Construction Technology of Frozen Shaft and Wall in Soft Rock Formation

A construction process and technology of freezing wells, which are applied in wellbore lining, well sinking, and shaft equipment, etc., can solve the problems of inability to construct, increase the thickness of the well wall, and increase the construction cost, so as to reduce the construction cost, reduce the thickness of the inner wall, reduce the The effect of saving concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

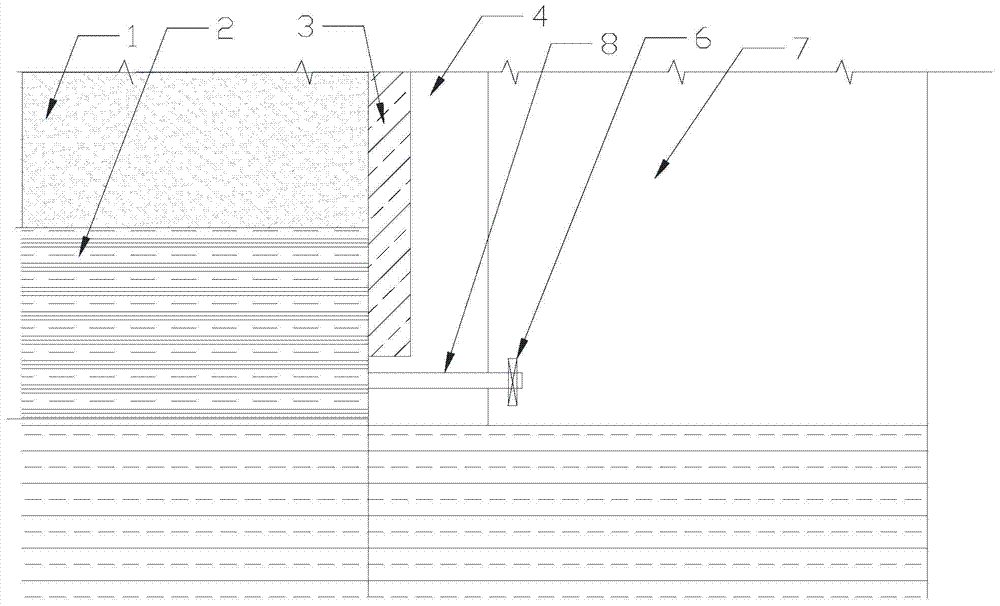

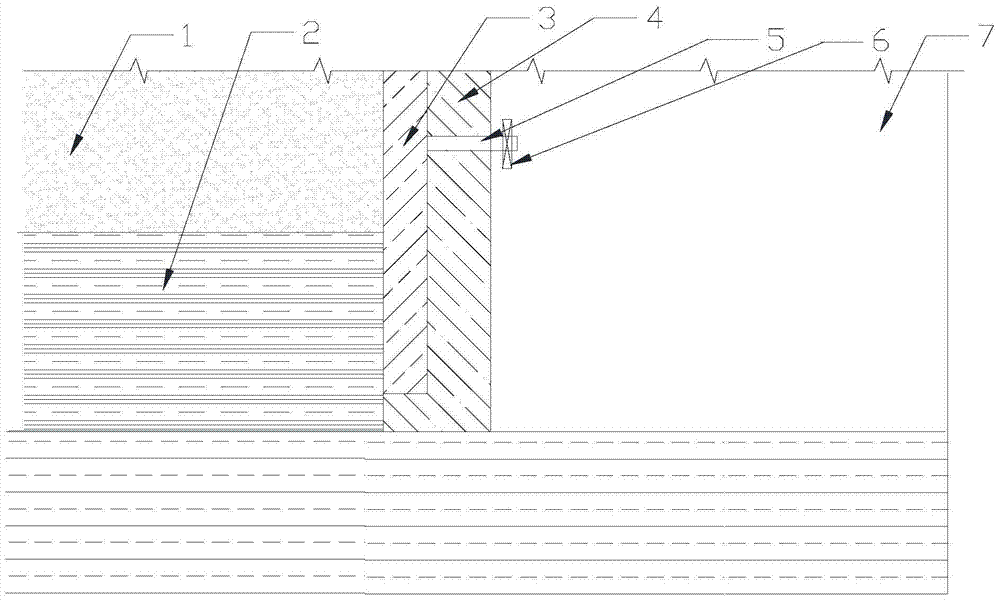

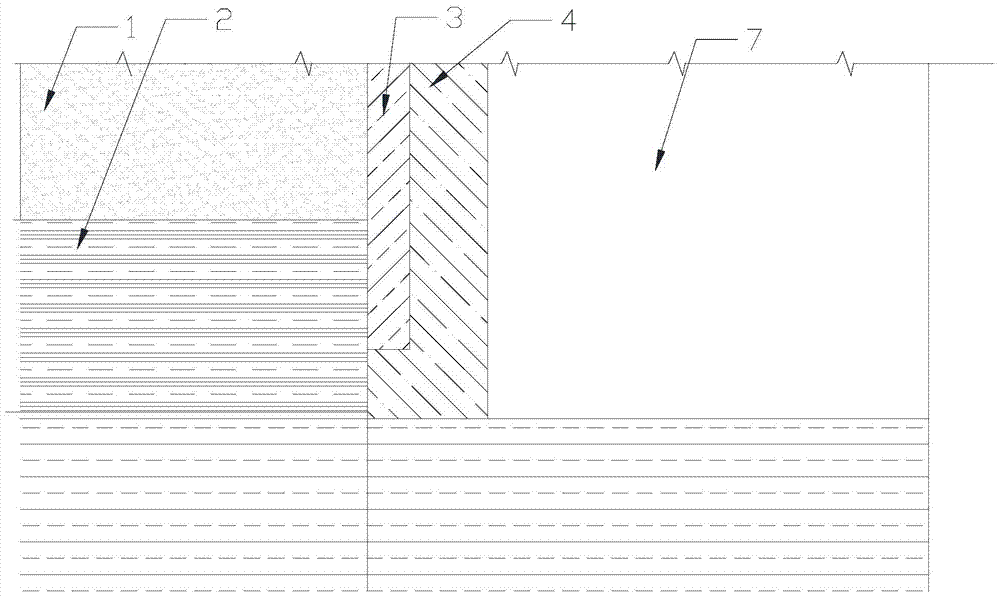

[0034] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0035] like Figure 1~3 Shown, adopt the present invention to carry out construction to the freezing wellbore well wall of soft rock stratum area, comprise the steps:

[0036] (1) Research and analyze the geological data provided by the geological and design departments, determine the distribution of geological layers such as aquifer 1 and water-resisting layer 2 in the formation, and the properties of each geological layer, and form a research on the properties of the formation according to the depth of the frozen section of the wellbore Report, the properties of each stratum should be explained in detail in the research report to meet the needs of well wall design. According to the above research report, the construction personnel will design the frozen wellbore well wall in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com