Method for preparing high-anti-fatigue-action soybean peptide determined by microcalorimetric method and anti-fatigue action evaluation experiment

A technology of anti-fatigue activity and microcalorimetry, which is applied in the direction of plant protein processing, etc., can solve the problems of inability to accurately and quantitatively determine the optimal process of protease hydrolysis reaction, lack of theoretical guidance for protease hydrolysis process control, and complicated test methods. High fatigue function, good water solubility, and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Preparation of solution:

[0020] Solution ①: Accurately weigh the soybean protein isolate sample, and prepare 10gL of buffer solutions with pH values of 6.70, 7.21, 7.73, 8.21, and 8.73 respectively. -1 soy protein isolate solution.

[0021] Solution ②: The preparation concentration is 0.2gL -1 Trypsin solution.

[0022] 2. The soy protein isolate solution was treated in a water bath at 90°C for 10min;

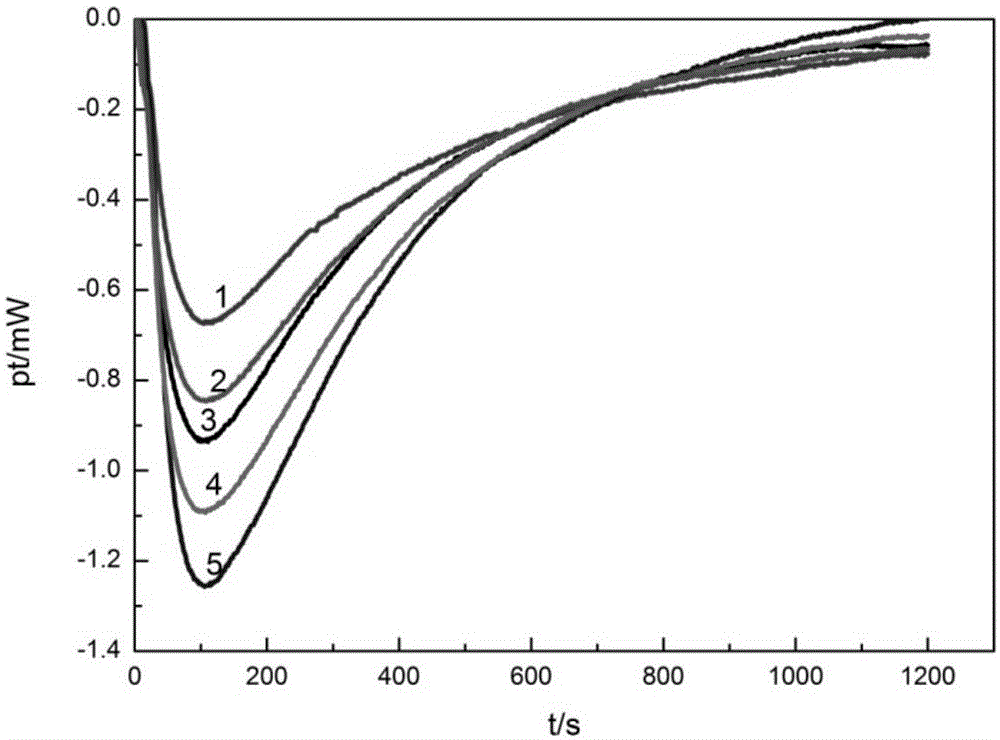

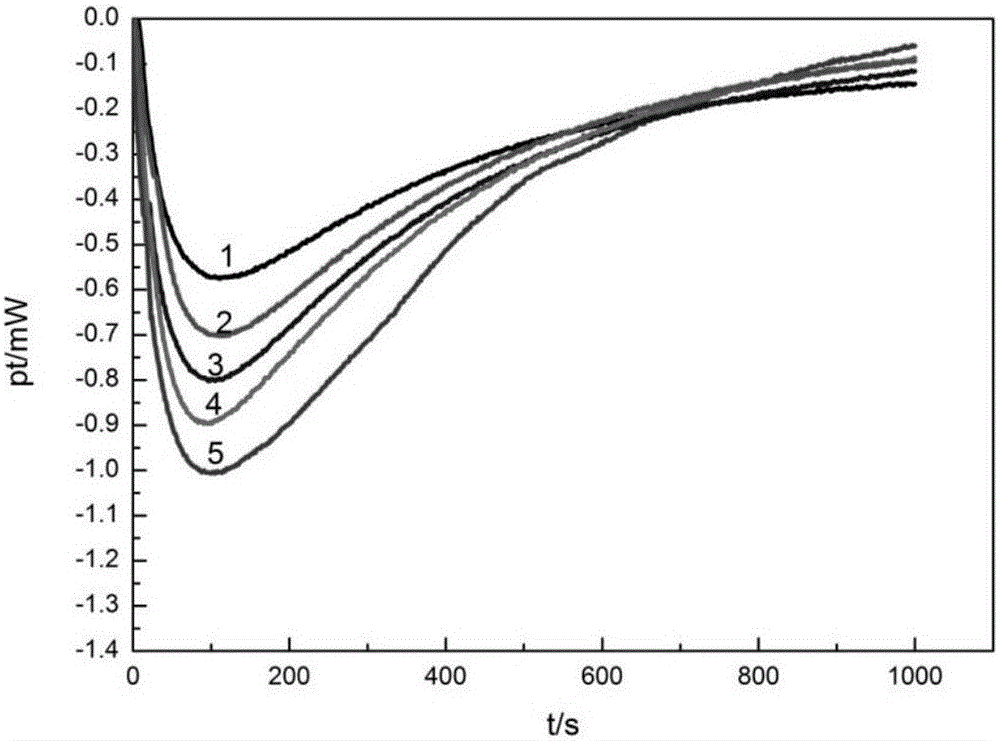

[0023] 3. Experiments were carried out in 4 ml stainless steel ampoules (titration microcalorimeter). Take 2ml of soy protein isolate solution and put it into a stainless steel ampoule. Wind the connecting rod of the titration microcalorimeter around a thin plastic tube, and the tube contains 1ml of alkaline protease solution. The stirring system was turned off, and the rotating speed was 120 rpm. The trypsin solution was injected into the ampoule with a peristaltic pump, and then the thermal power-time curve was measured. stop. The experiment was repeated ...

Embodiment 2

[0032] 1. Sizing

[0033] Put the protein isolate into a temperature-controlled enzyme reactor tank with a stirrer, add water to adjust the slurry, and the slurry concentration is about 10%;

