Processing device and method for reinforcing bearing steel balls

A technology for strengthening treatment and bearing steel balls, which is applied in ion implantation plating, metal material coating process, coating and other directions, and can solve problems such as lack of rapid development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

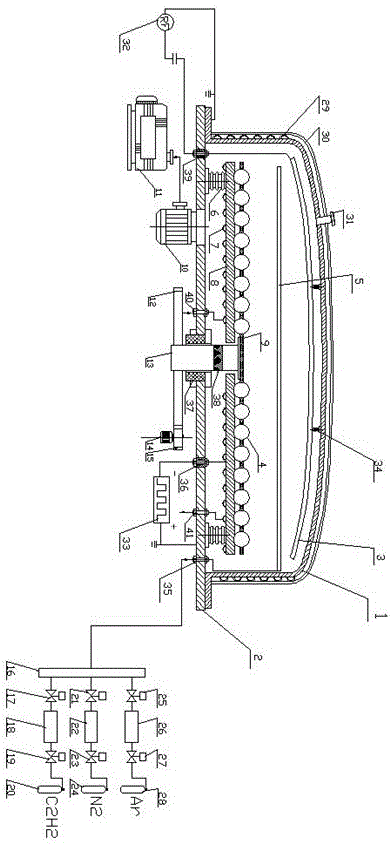

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] A bearing steel ball strengthening treatment device includes a vacuum treatment chamber, a rotating mechanism, a transmission mechanism, a high-voltage target platform, a plasma generator, a high-power high-voltage pulse power supply, a gas supply system, and a high-vacuum pumping system. The vacuum processing chamber includes a bell jar 1 and a base plate 2 , and the bell jar 1 is placed above the base plate 2 . The high-voltage target platform includes a target platform disc 8 and an insulating support 6. One end of the insulating support 6 is fixed on the base plate 2, and the other end is fixed on the bottom 8 of the target platform disc to support and fix it. The rotating mechanism includes a transmission shaft 13 and a dial 9; one end of the transmission shaft 13 passes through the target disc 8 and connects to the dial 9, and the other end of the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com