High-speed and heavy-duty rubber belt-type track section and track made by track sections

A rubber belt and crawler technology, applied in the field of high-speed heavy-duty crawler vehicles, can solve the problems of ineffective lightweight and high efficiency, and achieve the effect of improving survivability and combat performance, reducing bending stiffness and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

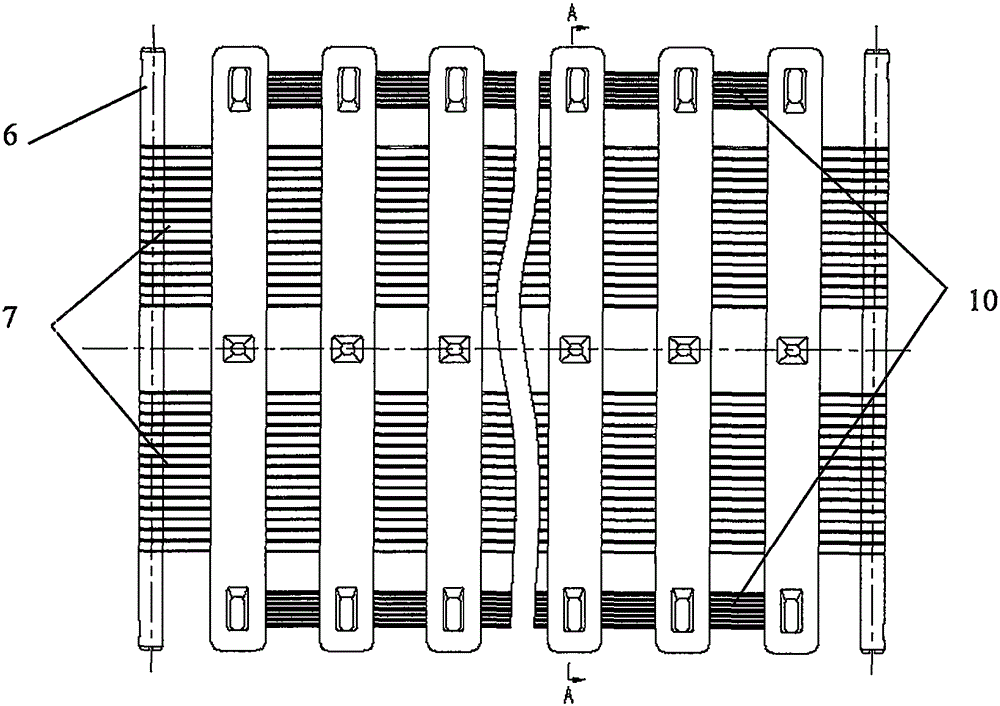

[0015] Such as Figure 1-5 As shown, the present invention is a high-speed heavy-duty rubber belt crawler section, including a traction frame and a supporting frame. The supporting frame is composed of a plurality of unit bodies arranged intermittently. The shape is the same, and the traction frame is composed of crawler pins 6 at both ends, two steel cords 7 wound between the crawler pins 6 at both ends, and aramid fiber wires 10 located outside the steel cords 7. At the end, as the bridge for the main track section to transmit force, two sections of steel wire curtain 7 divide the track pin 6 into three sections, the two ends of the track pin 6 are used to install the end coupler 5, and the middle section is used to install the intermediate coupler 4, The unit body supporting the skeleton is composed of an upper part 8 and a lower part 9, both of which are integrally formed by polymer materials located on the outside and metal inside. 7. The aramid thread 10 is fixed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com