[0034] 2. Enzyme reaction

[0035] After sizing, add alkaline microbial protease according to 1% of the weight of the substrate protein, add the enzyme while stirring, add alkali at any time, keep the pH value ≈ 8.25, the stirring speed = 120r / min, and the enzymatic hydrolysis temperature is maintained at about 329.5K , after 3 hours of enzymatic hydrolysis, 1:2 of bromelain with alkaline protease was added, and the optimal reaction temperature of bromelain was 314.63K, and the optimal reaction pH was 6.99 for 1h.

[0036] 3. Separation and extraction

[0037] The mixed solution after enzymolysis is inactivated by enzyme treatment, pH 4.5, to precipitate unenzymolyzed protein, the mixed solution is pumped into a separator for solid-liquid separation, and the effluent is all acid-solubl...

Embodiment 3

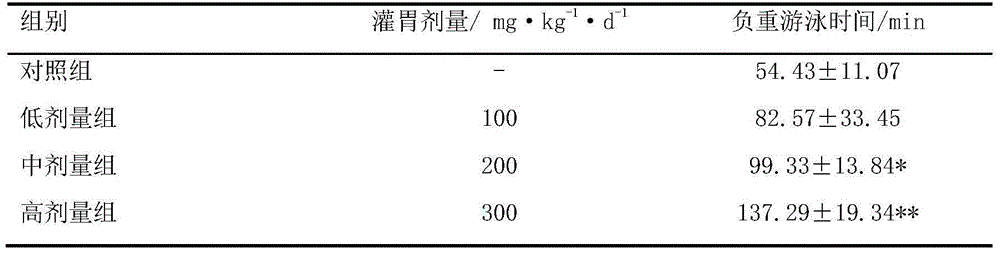

[0047] Anti-fatigue activity evaluation experiment

[0048] Animals: Mice, healthy Kunming species, body weight (25±2) g, all of SPF grade (specific pathogen-free), provided by Taian Taibang Company.

[0049] Tested product: Example 2 product "Soybean peptide with high anti-fatigue activity"

[0050] Animal grouping and administration:

[0051] Pre-test for 3 days, during the pre-test period, the mice were domesticated and observed to observe their adaptation to the new environment, and to train them to feed at fixed points; the daily supply of feed was determined according to the feeding rate table, and the corresponding feeding situation was made. Adjustment. Feeding follows the principles of fixed-point, timed, quantitative and qualitative. Mice whose physique and exercise capacity were significantly different from the average were eliminated. After the pre-test, the mice were randomly divided into 4 groups with 30 mice in each group: the control group, the low, medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com