Purification method and device for variable-reluctance transducer

A magnetoresistive sensor and sensor technology, applied in the electrical field, can solve the problems of increasing maintenance costs, measuring operation errors, etc., and achieve the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

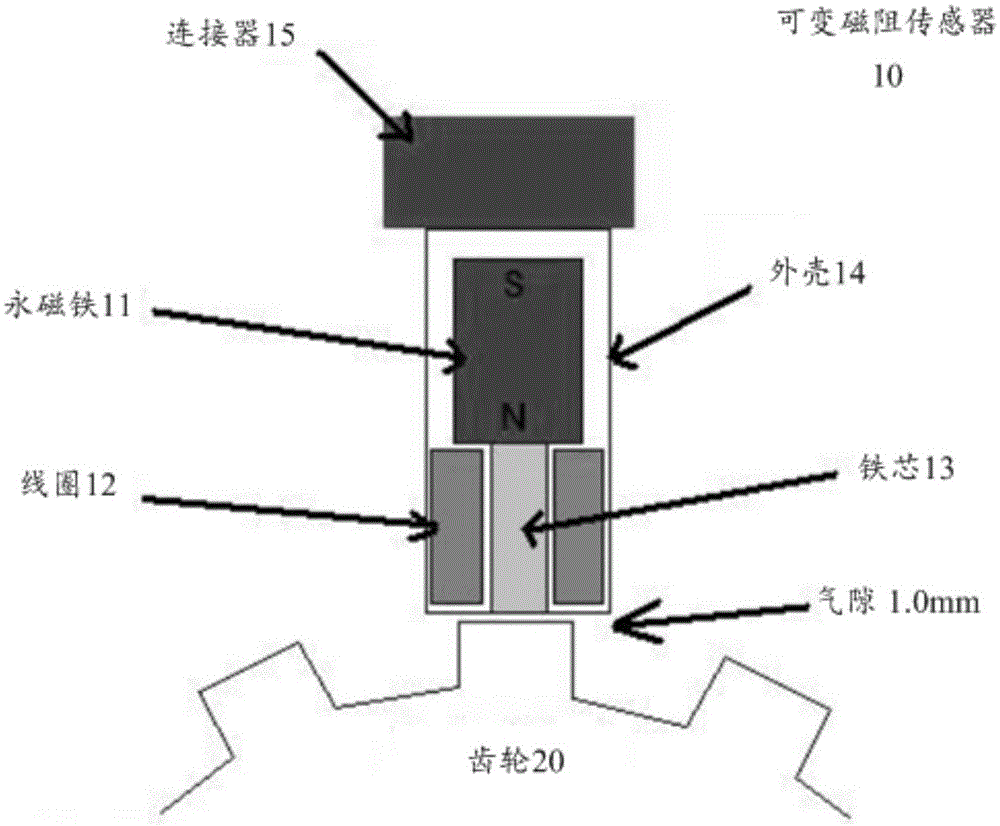

[0038] Various embodiments according to the present invention will be described in detail with reference to the accompanying drawings. Here, it is to be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same or similar structures and functions, and repeated descriptions about them will be omitted.

[0039] First, the basic structure of a variable reluctance sensor (VRS) will be briefly described in a specific example for a better understanding of the embodiments of the present invention. In this specific example, the variable reluctance sensor may be a sensor commonly equipped in combustion and compression engines to detect crankshaft speed. This sensor is usually called a crankshaft position sensor (CPS). CPS is one of the most important sensors in an engine. one.

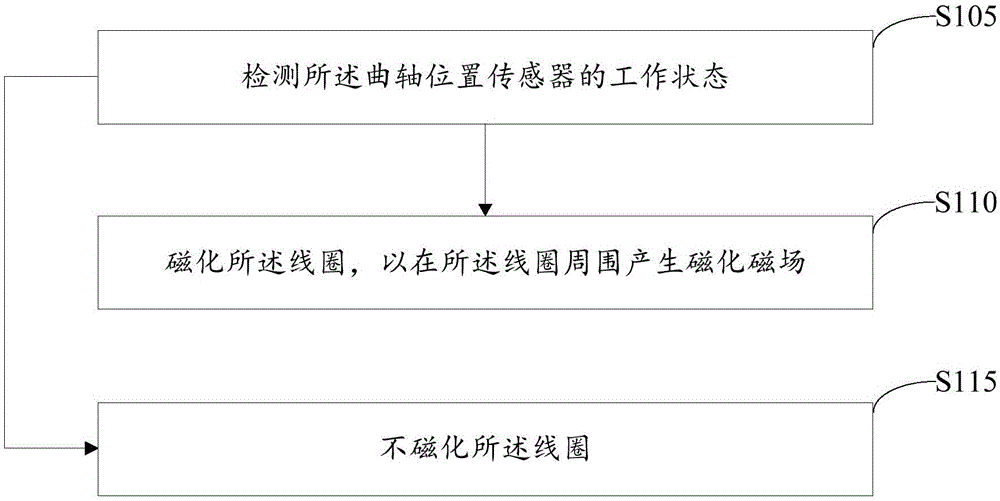

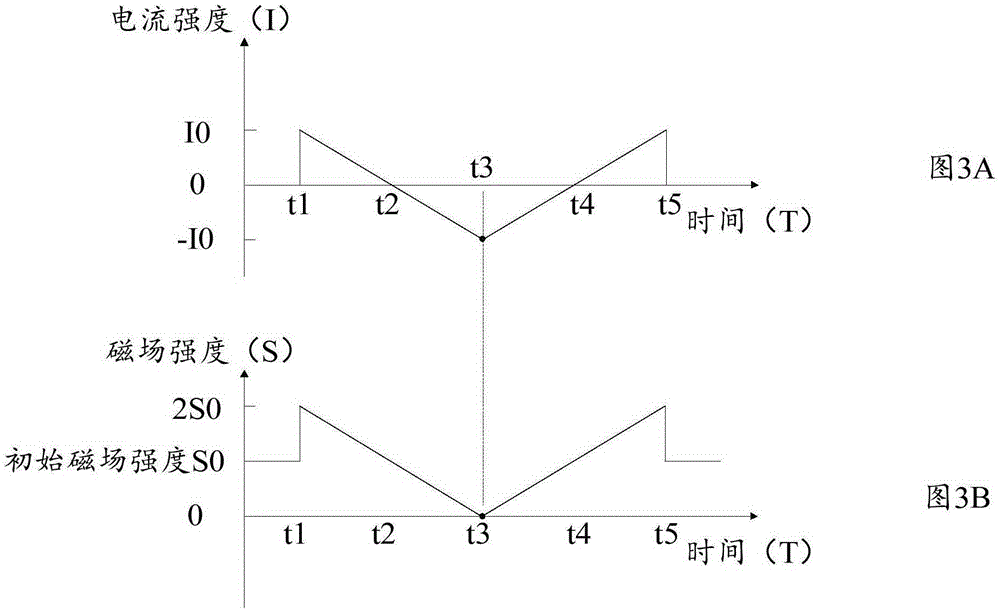

[0040] figure 1 The basic structure of a specific example of the variable reluctance sensor according to the embodiment of the present invention is illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com