Soy online turbidity detection and control apparatus and method thereof

A control method and turbidity technology, which is applied in the direction of food testing, food preparation, material inspection, etc., can solve the problems of time-consuming and labor-intensive manual sampling inspection procedures, affecting production efficiency and benefits, and prolonging the online waiting time of materials, etc., to achieve Avoid the tediousness of repeated confirmation, save time and cost, and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

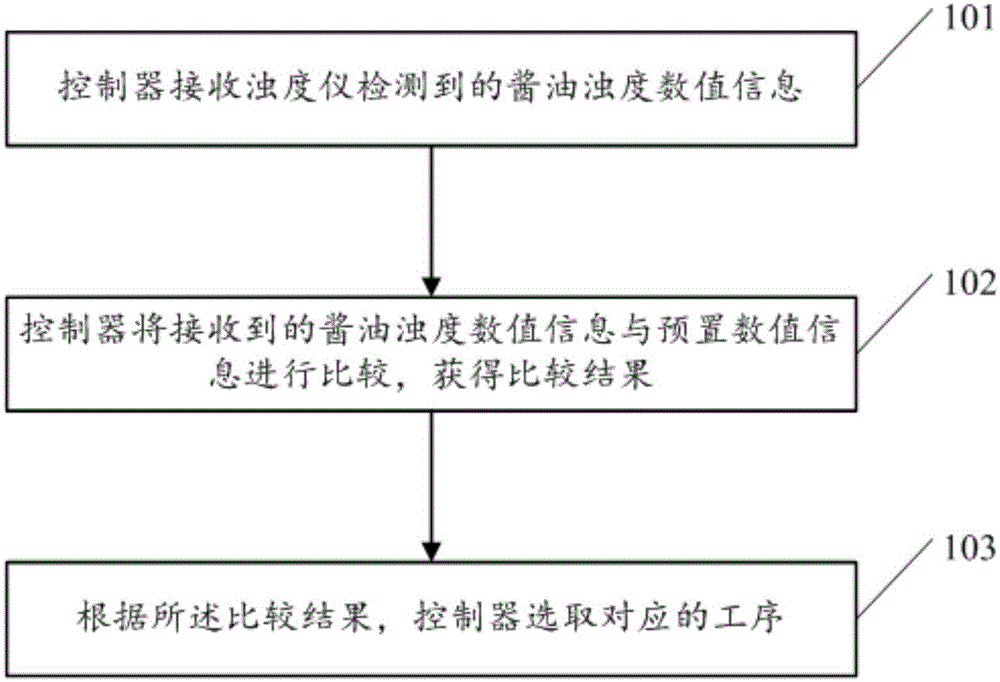

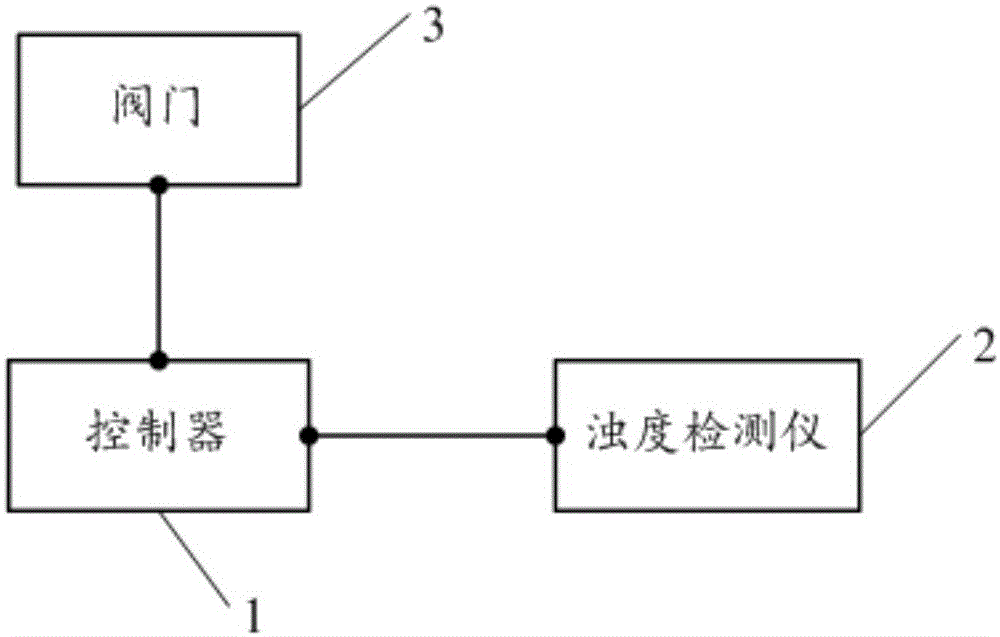

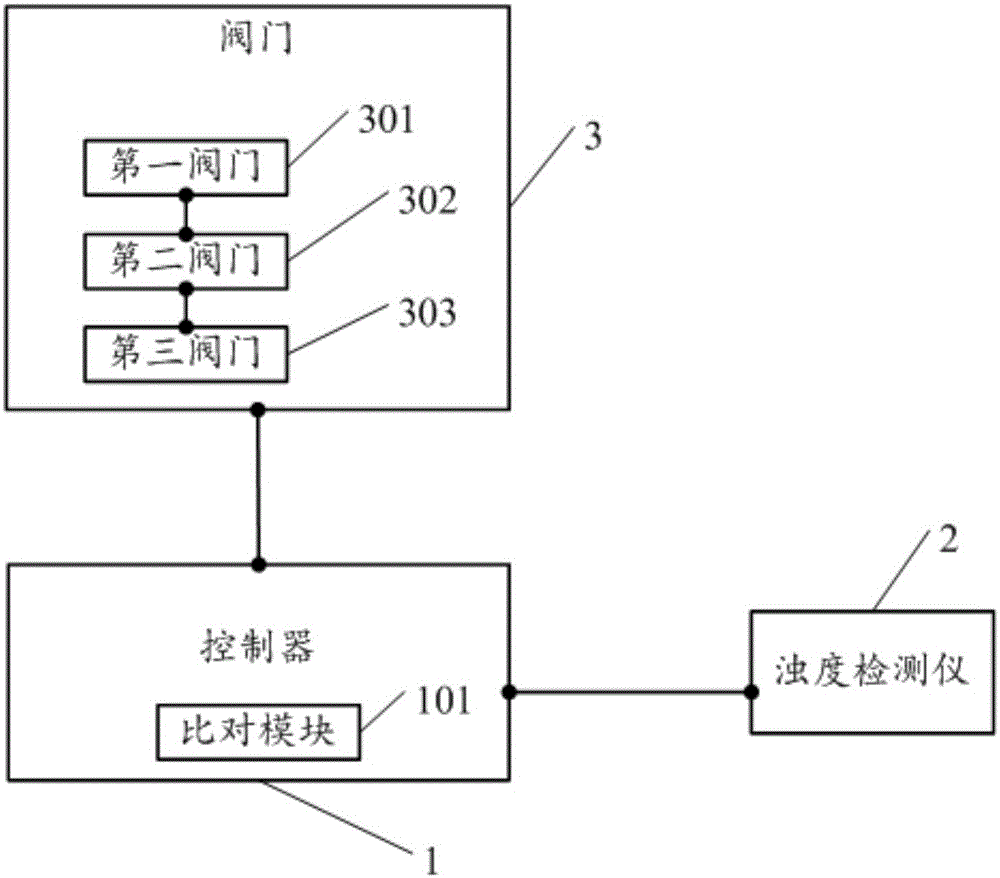

[0027] The embodiment of the present invention provides an online turbidity detection and control method for soy sauce. By using the optical principle, the turbidity detector is used to monitor the material online in real time, which is used to solve the cumbersome manual sampling inspection procedure and avoid the repeated confirmation process , It saves manpower and material resources, shortens the waiting time of materials online, makes the production process uninterrupted, and improves production efficiency.

[0028] In order to make the objectives, features, and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the following The described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com