A method for controlling the surface wettability of polychlorinated p-xylylene film by surface patterning

A technology of p-xylene and surface patterns, applied in the direction of coating, etc., can solve problems such as degradation, and achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The PC film was ultrasonically cleaned with acetone and ethanol for 10 minutes, then dried at 50°C for 90 minutes, then pretreated with air plasma at 100V for 10s, then spin-coated with 1wt% PAA aqueous solution at 3000rpm for 30s, and then dried at 50°C for 90 minutes, and then the pore area was 10%. , a circular hole mask with a hole center spacing of 280 μm is placed on the above PC film, and then directly UV / O 3 After treatment for 300s, wash with water for 30 minutes, then dry at 50°C for 90 minutes, and test the surface water droplet contact angle and transparency.

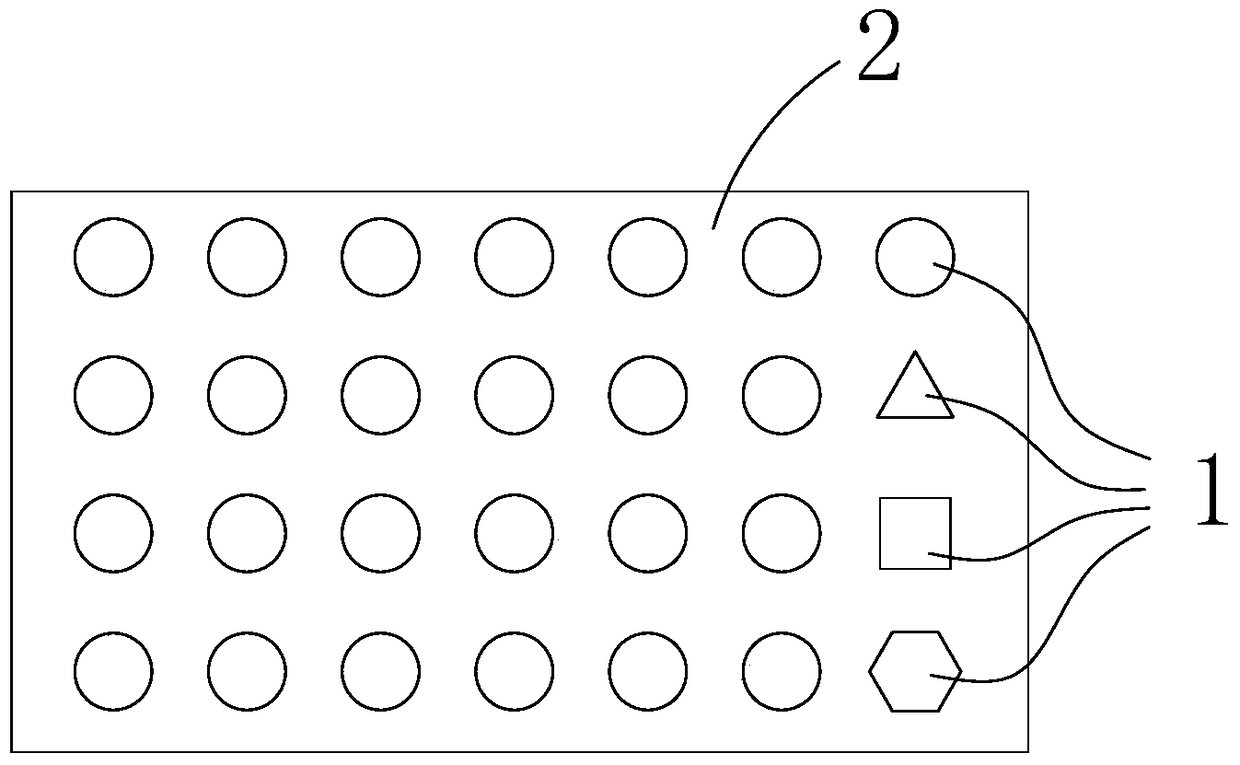

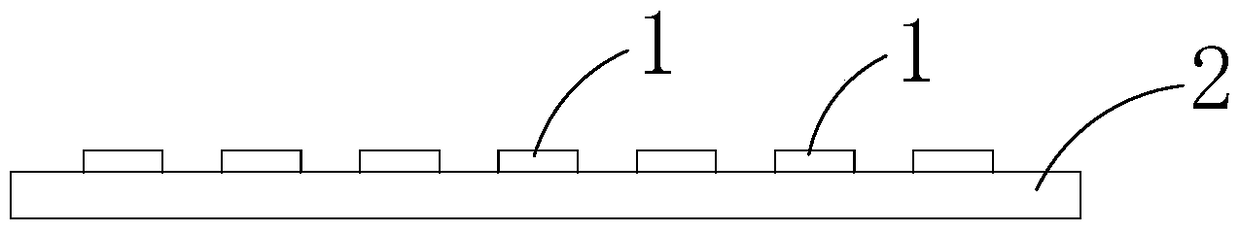

[0050] The structure of the patterned PC film is as figure 2 (top view), image 3 (side view). Under the masking effect of the mask plate with holes on the surface, there are a large number of hydrophilic patterns on the surface of the PC film after light crosslinking (preferably evenly distributed, figure 2 is an example of uniform distribution), these hydrophilic patterns have a significant eff...

Embodiment 2

[0054] The PC membrane was ultrasonically cleaned with acetone and ethanol for 10 minutes, dried at 50°C for 90 minutes, pretreated with air plasma at 100V for 10s, then spin-coated with 1wt% PAA aqueous solution at 3000rpm for 30s, dried at 50°C for 90mins, and then coated with a pore area of 20%. , a circular hole mask with a hole center spacing of 198 μm is placed on the above PC film, and then directly UV / O 3 After treatment for 300s, wash with water for 30 minutes, then dry at 50°C for 90 minutes, and test the surface water droplet contact angle and transparency.

Embodiment 3

[0056] The PC film was ultrasonically cleaned with acetone and ethanol for 10 minutes, dried at 50°C for 90 minutes, pretreated with air plasma at 100V for 10s, then spin-coated with 1wt% PAA aqueous solution at 3000rpm for 30s, dried at 50°C for 90mins, and then the pore area was 30%. , a circular hole mask with a hole center spacing of 162 μm is placed on the above PC film, and then directly UV / O 3 After treatment for 300s, wash with water for 30 minutes, then dry at 50°C for 90 minutes, and test the surface water droplet contact angle and transparency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com