Coaxial electrolyte flushing method and device for array group electrode micro-hole electromachining

A group electrode and electrical machining technology, which is applied to the field of coaxial flushing of micro-holes of array group electrodes, can solve the problems of different flow rates and poor consistency of group hole sizes, and achieves the effects of improving stability, convenient operation, and simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

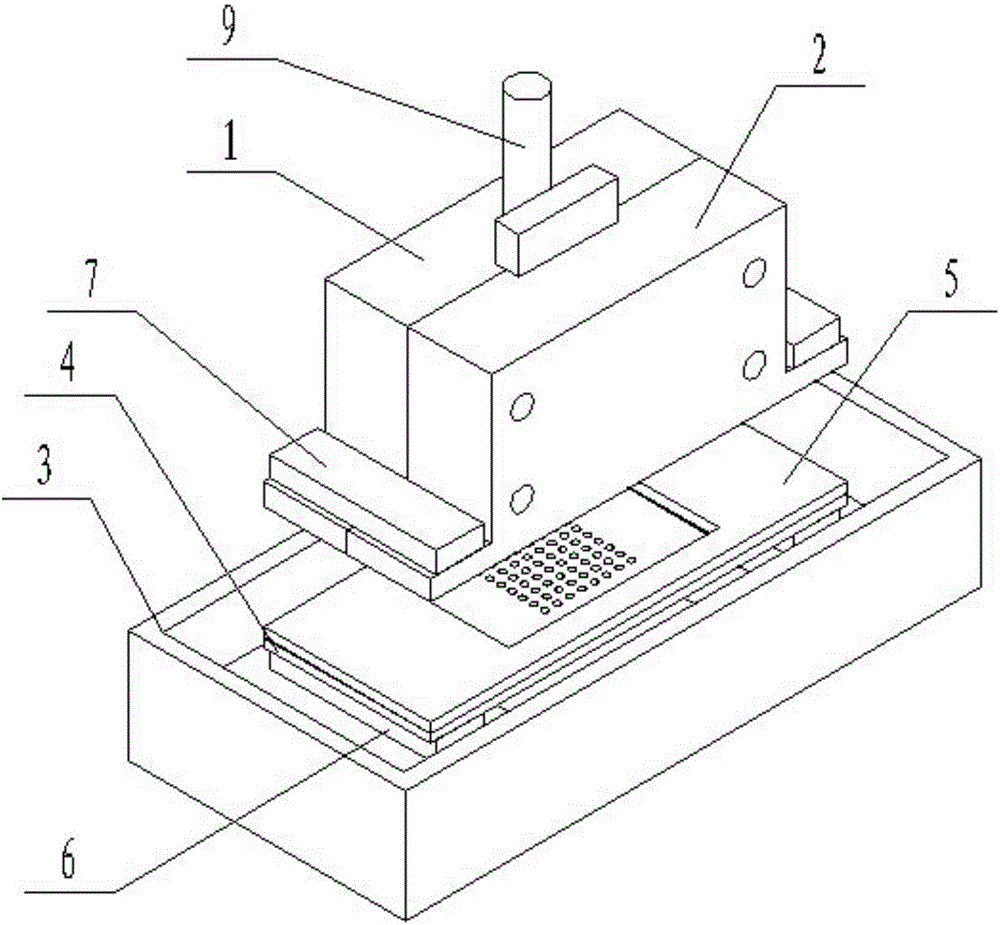

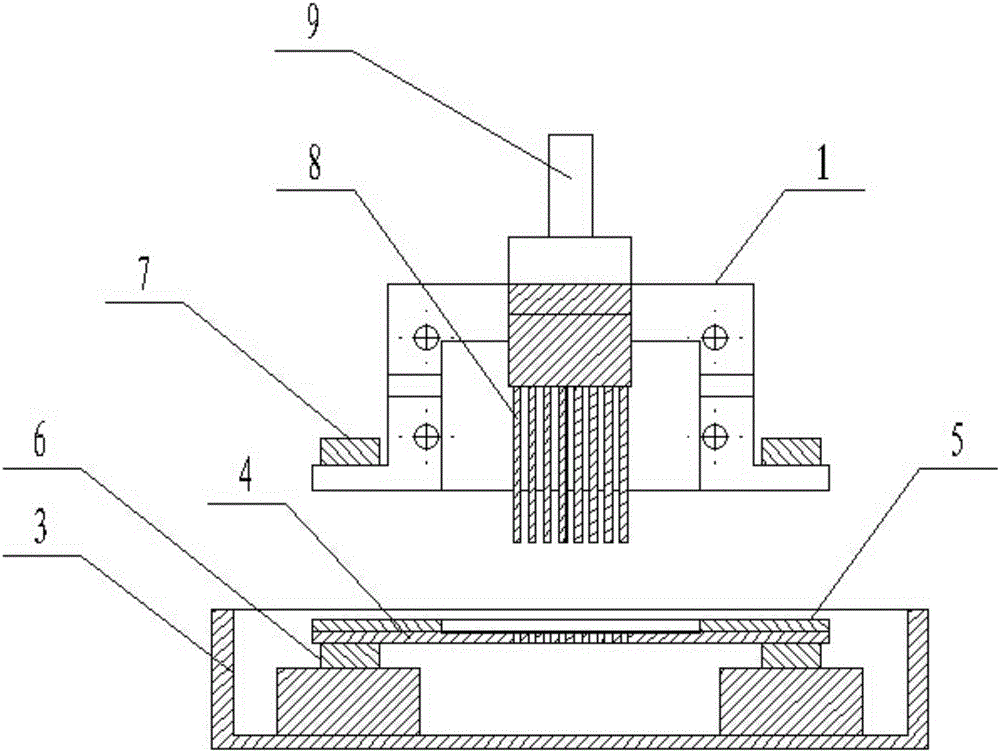

[0021] Such as Figure 1~2 As shown, a coaxial liquid flushing device for electromachining tiny holes of an array group electrode includes an array group electrode 8, an electrolyte sealing cavity, an electrolyte tank 3, an insulating gasket 5, an upper electromagnetic chuck 7 and a lower electromagnetic chuck 6, and the array The cathode end of the group electrode 8 is provided with a plurality of single cathodes distributed in an array, the array group electrode 8 is clamped through the electrolyte sealed cavity, the cathode end of the array group electrode 8 is vertically downward, and the array group electrode 8 is set directly below The workpiece 4 to be processed is fixed with a lower electromagnetic chuck 6 on both sides of the bottom of the workpiece 4 to be processed, an insulating gasket 5 is arranged on the upper end of the workpiece 4 to be processed, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com