Downhole power cable insulation monitoring device

A cable insulation and monitoring device technology, applied in directions such as fault locations, can solve problems such as difficult implementation, low sensitivity, and low sensitivity, and achieve the effects of avoiding economic losses, ensuring operational safety, and improving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

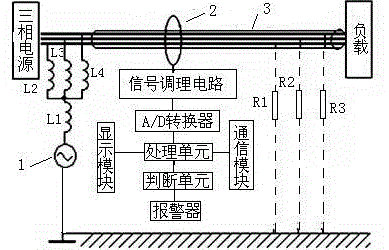

[0023] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

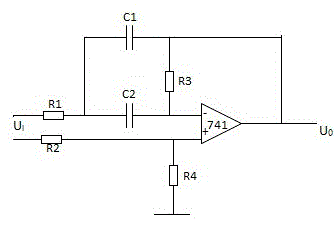

[0024] Such as figure 1 As shown, a downhole power cable insulation monitoring device includes a low-frequency voltage source 1, first to fourth inductors, a Hall current sensor 2, a signal conditioning circuit, an A / D converter, a processing module, a display module, an alarm and The communication module, the processing module includes a processing unit and a judgment unit; the signal conditioning circuit includes a trap circuit, a filter circuit, an amplification circuit and a rectification circuit connected in sequence; wherein,

[0025] The low-frequency voltage source is connected to one end of the first inductance, the other end of the first inductance is respectively connected to one end of the second to fourth inductances, and the other ends of the second to fourth inductances are respectively connected to the three-phase wires in the cable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com