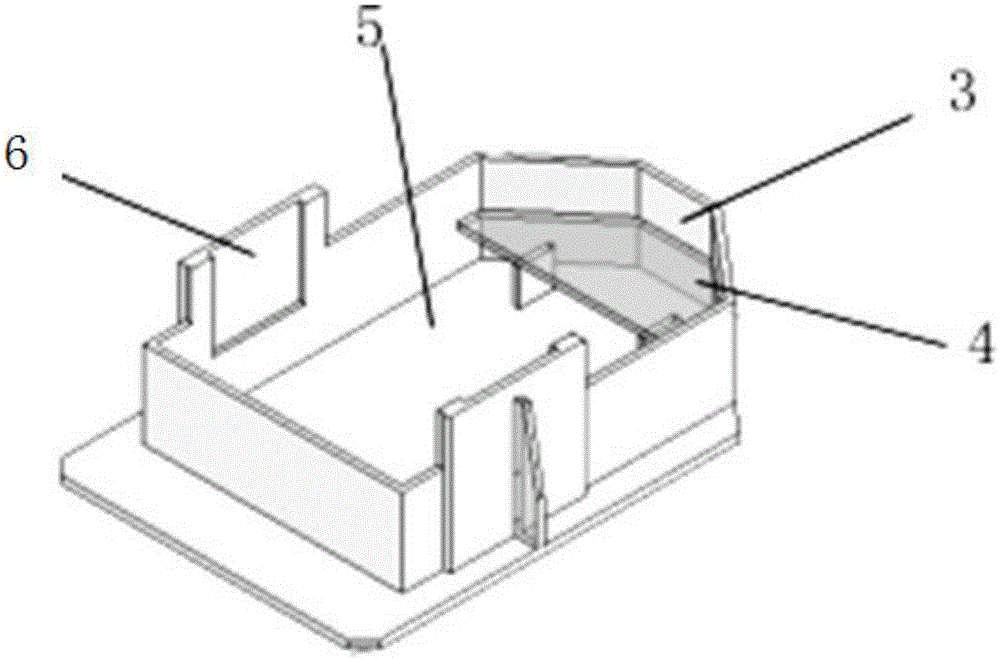

Bituminous mixture permeability testing device and method

A technology of asphalt mixture and testing device, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problems of inability to simulate precipitation intensity and road cross slope, and inability to measure the water volume of asphalt mixture, There are problems such as errors in the measurement results of pavement permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: the evaluation method of OGFC-13 mixture permeability, comprises the steps:

[0034] Select aggregates and SBS asphalt whose gradation is shown in Table 1. It is preliminarily determined that the oil-stone ratio is 4.9%, and the porosity is 18.2%. A rutting plate with a size of 300mm×300mm×50mm is worked out.

[0035] Table 1 OGFC-13 gradation

[0036] Sieve hole(mm)

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Passing rate(%)

98.01

72.94

24.38

16.94

13.35

10.71

8.27

6.82

5.02

[0037] The formula of rainstorm intensity in Nanjing is:

[0038] q = 10716.7 ( 1 + 0.837 lg P ) ( t + 32.90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com