Method for preparing ice cream by adopting camel milk

A technology of camel milk and ice cream, applied in applications, frozen desserts, food science, etc., to achieve the effect of alleviating heart failure, low fat content, and relieving cough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

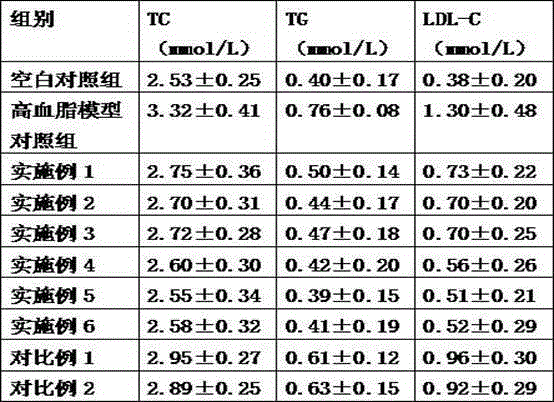

Examples

Embodiment 1

[0029] A method for preparing ice cream by using camel milk, which is composed of the following raw materials in weight ratio: 140 parts of camel milk powder, 140 parts of honey, 120 parts of unsalted butter, 30 parts of cream, 20 parts of eggs, 2 parts of stabilizer, natural essence 1 serving.

[0030] The specific preparation method is:

[0031] (1) Mixing and sterilization

[0032] Mix the above raw materials into the mixing tank, the stirring speed of the mixing tank is 1500 rpm, filter after mixing, and sterilize at 75°C for 25 minutes;

[0033] (2) homogeneous

[0034] After sterilization, use a high-pressure homogenizer for homogenization at a temperature of 70°C, a homogenization pressure of 13Mpa, and a time of 20 minutes;

[0035] (3) cooling

[0036] After homogenization, cool to 0°C with a plate exchanger;

[0037] (4) Aging

[0038] After cooling, enter the aging tank for aging, the temperature is 2°C, and the aging time is 2 hours;

[0039] (5) freezing

...

Embodiment 2

[0044] A method for preparing ice cream by using camel milk, which is composed of the following raw materials in weight ratio: 150 parts of camel milk powder, 145 parts of honey, 130 parts of unsalted butter, 40 parts of cream, 25 parts of eggs, 3 parts of stabilizer, natural flavor 1.5 servings.

[0045] The specific preparation method is:

[0046] (1) Mixing and sterilization

[0047] Mix the above raw materials into the mixing tank, the stirring speed of the mixing tank is 1500 rpm, filter after mixing, and sterilize at 78°C for 27 minutes;

[0048] (2) homogeneous

[0049] After sterilization, use a high-pressure homogenizer for homogenization at a temperature of 72°C, a homogenization pressure of 14Mpa, and a time of 25 minutes;

[0050] (3) cooling

[0051] After homogenization, cool to 2°C with a plate exchanger;

[0052] (4) Aging

[0053] After cooling, enter the aging tank for aging, the temperature is 4°C, and the aging time is 3 hours;

[0054] (5) freezing ...

Embodiment 3

[0059] A method for preparing ice cream by using camel milk, which is composed of the following raw materials in weight ratio: 260 parts of camel milk, 150 parts of honey, 140 parts of unsalted butter, 50 parts of cream, 30 parts of eggs, 4 parts of stabilizer, and natural essence 2 servings.

[0060] The specific preparation method is:

[0061] (1) Mixing and sterilization

[0062] Mix the above raw materials into the mixing tank, the stirring speed of the mixing tank is 1500 rpm, filter after mixing, and sterilize at 80°C for 30 minutes;

[0063] (2) homogeneous

[0064] After sterilization, use a high-pressure homogenizer for homogenization at a temperature of 75°C, a homogenization pressure of 15Mpa, and a time of 30 minutes;

[0065] (3) cooling

[0066] After homogenization, cool to 4°C with a plate exchanger;

[0067] (4) Aging

[0068] After cooling, enter the aging tank for aging, the temperature is 6°C, and the aging time is 4 hours;

[0069] (5) freezing

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com