Manufacturing method of antenna and antenna structure

A manufacturing method and technology of antenna structure, which are applied in the direction of radiating element structure, antenna support/installation device, etc., can solve the problems of wasting mobile phone space, labor cost and high material cost, achieve small use space, reduce artificial assembly errors, guarantee Effects of Stability and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

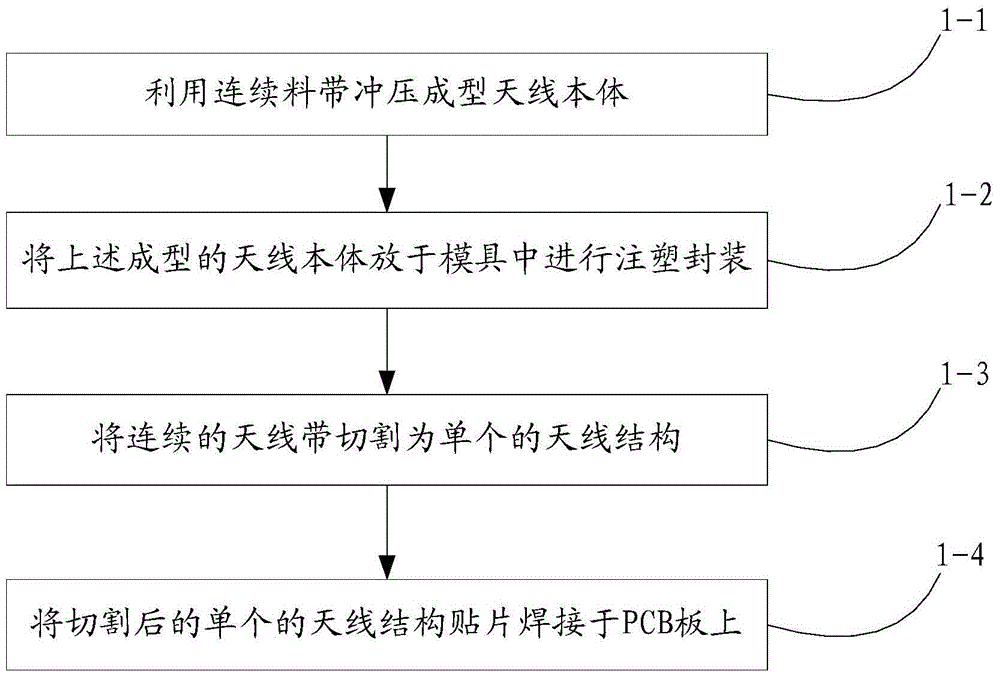

[0040] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0041] The invention discloses a method for manufacturing an antenna, and the antenna can be used in various electronic devices such as mobile phones and palmtop computers. include:

[0042] 1-1: The antenna body is stamped and formed with a continuous strip;

[0043] The strip is nickel-nickel metal strip, which has good weldability and is not easy to be corroded.

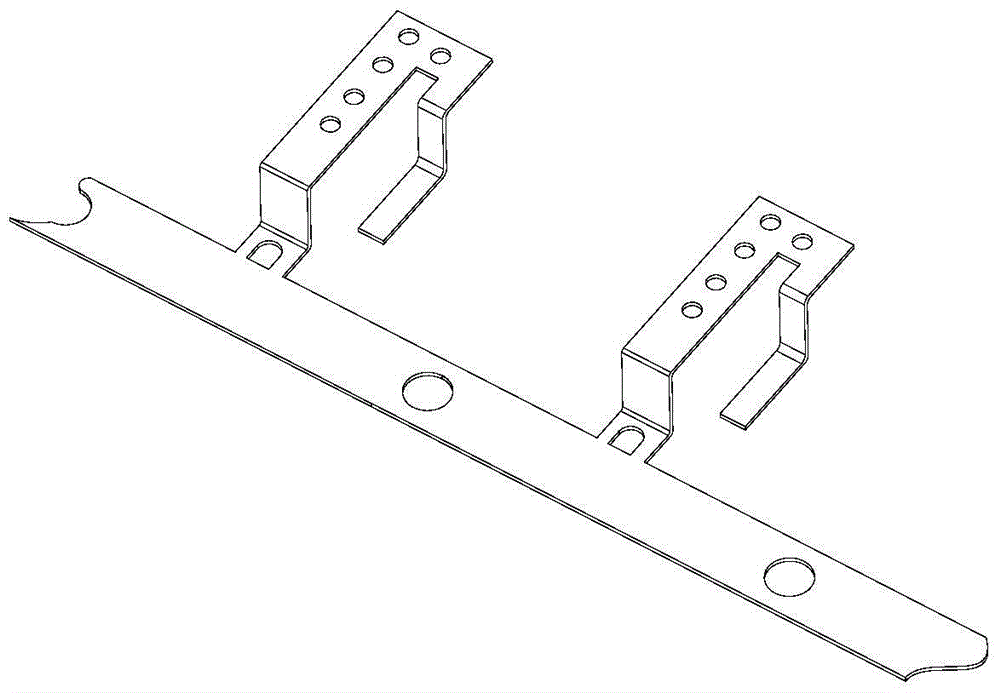

[0044] Refer to attached figure 2 shown, with figure 2 It shows a schematic diagram of the structure of the antenna body formed by stamping the continuous strip; in this step, preferably, the antenna body includes a main body, a first end provided with a welding point for welding with the PCB board, the main body Connected to the first end, preferably, the first end is L-shaped, and the main body includes a second end with a plurality of openings and a third end with a gradient shape.

[0045] 1-2: Put the antenna body formed in ...

Embodiment 2

[0052] An antenna structure can be obtained through the manufacturing method of Embodiment 1, and is suitable for various electronic devices such as mobile phones and palmtop computers. It includes an antenna body and an injection molding part. The antenna body includes a main body covered by the injection molding part, and a first end suspended outside the injection molding part. Preferably, the first end is L-shaped. The bottom surface of the first end is provided with welding points. The first end can be welded to the PCB through the welding point. The main body part includes a second end with a plurality of openings and a third end with a gradient shape; the openings are exposed from the injection molding part and can be used for circuit connection. A groove can be provided on the bottom surface of the injection molding part, and the material of the injection molding part can withstand high temperature above 240°C.

[0053]To sum up, in the present invention, the require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com