Double-sided adhesive tape attaching device and method

A double-sided adhesive and sticking technology, which is applied in lamination devices, mounting board safety devices, chemical instruments and methods, etc., can solve the problems of low sticking accuracy and sticking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

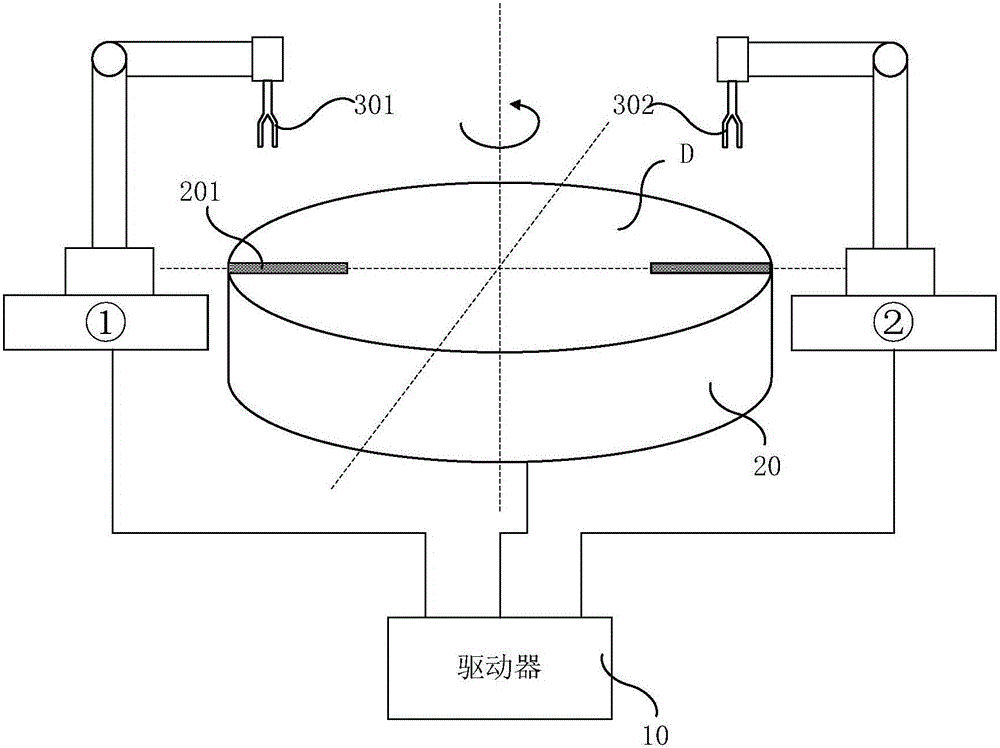

[0051] In this embodiment, the manipulator is as figure 1 As shown, it includes a double-sided tape manipulator 301 and a circuit board manipulator 302, and the preset stations include the first station ① and the second station ②.

[0052] In this case, the worktable 20 is connected with the driver 10 for rotating under the driving of the driver 10 . Wherein, it can be rotated clockwise or counterclockwise, which is not limited in the present invention.

[0053] Based on this, the double-sided tape manipulator 301 is located at the first station ①, and is used to place a double-sided tape 40 on the positioning mechanism 201 when the workbench 20 rotates a positioning mechanism 201 to the first station ①, and The first protective film 401 of the double-sided adhesive is torn off, exposing the first adhesive surface A.

[0054] The circuit board manipulator 302 is located at the second station ②, and is used to press the double-sided adhesive tape 40 located at the first stati...

Embodiment 2

[0058] In this embodiment, the above-mentioned manipulator is as Figure 3a As shown, it may include a first double-sided tape manipulator 303 , a second double-sided tape manipulator 304 , a first circuit board manipulator 305 , and a second circuit board manipulator 306 . The preset stations include a first station ①, a second station ②, a third station ③ and a fourth station ④.

[0059] In this case, the worktable 20 is connected with the driver 10 for rotating under the driving of the driver 10 .

[0060] Based on this, the first double-sided tape manipulator 303 is located at the first station ①, and is used to place a double-sided tape 40 on the positioning mechanism 201 when the workbench 20 rotates a positioning mechanism 201 to the first station ①.

[0061] The second double-sided adhesive manipulator 304 is located at the second station ②, and is used to turn the double-sided adhesive located at the second station ② when the workbench 20 rotates the double-sided adh...

Embodiment 3

[0093] In this embodiment, the manipulator is as figure 1 As shown, it includes a double-sided tape manipulator 301 and a circuit board manipulator 302, and the preset stations include the first station ① and the second station ②.

[0094] In this case, the method, such as Figure 6 shown, including:

[0095]S201, the workbench 20 is rotated, and a positioning mechanism 201 is rotated to the first station ①.

[0096] S202 , the double-sided tape manipulator 301 located at the first station ① places a double-sided tape 40 on the positioning mechanism 201 .

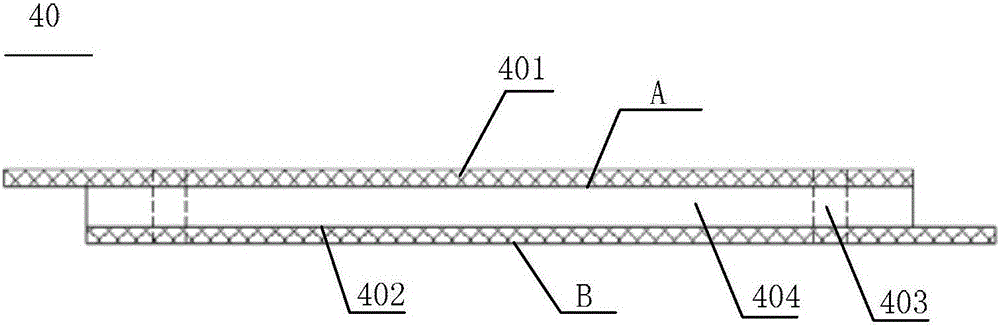

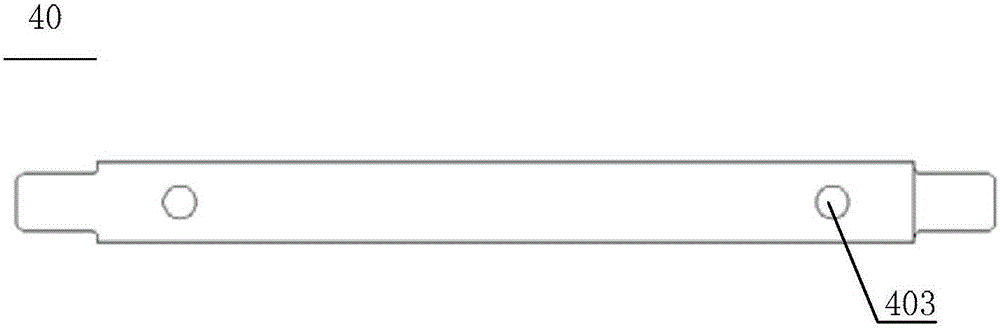

[0097] S203 , the positioning mechanism 201 fixes the adhesive layer 404 of the double-sided adhesive tape 40 and the second protective film 402 .

[0098] S204. The double-sided tape manipulator 301 located at the first station ① tears off the first protective film 401 of the double-sided tape 40, exposing the first adhesive surface A.

[0099] S205, the workbench 20 is rotated, and the double-sided adhesive tape 40 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com