On-line calibrating device of laser sensing three-dimensional measure system, and calibrating method thereof

A three-dimensional measurement and laser sensing technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as cumbersome operations, and achieve the effects of simple operation, small calculation amount, and increased calculation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in detail:

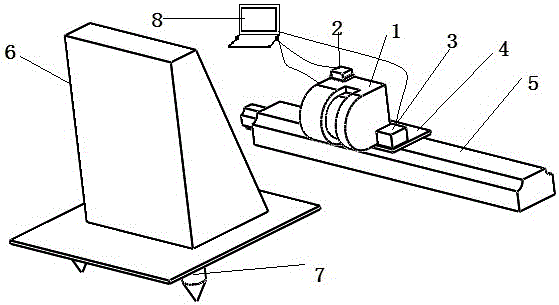

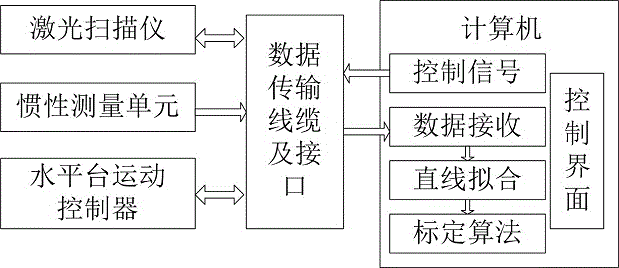

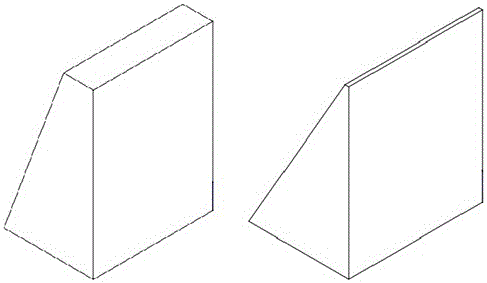

[0018] see figure 1 with figure 2 The online calibration device of the laser sensor three-dimensional measurement system of the present invention comprises a laser scanner 1, an inertial measurement unit 2, a laser ranging sensor 3, a horizontal motion platform 4, a guide rail 5, an adjustable platform 7, two A calibration board 6 with different structural parameters and a computer 8, the inertial measurement unit 2 is installed on the laser scanner 1, and the laser scanner 1 and the laser ranging sensor 3 are all installed on the horizontal motion platform 4; the horizontal motion platform 4 along The guide rail 5 moves linearly, and at the same time controls the adjustable platform 7 to the level with the help of a spirit level, and the calibration plate 6 is placed on the adjustable platform 7 as required. The schematic diagram of a group of two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com