Method for batch measurement of flatness ratio of coarse aggregate

A coarse aggregate and flat rate technology, applied in the field of batch testing of coarse aggregate flatness, can solve problems such as nonconformity and low efficiency, and achieve the effects of convenient operation, simple equipment and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

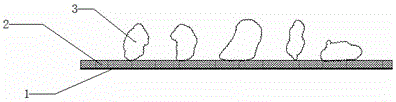

[0026] Such as figure 1 , 2 As shown, a method for measuring the flatness of coarse aggregate includes the following steps:

[0027] Step 1. Select multiple coarse aggregates 3, wash off the dirt on the surface and dry them;

[0028] Step 2. Lay a piece of paper 1 on the horizontal platform, and evenly spread a layer of white plasticine 2 on the paper 1;

[0029] Step 3, evenly discharging the plurality of coarse aggregates 3 treated in step 1 on the plasticine 2, ensuring that the coarse aggregate 3 can stand on the plasticine 2 at any angle;

[0030] Step 4. Use a digital camera to take photos of aggregate 3 directly above the water platform;

[0031] Step 5, input the photograph taken in the computer software Image-Proplus6.0, calculate the ratio of the long and short axes of each coarse aggregate 3;

[0032] Step 6. Flip each aggregate 3, the angle of each flip is different, repeat steps 4 and 5 ten times;

[0033] Step 7. According to step 6, select the maximum long-...

Embodiment 2

[0036] In this embodiment, 30 coarse aggregates were selected, and the flatness rate of each aggregate was measured and the content of needle-like particles was counted.

[0037] Arrange 30 coarse aggregates in 5 rows and 6 columns, and arrange them neatly on the plasticine, with an interval of 0.5cm-1cm between the aggregates, and the aggregates cannot cross the edge of the plasticine. The specific amount of aggregate in other measurements depends on the area of the plasticine and the size of the aggregate.

[0038] Input all the photos taken into the software Image-Proplus6.0 and use the Count / Size function to calculate the ratio of the long and short axes.

[0039] In this example, the maximum flat rate of the 30 particles is 2.669, and the minimum flat rate is 1.103. Among them, 11 particles have a flat rate exceeding 2. According to the specification, it can be known that the above 30 aggregates are not needle-shaped particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com