Protective film with rainbow ring resistance and preparation method thereof

A manufacturing method and an environmentally friendly technology, applied in chemical instruments and methods, household appliances, other household appliances, etc., can solve problems such as affecting people's visual effects, achieve good anti-rainbow effect, good application prospects, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

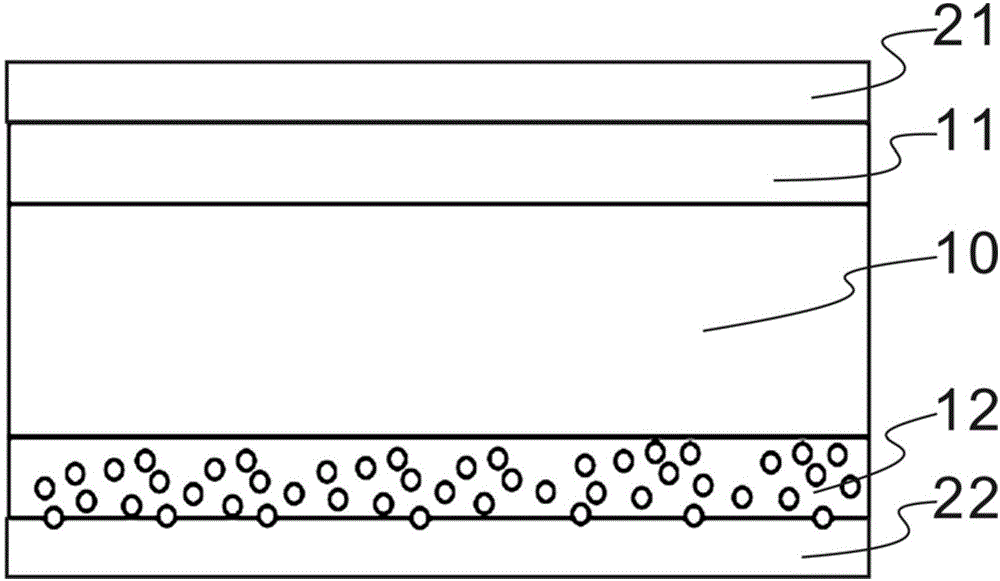

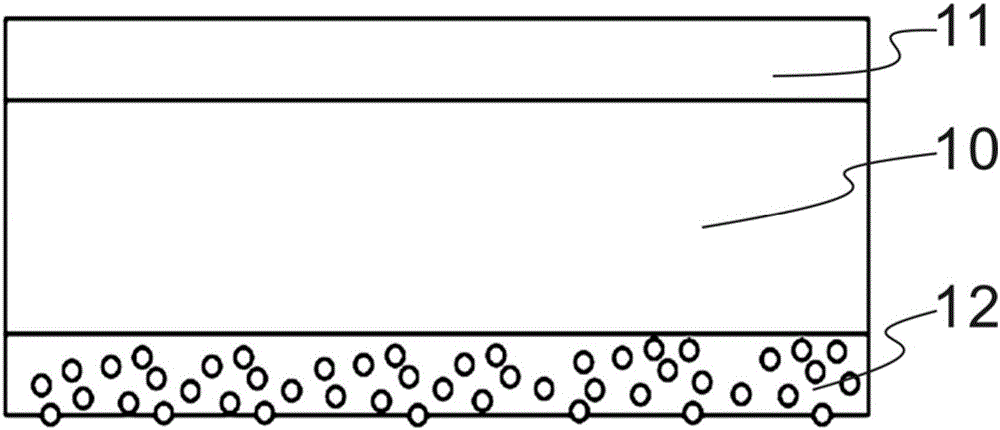

[0036] The main layer of the product designed by the present invention is divided into three layers in total, and the main layer (use layer) includes: a hardened coating 11 , a base material 10 , and a rough coating 12 .

[0037] Firstly, a layer of transparent hardened coating 11 is coated on the upper surface of the substrate 10 . The surface hardness of the product treated by the hard coating 11 can reach more than 2H, up to 6H.

[0038] The hardness test is to use a pencil tester to test the surface hardness with a force of 500g. At the same time, the product has a certain anti-friction effect, and the surface of 0000# steel wool has been tested for more than 20 times without obvious scratches.

[0039] Then the lower surface of the substrate 10 is coated with a rough coating 12 with a certain surface roughness, and the rough coating 12 is coated on the lower surface of the substrate 10, so that the lower surface of the substrate 10 has a certain concave-convex effect , ...

Embodiment 2

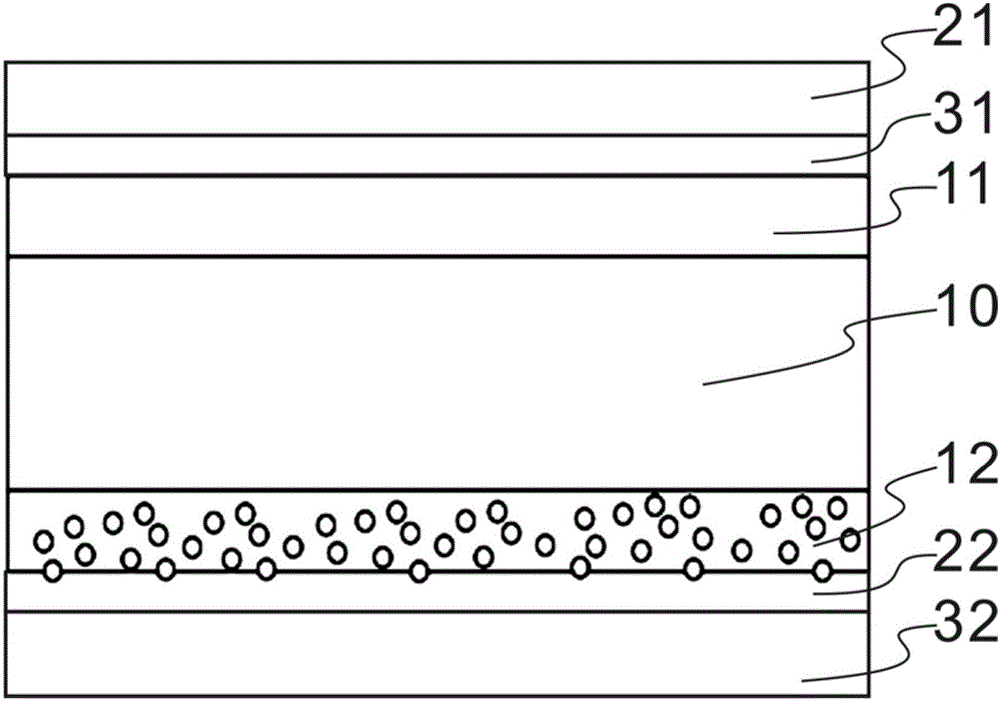

[0042] In the present invention, different coating treatments are applied on the front and back sides of the base material 10 to achieve a protective film for resisting rainbow rings with a certain anti-scratch performance.

[0043] The inner surface of the transparent film (upper release film 21, lower release film 22) can be selectively coated with an adhesive layer (upper adhesive layer 31, lower adhesive layer 32), or not coated with an adhesive layer. Depends on the product demand. When the adhesive layer (the upper adhesive layer 31 and the lower adhesive layer 32) needs to be coated, silica gel, acrylic glue, pressure-sensitive adhesive, or OCA glue can be used.

[0044] The upper and lower two layers of peeling film (upper peeling film 21, lower peeling film 22) are respectively compounded on the upper and lower sides of the main layer (use layer) by coating the adhesive layer (upper adhesive layer 31, lower adhesive layer 32) Both sides, forming a protective effect. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com