Inspection method for electrical equipment

A technology for power equipment and equipment, applied in the field of inspection of power equipment, can solve problems such as lower communication efficiency, missed equipment inspection, data loss, etc., and achieve the effects of ensuring safe operation, improving work efficiency, and good use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

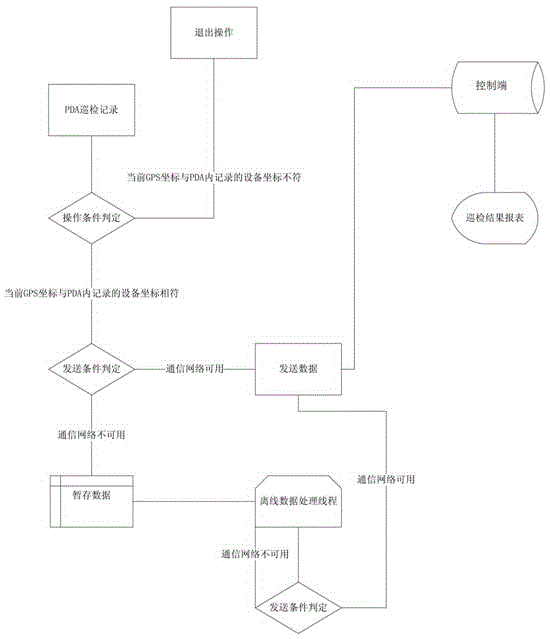

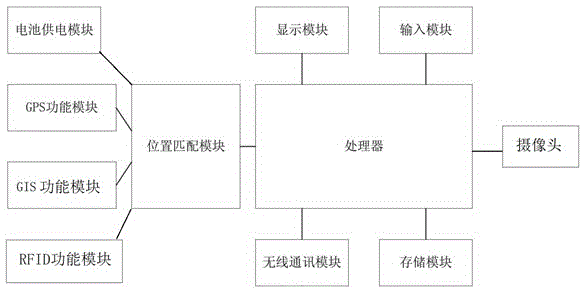

[0020] see Figure 1-2 , a method for inspection of electric power equipment, the specific steps are as follows:

[0021] (1) According to the GIS module set in the handheld device, generate a GIS table for the inspection task, and save the geographic location information of the required inspection equipment;

[0022] (2) The inspection personnel carry handheld devices to carry out on-site inspections according to the GIS table, and obtain the coordinate information of the current device according to the GPS module set in the handheld device;

[0023] (3) Judging whether the coordinate information matches the record in the GIS table, if yes, proceed to the next step, if not, return to step (2);

[0024] (4) Check the current equipment, collect on-site inspection information, record the collected information and save it in the handheld device. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com