A fully flexible resistive touch pressure sensor and its manufacturing method

A tactile perception and sensor technology, applied in the field of sensing, can solve the problems of insufficient stress detection sensitivity and accuracy, and achieve the effect of improving surface adaptability, ensuring accuracy and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

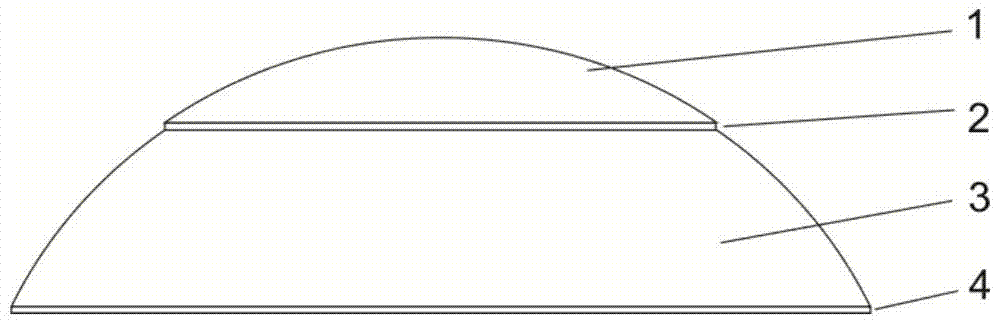

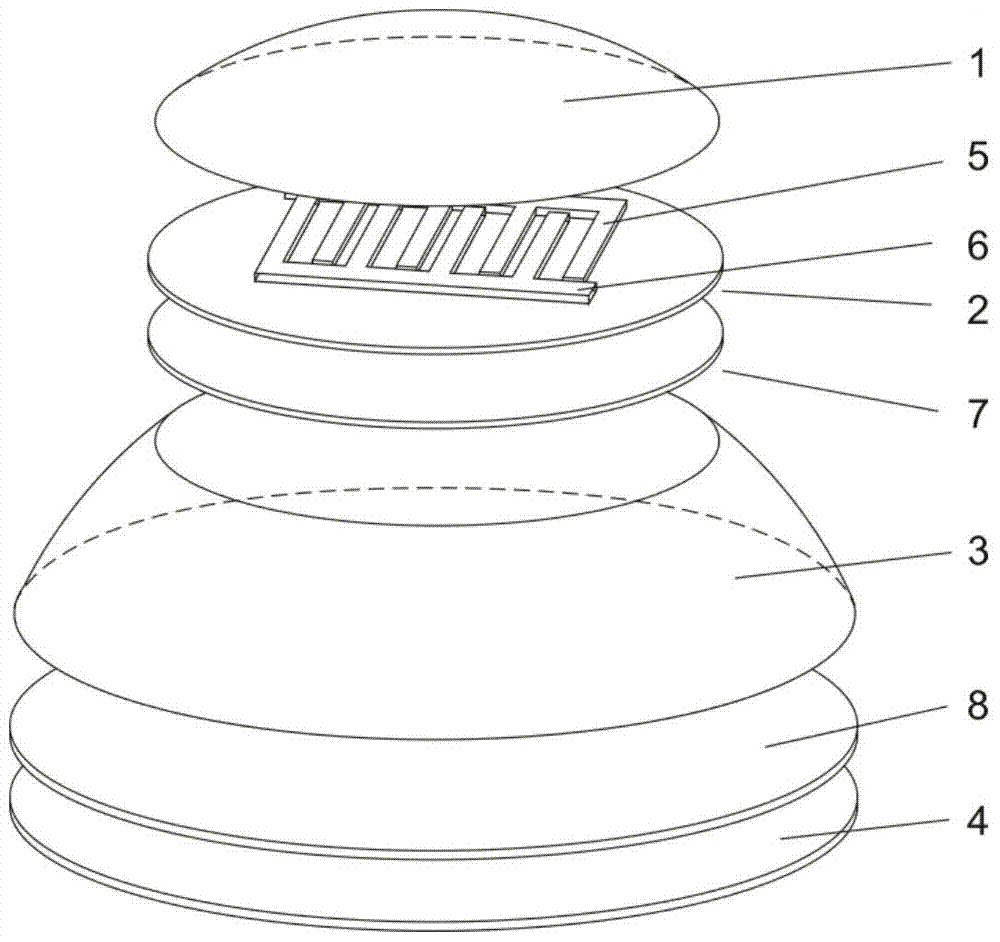

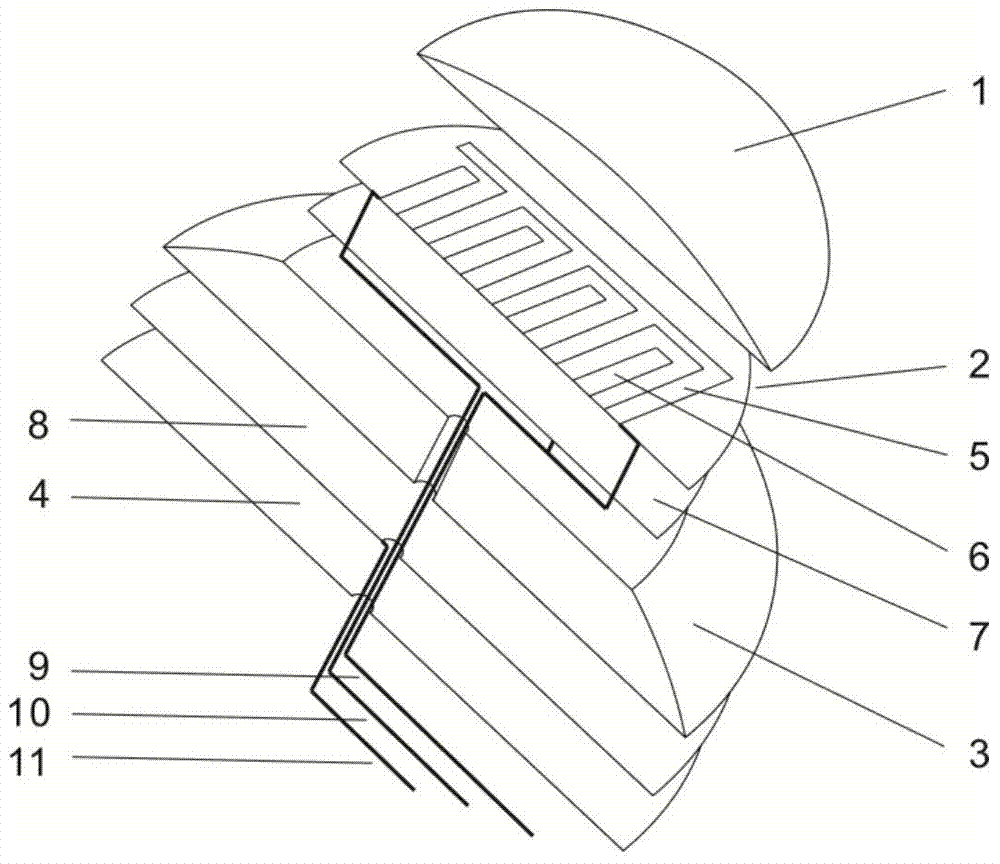

[0032] like figure 1 and figure 2 As shown, the overall structure of the fully flexible resistive touch-pressure sensing sensor of this embodiment is flat hemispherical, which is convenient for all parts of the sensor to feel the external force evenly. The height is 5mm, the bottom radius is 10mm, and the curvature radius is 12.5mm; The tactile sensing sensor for sensing the external force in the small range and the pressure sensing sensor for sensing the external force in the large range in the lower layer;

[0033] The tactile sensing sensor uses graphene / carbon black filled silicone rubber 1 as a sensitive material, adopts an interdigitated electrode structure on the same surface, and the flexible interdigitated electrodes on the upper surface of the upper flexible substrate 2 are used as electrodes;

[0034] The pressure sensing sensor includes carbon nanotubes / carbon black filled silicone rubber 3 as a sensitive material, adopts an upper and lower electrode structure, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com