Liquid crystal photo-alignment control method

A control method and liquid crystal alignment layer technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of obvious chromatic aberration operation and complexity in the left and right parts of the panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

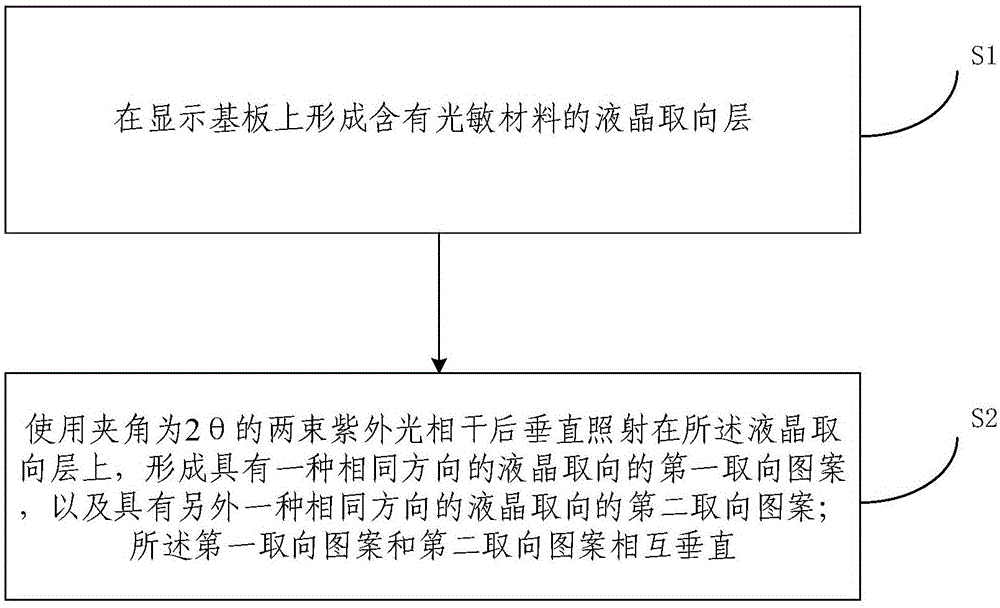

[0036] Such as figure 1 As shown, the embodiment of the present invention provides a method for controlling the optical alignment of liquid crystals, including:

[0037] Step S1, forming a liquid crystal alignment layer containing a photosensitive material on the display substrate;

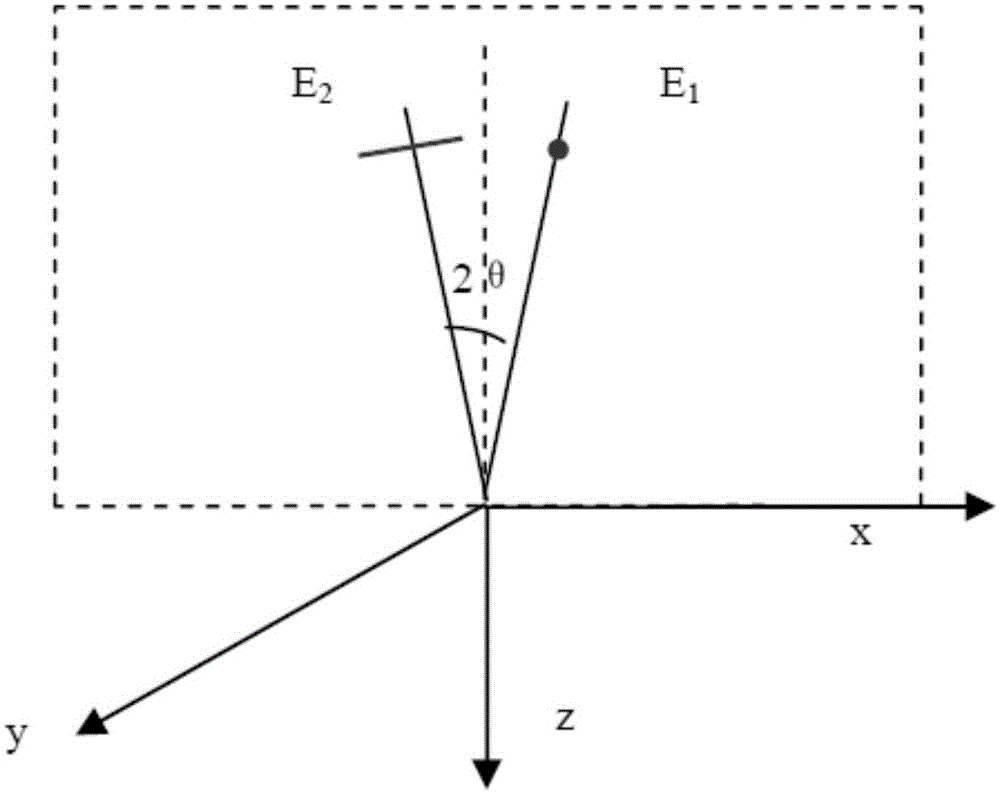

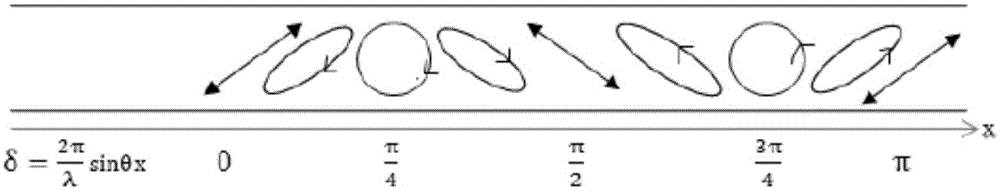

[0038] Step S2, using two beams of ultraviolet light with an included angle of 2θ to coherently irradiate the liquid crystal alignment layer vertically to form a first alignment pattern with one liquid crystal alignment in the same direction, and another liquid crystal alignment with the same direction The second alignment pattern; the first alignment pattern and the second alignment pattern are perpendicular to each other;

[0039] Wherein, the plane where the two beams of ultraviolet light are located is perpendicular to the plane where the liquid crystal alignment la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com