Diagnostic circuit and diagnostic method for detecting electric vehicle high-voltage relay fault

A technology of high-voltage relays and electric vehicles, applied in the direction of circuit breaker testing, etc., can solve problems such as impossibility, complexity, and accidents, and achieve the effect of simple and feasible methods without increasing detection risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

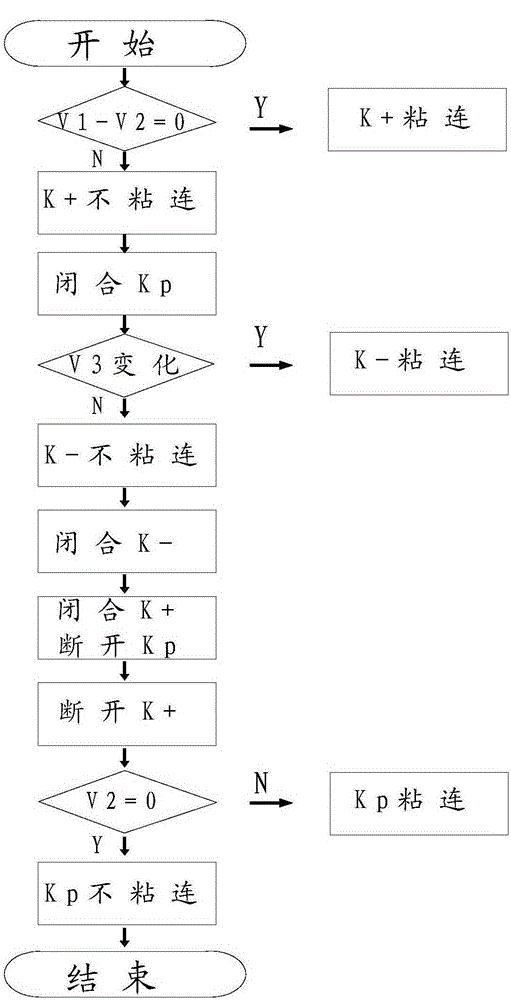

[0014] The present invention will be further described in detail below in conjunction with the description of the drawings.

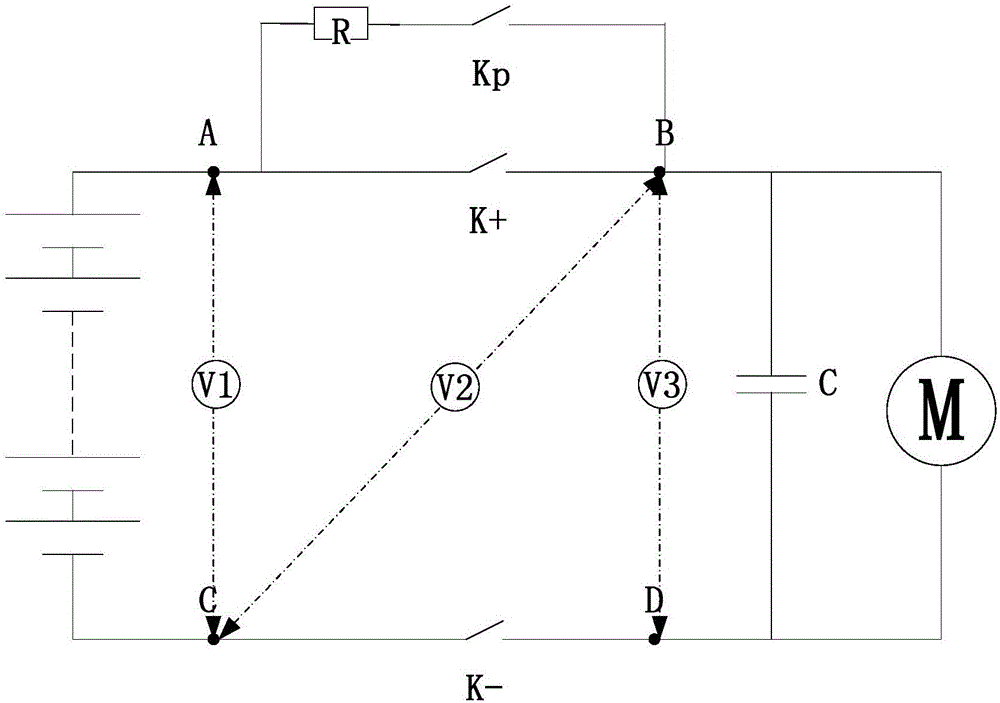

[0015] Such as figure 1 As shown, the diagnostic circuit for detecting the failure of the high-voltage relay of an electric vehicle includes a battery pack that provides power and power for the electric vehicle and a controller that controls the on and off of the electric vehicle relay. The battery pack is composed of multiple batteries in series, and the battery pack has a positive electrode and The negative pole, the two ends of the battery pack are connected to the electrical equipment of the vehicle, and provide power and kinetic energy for the electrical equipment of the vehicle. The electrical equipment of the vehicle includes capacitors and electrical appliances.

[0016] A main positive relay K+ is connected in series between the positive electrode of the battery pack and the electrical equipment of the vehicle, and a series circuit is connected in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com