A system and method for improving coalbed methane extraction volume in surface drilling and extraction of old gobs

A surface drilling and coalbed methane technology, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of high accident rate, difficult construction, low porosity rate, etc., so as to save economic cost, Improve rock breaking efficiency and fast crushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

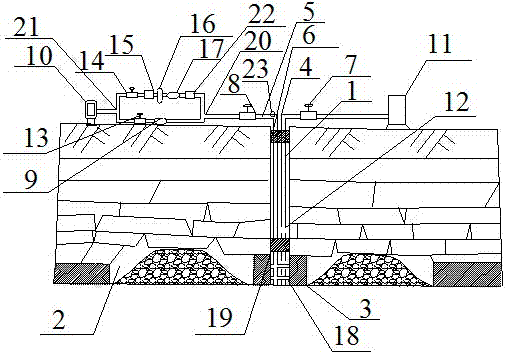

[0029] Such as figure 1 As shown, the present invention provides a system for improving the extraction volume of coalbed methane in the old goaf area of ground drilling, including extraction drilling 1, surface extraction station 11, valve II 7, extraction pipe 4, injection pipe 5, pressure Table 23, valve Ⅰ 8, tee pipe Ⅰ 20, heating device 22, liquid booster pump 17, liquid CO 2 Storage tank 16, refrigeration device 15, valve III 14, gas booster pump 9, valve IV 13, tee pipe II 21, CO 2 The gas storage tank 10, the extraction well 1 leads to the bottom of the coal pillar 3, the extraction pipe 4 and the injection pipe 5 are sent to the bottom of the coal pillar 3 through the extraction well 1; the sealing section I (6) is flush with the ground, The sealing section II (19) is located 0.5~2m above the coal pillar; the injection pipe 5 above the ground is connected to the pressure gauge 23, the valve I8, and the tee pipe I20, and the other end of the tee pipe I20 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com