Air filter for efficient engine

An air filter and engine technology, which is applied to fuel air filters, engine components, machines/engines, etc., can solve the problems of difficult cleaning of filter elements, inability to completely filter particulate matter, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

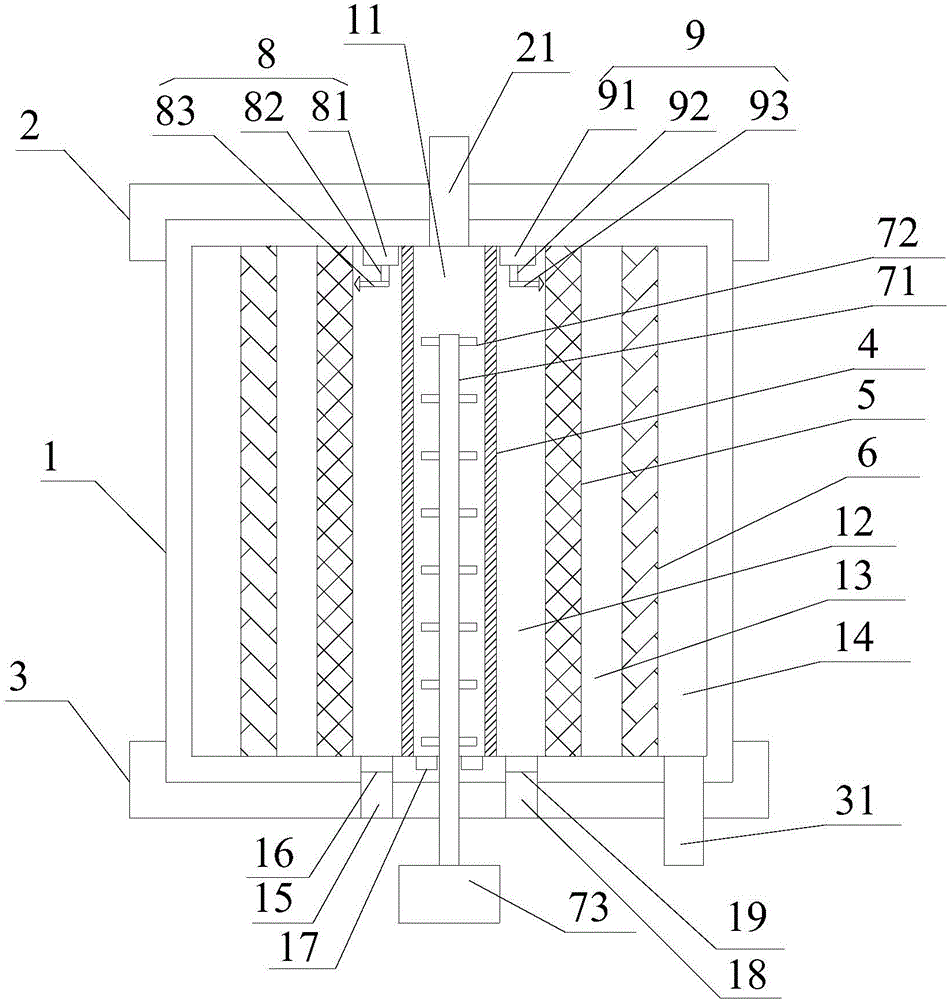

[0016] refer to figure 1 , the present invention proposes an air filter for a high-efficiency engine, including a filter cartridge 1, a first end cover 2, a second end cover 3, and a controller. The first end cover 2 and the second end cover 3 are arranged on the filter cartridge 1 The first end cover 2 is provided with an air inlet 21 , and the second end cover 3 is provided with an air outlet 31 .

[0017] The first cavity is provided with an inner filter cartridge 4, a first filter element 5 and a second filter element 6, the inner filter cartridge 4 is arranged inside the first filter element 5, the first filter element 5 is arranged inside the second filter element 6, and the inner filter cartridge 4, The first filter element 5 and the second filter element 6 divide the interior of the filter cartridge into a first filter cavity 11, a second filter cavity 12, a third filter cavity 13 and a fourth filter cavity 14, and the air inlet 21 communicates with the first filter ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com