Ventilating bacteria culture-saccharification and fermentation integrated preparation process for rice-flavor baijiu and special bioreactor

A bioreactor, bacteria-cultivation and saccharification technology, which is applied in the field of liquor brewing, can solve the problems of unsatisfactory saccharification effect, influence of wine yield and flavor, poor bacteria-cultivation and saccharification effect, etc. Conducive to the effect of ventilation to cultivate Rhizopus and to promote rapid reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An integrated production process of rice-flavored liquor through ventilated culture, saccharification and fermentation, comprising the following steps:

[0037] (1) Add koji to steamed rice: Cook the soaked indica rice by steam cooking or stewing with water to control the fullness of the rice grains, and the water content of the rice is about 60%; after the rice is cooled to 37°C, mix it with The medicinal Xiaoqu of Chinese herbal medicine, the dosage of medicinal Xiaoqu is 1.5% of the amount of rice;

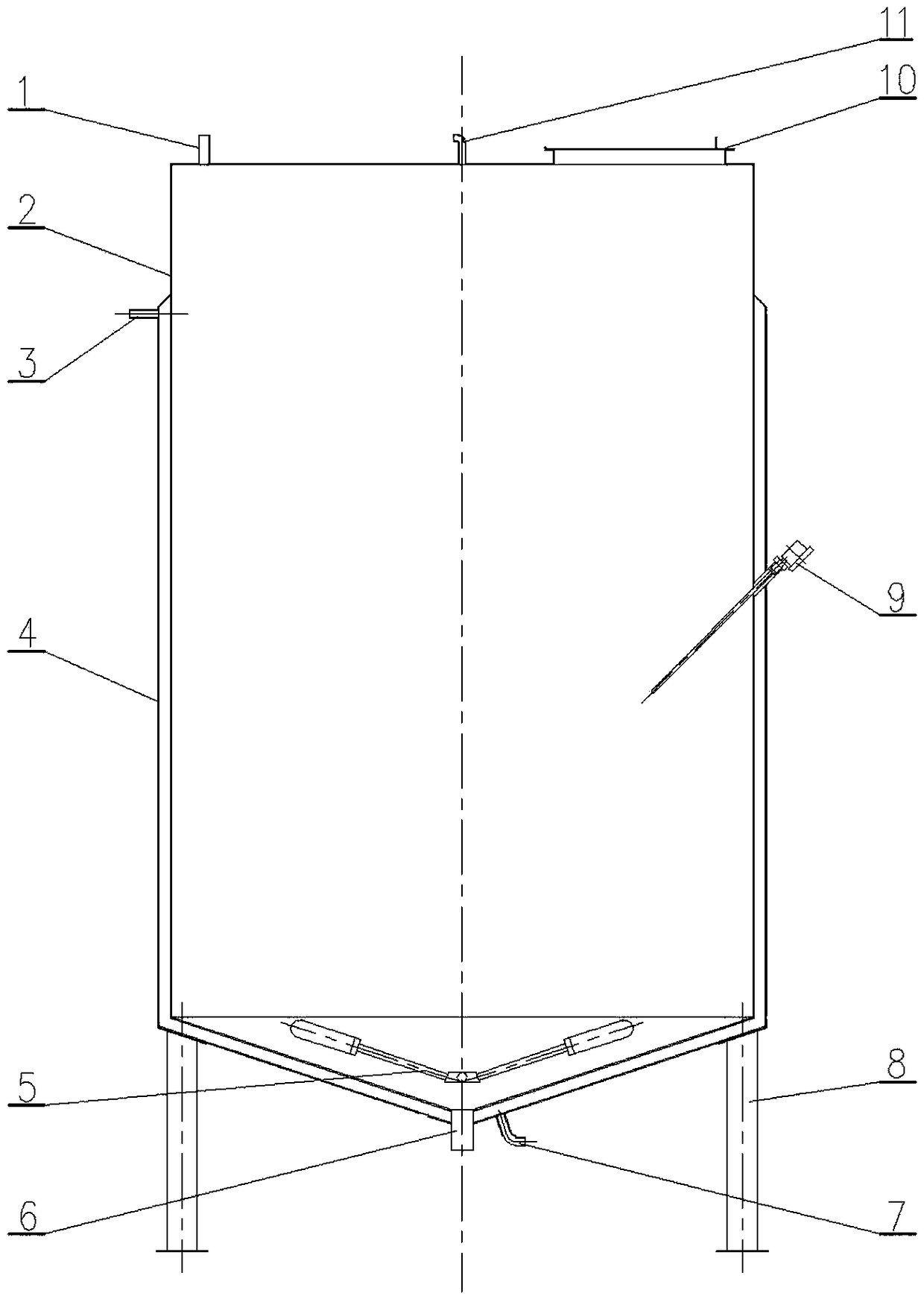

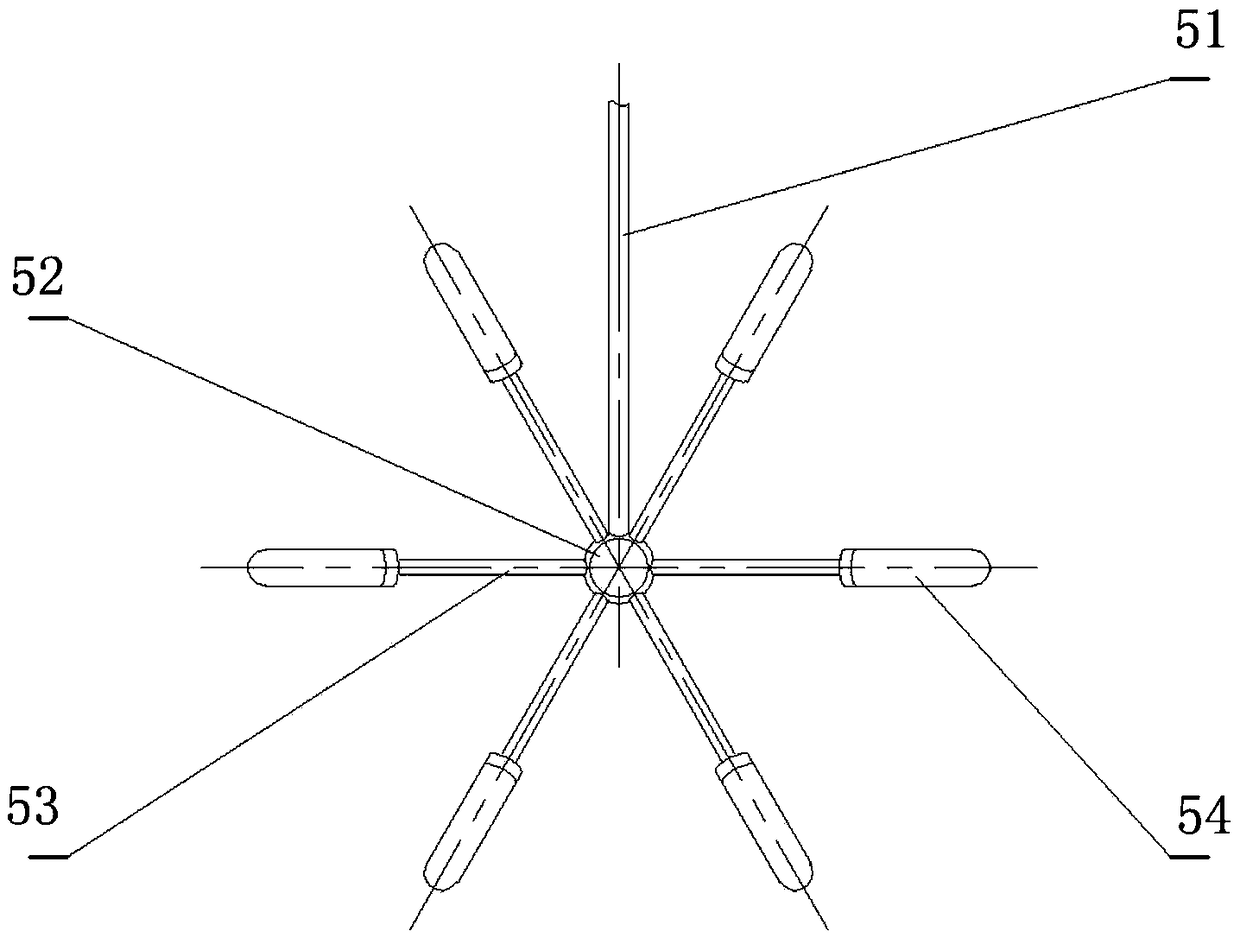

[0038] (2) Spreading material: put 20 tons of rice mixed with koji powder into a volume of 60m 3 In the dedicated bioreactor, pave and control the feeding temperature to 35°C;

[0039] (3) Bacteria cultivation and saccharification with ventilation: open the air supply valve, manually introduce clean air, and carry out ventilation cultivation and saccharification. During the cultivation and saccharification process, the ventilation rate is adjusted to 0.5 cubic meters per ...

Embodiment 2

[0047] An integrated production process of rice-flavored liquor through ventilated culture, saccharification and fermentation, comprising the following steps:

