Repairing and strengthening method for tool of high-temperature in-service shearing equipment

A high-temperature service and cutting tool technology, which is applied in the fields of machinery manufacturing and material processing, can solve the problems of not being able to improve the high-temperature and wear-resistant performance of cutting tools, the alloy layer is easy to fall off, and low efficiency, so as to overcome the lack of repair and strengthening and improve high-temperature resistance Wear-resistant performance, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

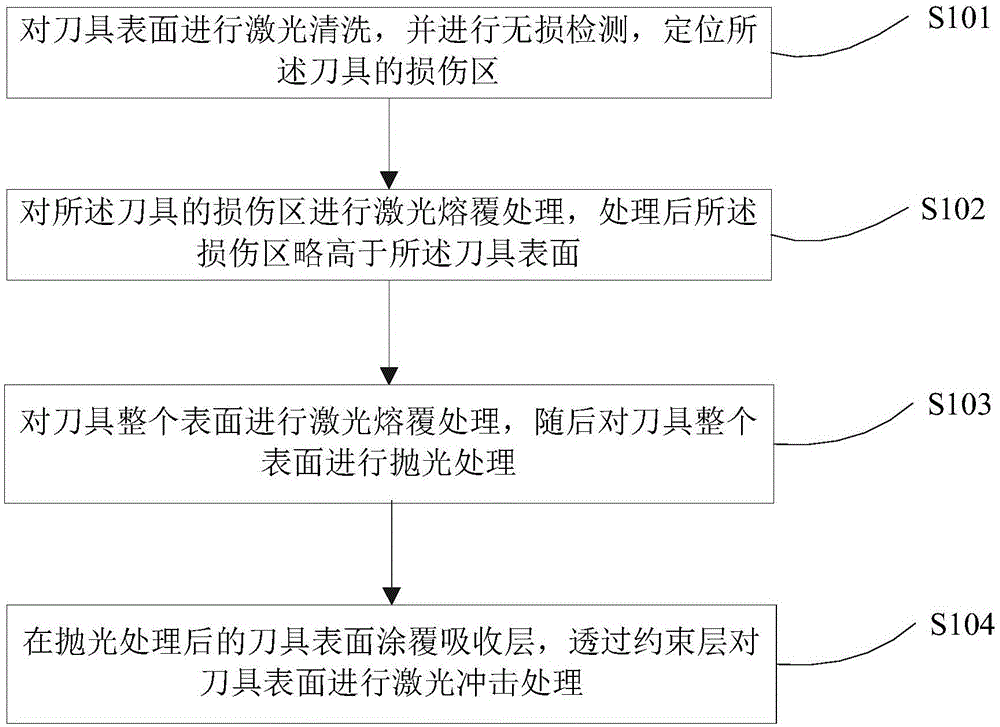

Method used

Image

Examples

Embodiment 2

[0035] This embodiment provides a process of repairing and strengthening the shear equipment cutter of T12A tool steel. Among them, the chemical composition of the T12A shear equipment tool is: C1.15-1.24; Si≦0.35; Mn≦0.4; S≦0.032; P≦0.035, and the hardness is 217HB.

[0036] Laser cleaning is performed on the disassembled T12A shearing equipment tool while blowing nitrogen. The power of the YAG laser for laser cleaning is 30W and the frequency is 10Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com