Electric motorcycle inner rotor motor double cone friction transmission self-adaptive variable speed assembly

An inner rotor motor, electric motorcycle technology, applied in transmission parts, transmission control, mechanical equipment, etc., can solve the problems of small torque-rotation speed changes that cannot meet road use, tolerances, etc. Wear resistance, the effect of increasing the friction surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

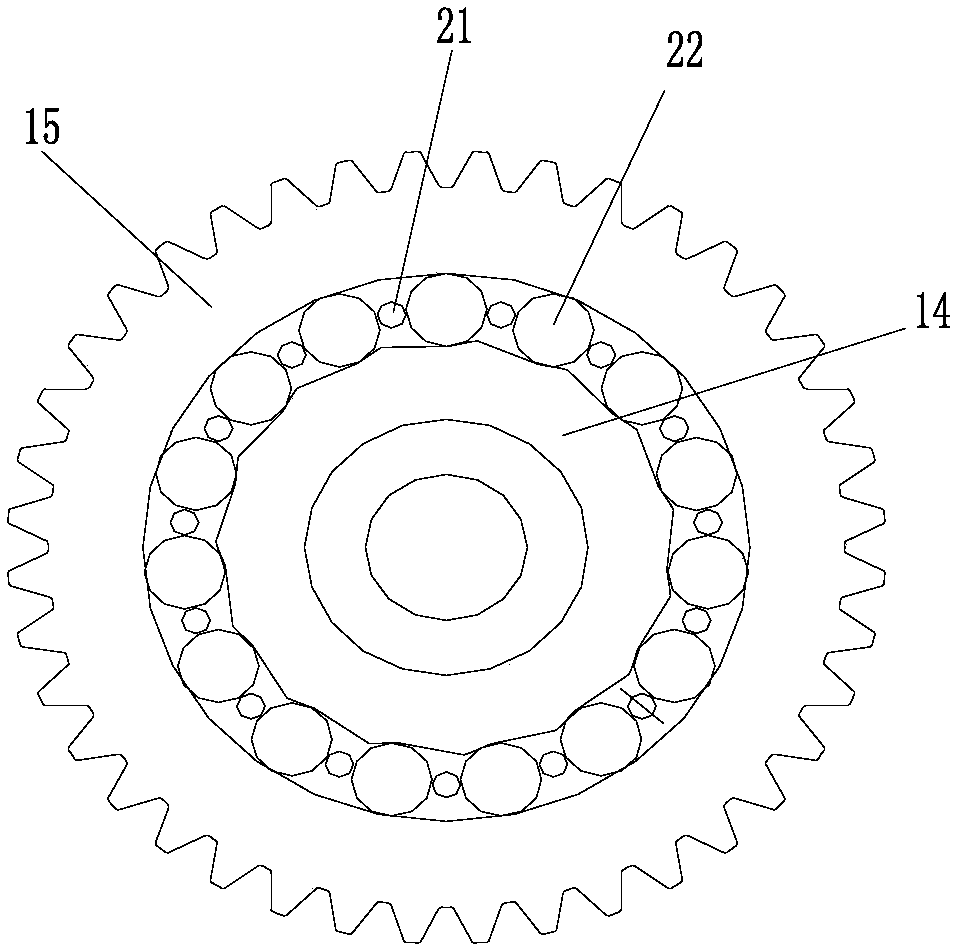

[0024] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 Schematic diagram of the structure of the overrunning clutch, image 3 It is a circumferential cross-sectional view of an overrunning clutch, as shown in the figure: the double-cone friction transmission self-adaptive automatic variable speed drive assembly of the electric motorcycle inner rotor motor of the present invention includes a drive motor, a casing 3, and a casing 3 that rotates and cooperates with the casing 3. Power output transmission shaft 1, the box body 3 has a mounting part for side hanging on the hub side, or is used to form the hub; when in use, the motor is fixedly connected to the box body 3, and the box body 3 is fixedly connected to the wheel hub side on the frame of the vehicle to form a side hanging structure;

[0025] It also includes a slow gear transmission mechanism and a mechanical intelligent adaptive transmission assembly arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com