PET foam product and preparation method thereof

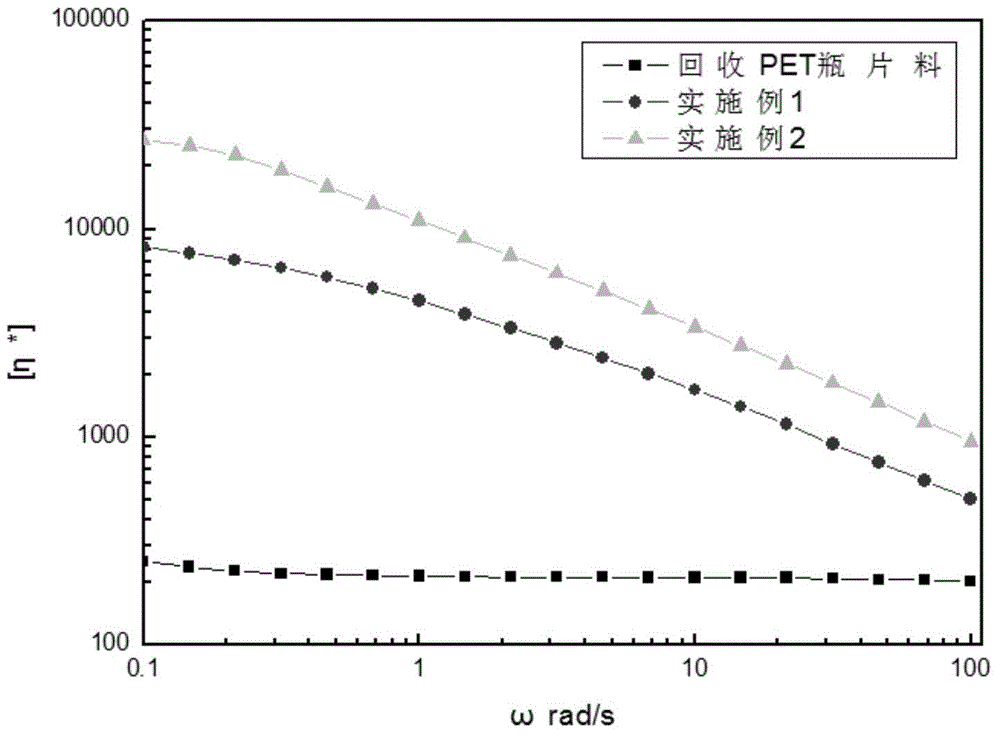

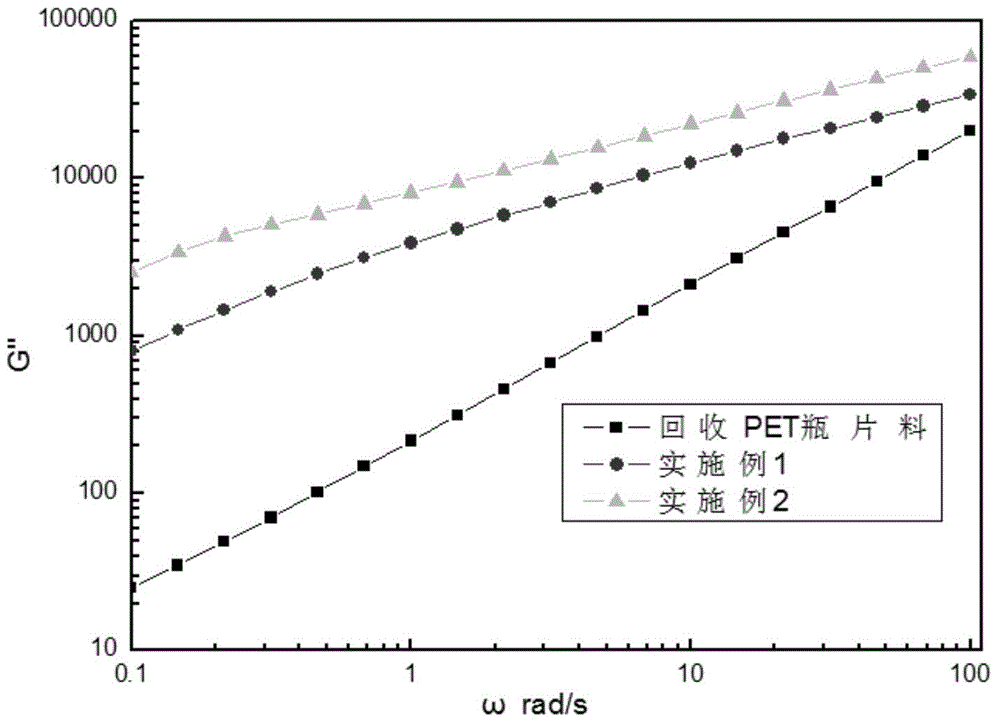

A foaming product and raw material technology, applied in the field of polyester foaming products, can solve the problems of PET polyester such as low molecular weight, difficulty in normal foaming, poor melt strength, etc., to achieve improved melt strength, low equipment requirements, foaming The effect of uniform hole size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of PET foam product, it comprises the steps:

[0041] 1. Dry the discarded PET bottle flakes in a blast oven at 100°C for 13 hours, and then transfer them to a vacuum oven at 135°C for 14 hours in vacuum to obtain physically recycled PET bottle flakes;

[0042] 2. Weigh 4kg physically recycled PET bottle flakes, 12gTGIC, 4gPMDA, 4g antioxidant 1010, 4gTPP, mix them evenly and put them into the twin-screw extruder to extrude and granulate; control the temperature of each section of the twin-screw extruder in: Zone 1 260°C, 260°C in the second zone, 265°C in the third zone, 265°C in the fourth zone, 260°C in the fifth zone, and 260°C in the sixth zone; the rotation frequency of the feeder of the twin-screw extruder is 15hz, and the rotation frequency of the host is 13.5hz;

[0043] 3. After drying the extruded pellets in a blast oven and a vacuum oven at 120°C for 12h, take them out for solid-state polycondensation, wherein the reaction temper...

Embodiment 2

[0046] A kind of preparation method of PET foam product, it comprises the steps:

[0047] 1. Dry the discarded PET bottle flakes in a blast oven at 110°C for 12 hours, and then transfer them to a vacuum oven for 12 hours at 140°C to obtain physically recycled PET bottle flakes;