[0048] (1) Steamed rice with koji: Cook the soaked indica rice by steaming or adding water to stew, so that the rice grains are full and the water content of the rice is about 65%; after the rice is cooled to 40°C, mix it with Rice bran cake-shaped koji, the dosage is 2.5% of the amount of rice;

[0049] (2) Spreading material: put 15 tons of rice mixed with koji powder into a volume of 60m 3 In the dedicated bioreactor, pave and control the feeding temperature to 40°C;

[0050] (3) Bacteria cultivation and saccharification with ventilation: open the air supply valve, manually introduce clean air, and carry out ventilation cultivation and saccharification. During the cultivation and saccharification process, the ventilation rate is adjusted to 0.8 cubic meters per ton of rice min, and the temperature is controlled at ...

Embodiment 3

[0058] An integrated production process of rice-flavored liquor through ventilated culture, saccharification and fermentation, comprising the following steps:

[0059] (1) Steamed rice with koji: Cook the soaked indica rice by steam cooking or stewing with water to control the fullness of the rice grains, and the water content of the rice is about 55%; after the rice is cooled to 32°C, mix it with Drug-free Xiaoqu, the dosage is 0.05% of the amount of rice;

[0060] (2) Spreading material: put 10 tons of rice mixed with koji powder into a 60m3 3 In the dedicated bioreactor, pave and control the feeding temperature to 30°C;

[0061] (3) Bacteria cultivation and saccharification with ventilation: open the air supply valve, manually introduce clean air, and carry out ventilation cultivation and saccharification. During the cultivation and saccharification process, the ventilation rate is adjusted to 0.1 cubic meters per ton of rice min, and the temperature is controlled at 40 ℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com