An Uncertain Design Method for Heat Exchangers

A technology of uncertainty and design method, applied in the field of heat transfer, can solve the problems of inability to guarantee the design task of heat exchanger, increase of manufacturing and maintenance cost, large size and weight of heat exchanger, etc., to avoid substandard performance, reduce Weight gain, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

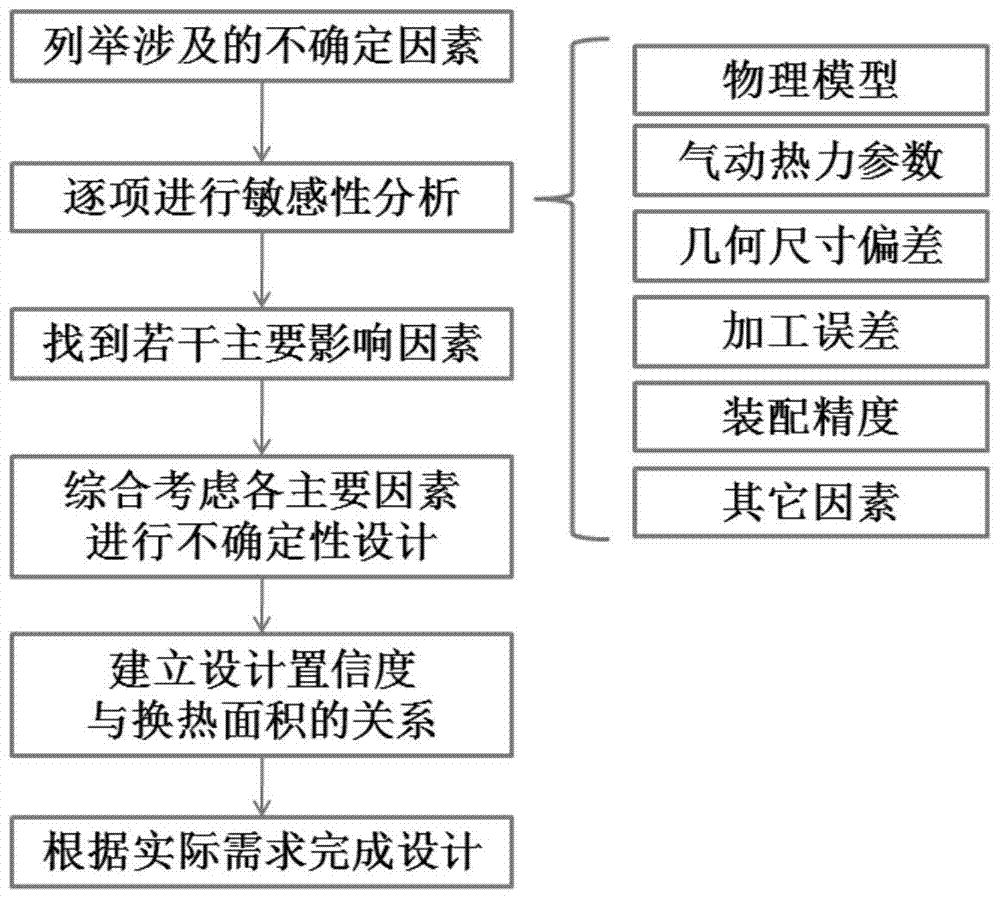

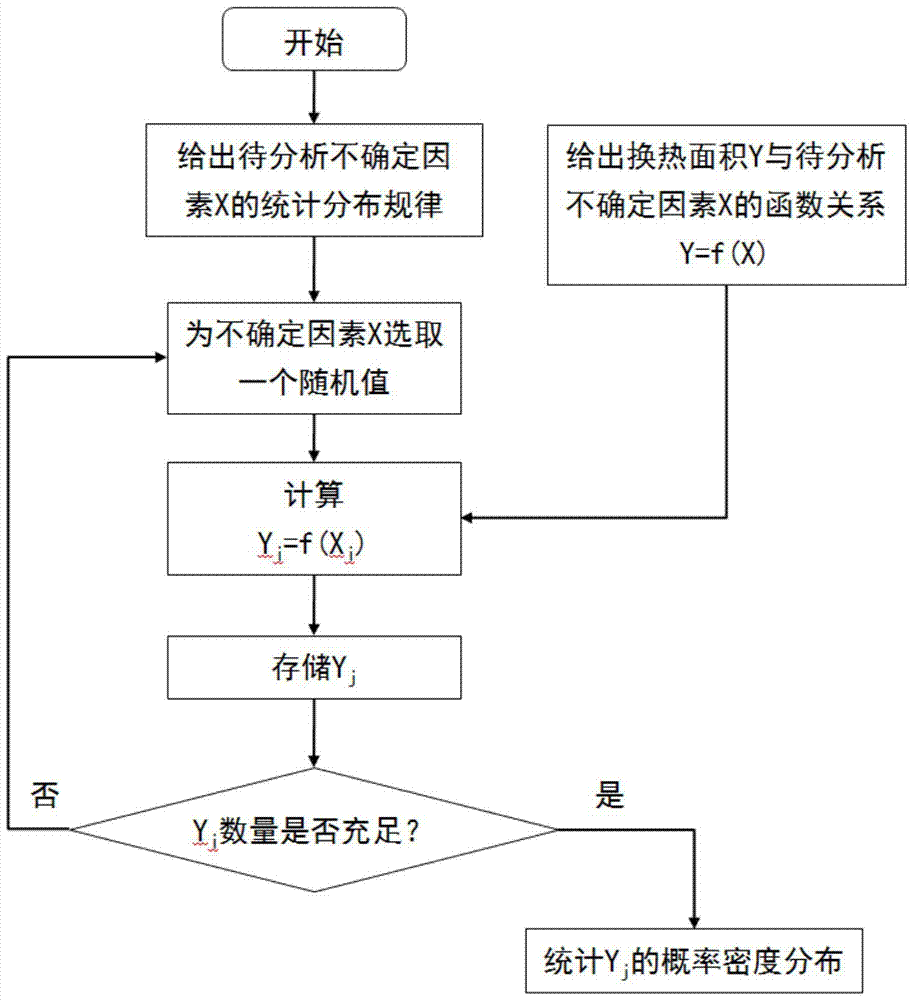

Method used

Image

Examples

Embodiment

[0024] It is used in the design of a certain type of precooler, in which the main flow is air and the cooling medium is helium. The design requires that one of the working fluids of the heat exchanger is air, the flow rate is 150kg / s, and the temperature drop of the air