[0048] 2. Weigh 2kg physically recycled PET bottle flakes, 8gTGIC, 2gPMDA, 2g antioxidant 1010, 2gTPP, mix them evenly and put them into the twin-screw extruder to extrude and granulate; control the temperature of each section of the twin-screw extruder in: Zone 1 255°C, 255°C in the second zone, 255°C in the third zone, 265°C in the fourth zone, 265°C in the fifth zone, and 265°C in the sixth zone; the rotation frequency of the feeder of the twin-screw extruder is 15hz, and the rotation frequency of the host is 13.5hz;

[0049] 3. Dry the extruded pellets in a blast oven and a vacuum oven at 100°C for 15 hours, then take them out for solid-state polycondensation. The reaction temperature is 220°C, th...

Embodiment 3

[0052] A kind of preparation method of PET foam product, it comprises the steps:

[0053] 1. Dry the discarded PET bottle flakes in a blast oven at 110°C for 12 hours, and then transfer them to a vacuum oven for 12 hours at 140°C to obtain physically recycled PET bottle flakes;

[0054] 2. Weigh 2kg physically recovered PET bottle flakes, 6gTGIC, 1gADR4730, 2g antioxidant 168, 3gTEPA, mix them evenly and put them into the twin-screw extruder for extrusion and granulation; control the temperature of each section of the twin-screw extruder in: Zone 1 260°C, 265°C in the second zone, 270°C in the third zone, 265°C in the fourth zone, 260°C in the fifth zone, and 260°C in the sixth zone; the rotation frequency of the feeder of the twin-screw extruder is 15hz, and the rotation frequency of the host is 13.5hz;

[0055] 3. After drying the extruded pellets in a blast oven and a vacuum oven at 110°C for 12 hours, take them out for solid-state polycondensation, wherein the reaction tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com