High-power laminated lithium battery aluminum casing structure and manufacturing method

A manufacturing method and laminated technology, applied to large-sized batteries/battery packs, manufacturing tools, structural parts, etc., can solve the problems of increasing the battery shell wall, increasing the weight of the battery, and not meeting the lightweight requirements, so as to avoid Larger increase in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

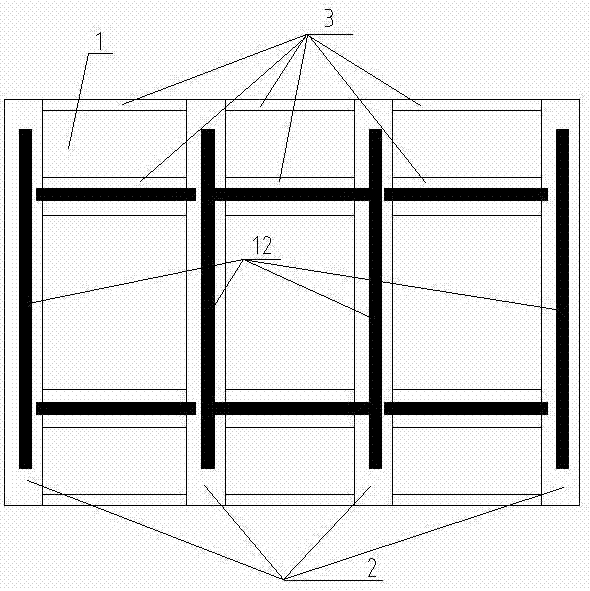

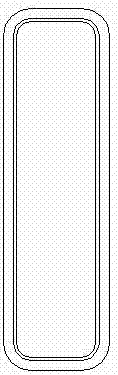

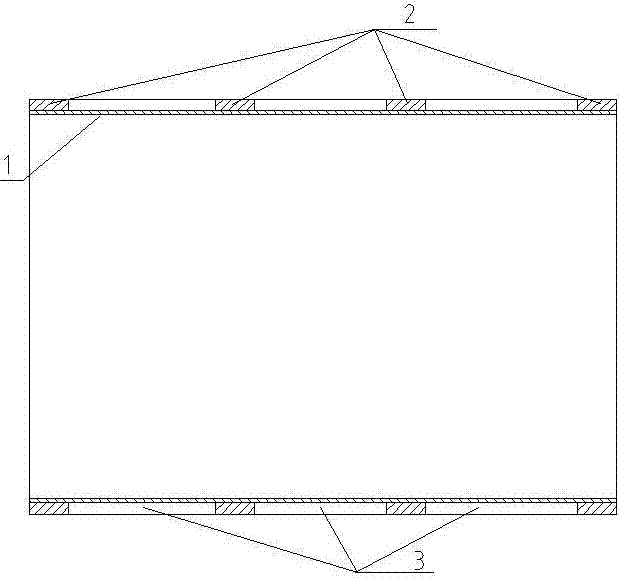

[0031] Such as figure 1 , figure 2 and image 3 As shown, the aluminum casing structure of the high-power laminated lithium battery of the present invention includes a cylindrical casing wall 1 , and the cross section of the casing wall 1 is a rectangle with four rounded corners. The outer surface of the shell wall 1 is provided with a plurality of annular reinforcing ribs 2 sleeved on the cylindrical shell wall. Preferably, the plurality of annular reinforcing ribs 2 are parallel to each other.

[0032] The rib plate 2 and the shell wall 1 are welded by friction stir welding, and the welds 12 are arranged on the planes of the four sides of the shell wall, avoiding the rounded corners of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com