Three-freedom-degree transfer robot with movable support

A technology for handling robots and moving supports, applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of difficulty in guaranteeing position and attitude accuracy, high manufacturing cost of five-axis robots, and narrowing the scope of working space of the mechanism. The process is simple and lightweight, the structure is simple, and the inertia is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

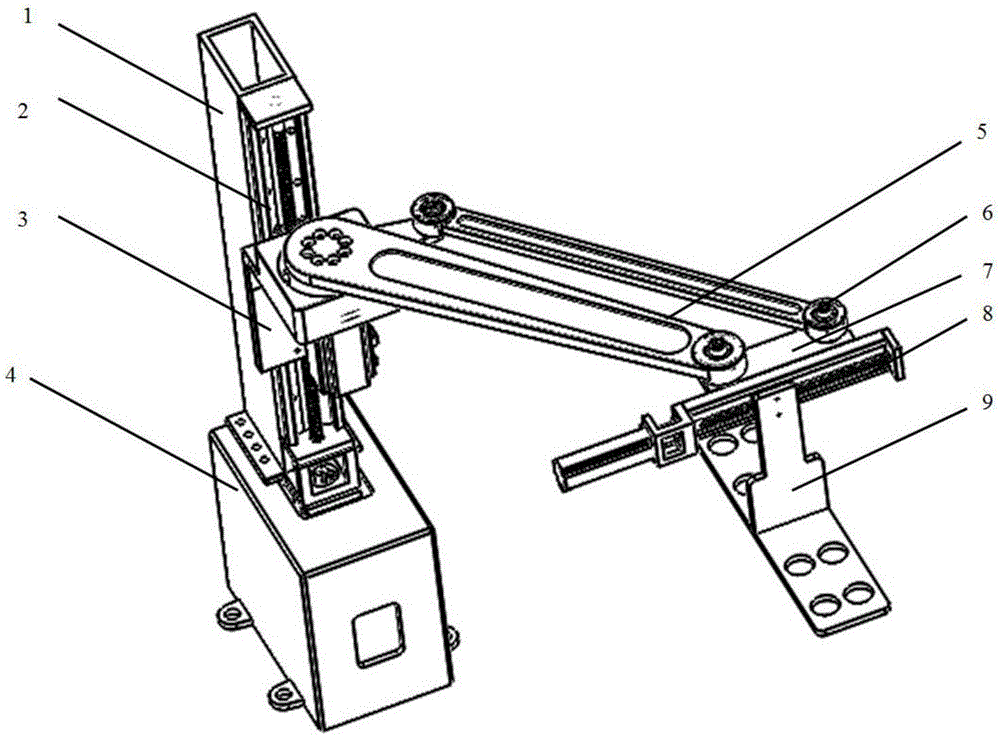

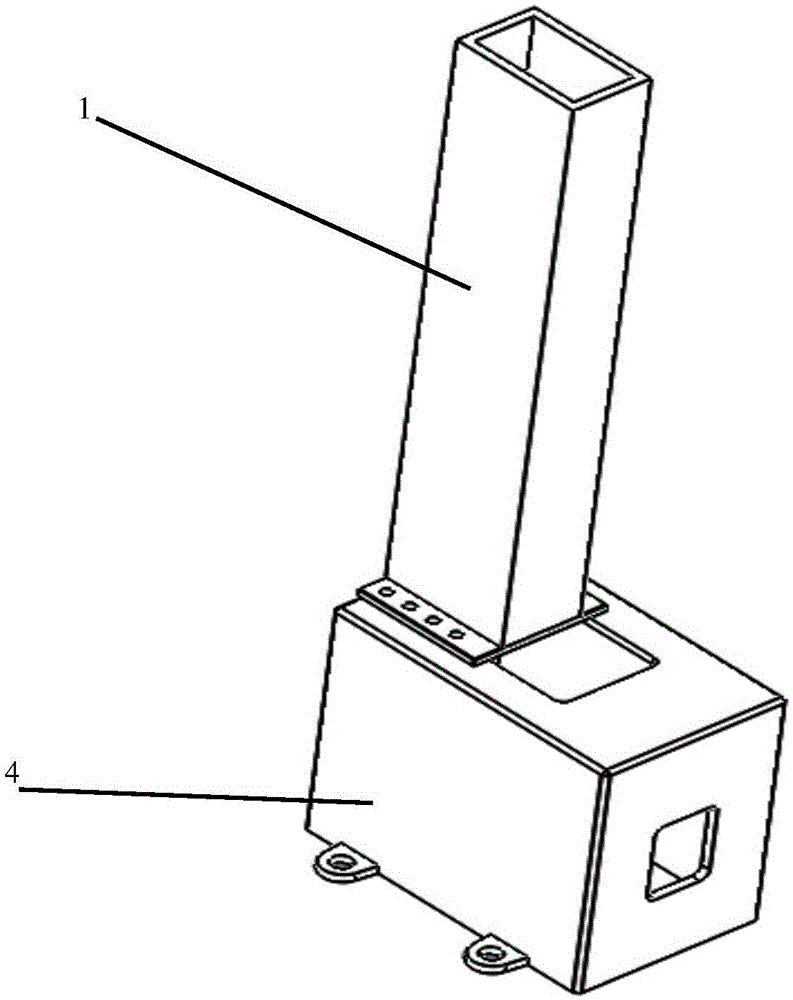

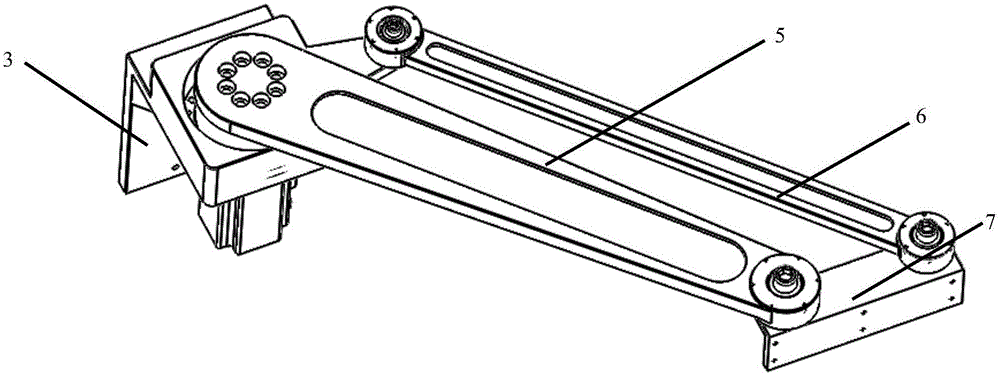

[0023] A moving support three-degree-of-freedom handling robot provided by the present invention includes a rectangular hollow column 1, a first linear module 2, a moving support 3, a base 4, an active arm 5, an attitude maintaining bar 6, an end mounting plate 7, a second A linear module 8 , a suction cup mounting plate 9 , a first driving mechanism 10 , a second driving mechanism 11 and a third driving mechanism 12 . The hollow column 1 and the base 4 jointly form a frame; the movable bracket 3, the active arm 5, the posture-keeping rod 6, and the end mounting plate 7 jointly form an arm delivery device; the end effector includes a second linear module 8 And the suction cup mounting plate 9; wherein the first drive device 10 is used to drive the first linear module 2, the second drive device 11 is used to drive the arm delivery device, and the third drive device 12 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com