be converted to DC without intermediate conversion, electrical components, etc., and can solve the acceleration of electron beam micromachining equipment and the peak voltage at the output end of the acceleration power supply And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

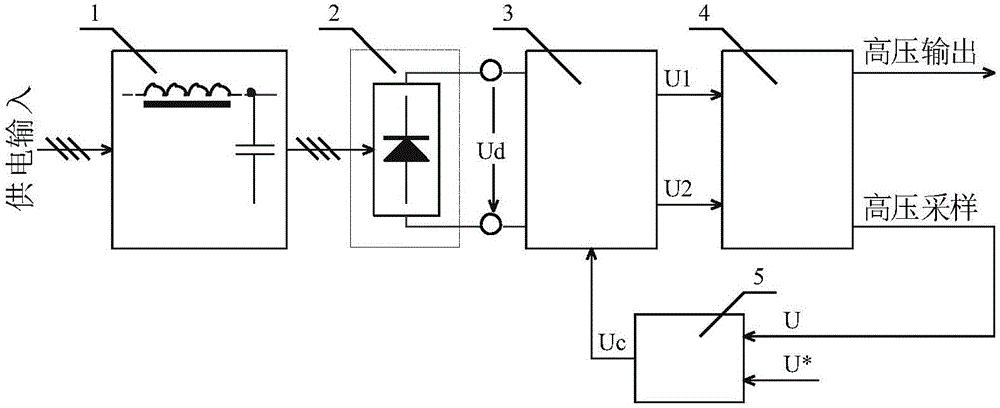

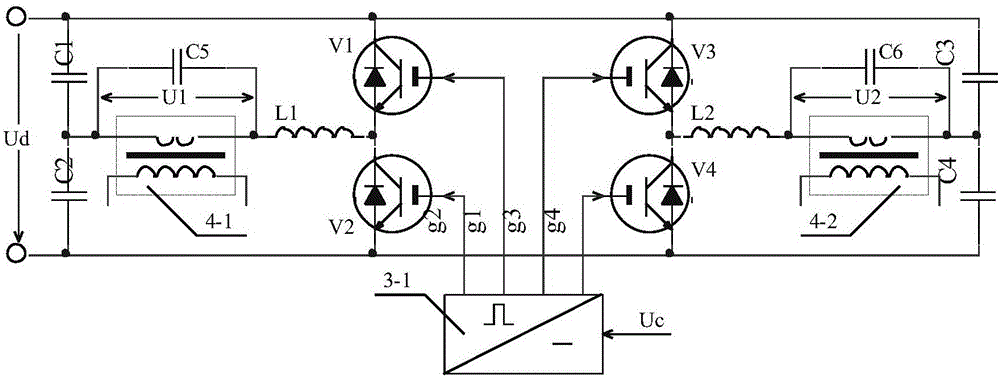

[0051] An accelerating power supply device for electron beam micromachining equipment, including a line filter 1, a low-voltage rectifier bridge 2, an inverter unit 3, a high-voltage unit 4, and a regulator 5, and the input end of the line filter 1 is connected to an external power grid , the output end of the line filter 1, the low-voltage rectifier bridge 2, the inverter unit 3 and the input end of the high-voltage unit 4 are connected in series in sequence, the high-voltage output end of the high-voltage unit 4 outputs high-voltage electricity, and the high-voltage unit 4 The high-voltage feedback signal U output from the signal terminal is sent to the second input terminal of the regulator 5, and the first input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com