A magnetostrictive shrapnel-type microgripper driven by galfenol flakes

A technology of magnetostriction and shrapnel, which is applied in the field of micro-drives, can solve the problems of small deformation, incompatibility with semiconductor technology, and high driving voltage, and achieve the effects of high deformation accuracy, enhanced stiffness, and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

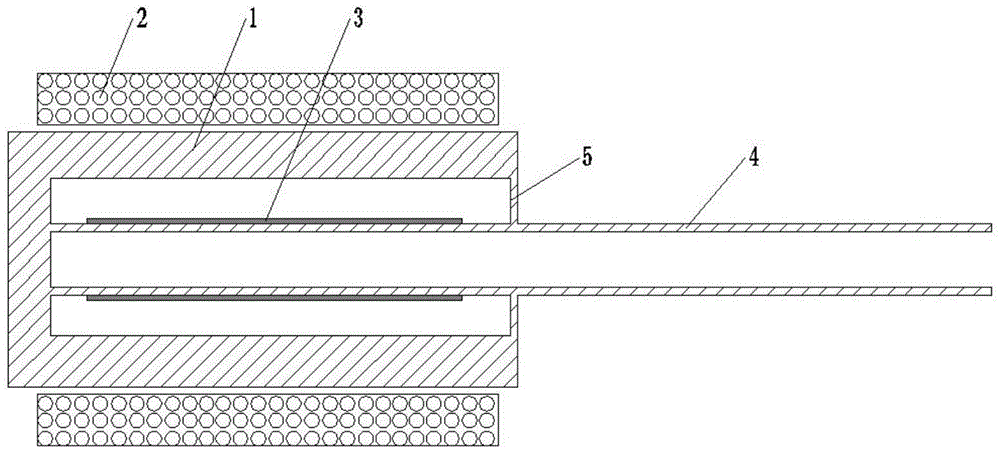

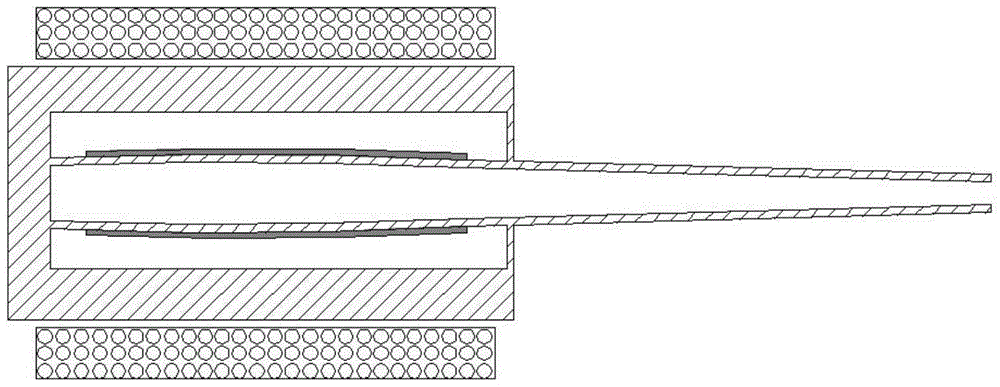

[0018] Such as figure 1 The magnetostrictive shrapnel type micro-clamp driven by a Galfenol sheet includes a clamp body 1, one end of the clamp body 1 is closed, the other end is open, and a coil 2 is wound outside the clamp body 1; The shrapnel 4, two shrapnels 4 are arranged oppositely, one end of the shrapnel 4 is connected with the closed end face of the pliers body 1, and the other end of the shrapnel 4 stretches out from the opening end of the pliers body 1; The shrapnel 4 is vertical to the supporting piece 5, one end of the supporting piece 5 is connected to the outer surface of the shrapnel 4, and the other end of the supporting piece 5 is connected to the inner wall of the pliers body 1; 3. The maximum magnetostriction direction of the Galfenol sheet 3 is consistent with the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com