LED display screen capable of assembling and disassembling display module from front surface

A technology of LED display screen and display module, applied in the direction of identification devices, instruments, etc., can solve problems such as inconvenient disassembly and assembly, and achieve the effect of saving costs, reducing workload, and simplifying disassembly and assembly processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

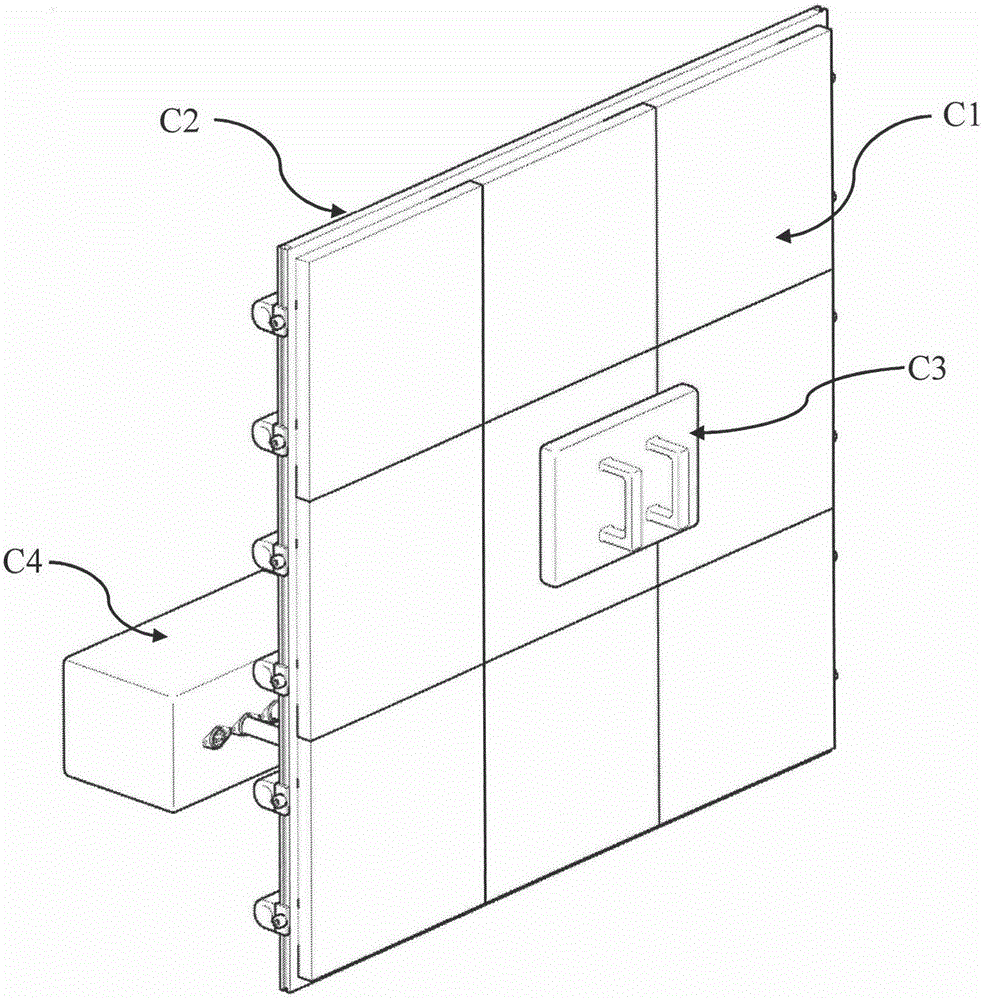

[0057] Such as figure 1 As shown, in an embodiment of the LED display screen of the present invention that can disassemble and assemble the display module from the front, the LED display screen includes a plurality of LED display modules C1, bottom support frame C2, electromagnetic absorption board C3, disassembly and assembly electronic control 器C4.

[0058] Such as figure 2 As shown, a plurality of the LED display modules C1 can be combined with and fixed to the corresponding cell frame of the bottom support frame C2 to form the main display part of the LED display screen; the bottom support frame C2 is rectangular as a whole, using aluminum The profile is cut and welded, and is divided into the cell support frame corresponding to the LED display module C1 in the vertical and horizontal directions, the number, size, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com