after passing through the heat exchanger is 250K. The air pressure is 0.5MPa, the inlet temperature is 750K; helium is used as the cooling medium, the pressure is 15MPa, and the temperature is 300K.

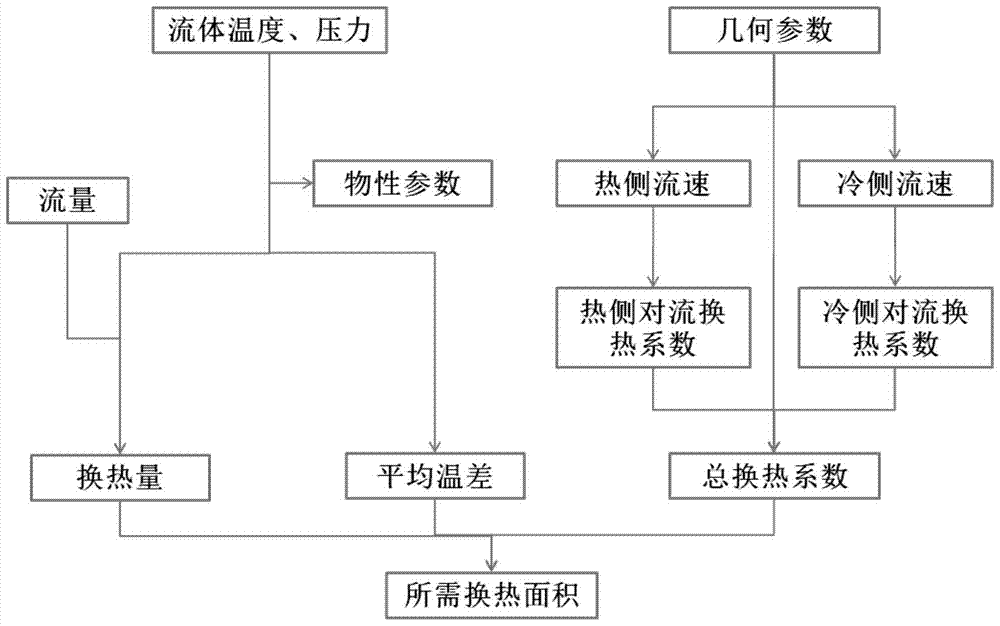

[0025] If according to the traditional design method, only the working state of the design point can be considered in the design, the process is as follows figure 1 shown. First obtain the physical parameters of the two working fluids at the design point, the air physical parameters are: density 2.39kg / m 3 , specific heat capacity 1082.6J / (kg*K), dynamic viscosity 3.5E-5, thermal conductivity 0.052. The physical parameters of helium are: density 18kg / m 3 , specific heat capacity 5181.8J / (kg*K), dynamic viscosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com