Method for casting end cap of transmission end of traction motor on subway locomotive

A technology for traction motors and locomotives, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve the problems of large amount of self-setting resin, slow cooling speed of castings, and large machining allowance of castings, and achieves less resin sand. , stable production process and reduced machining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

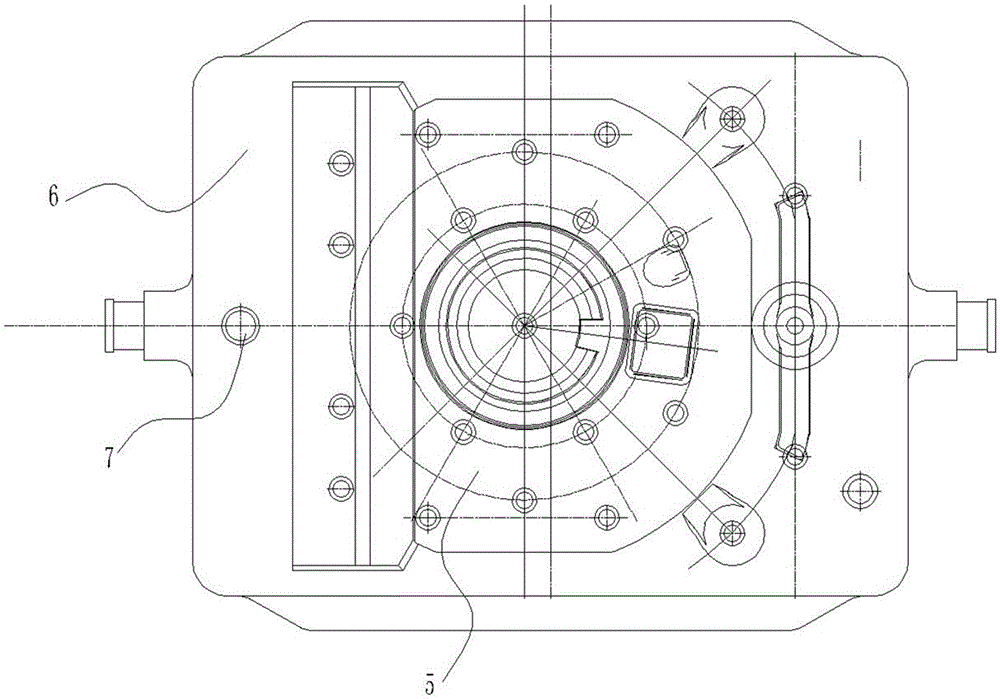

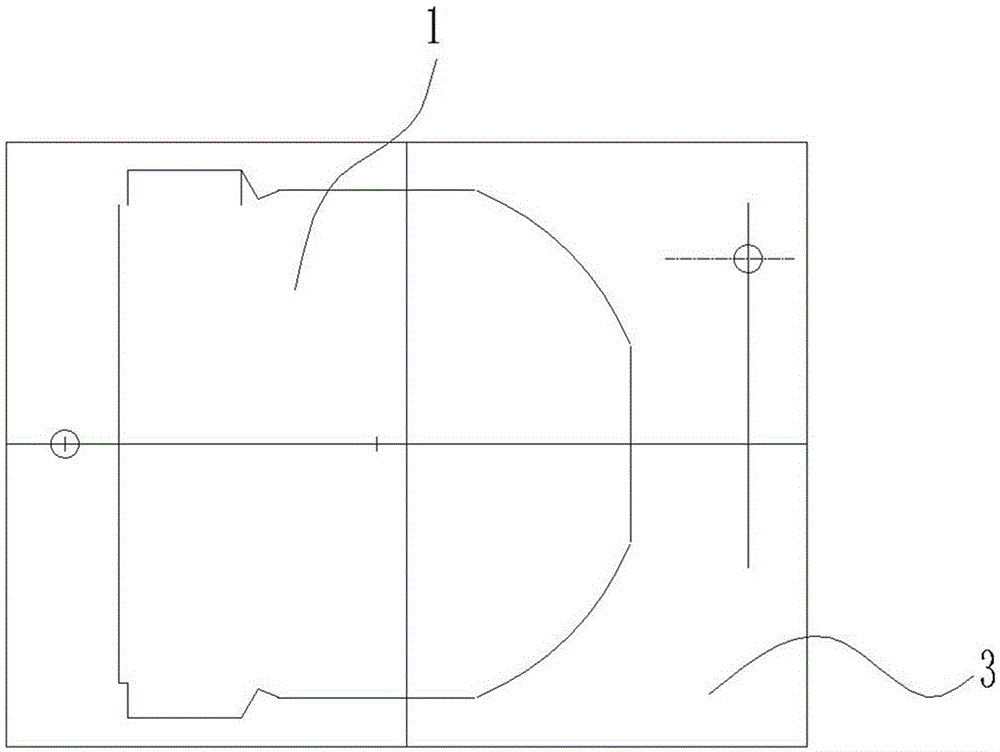

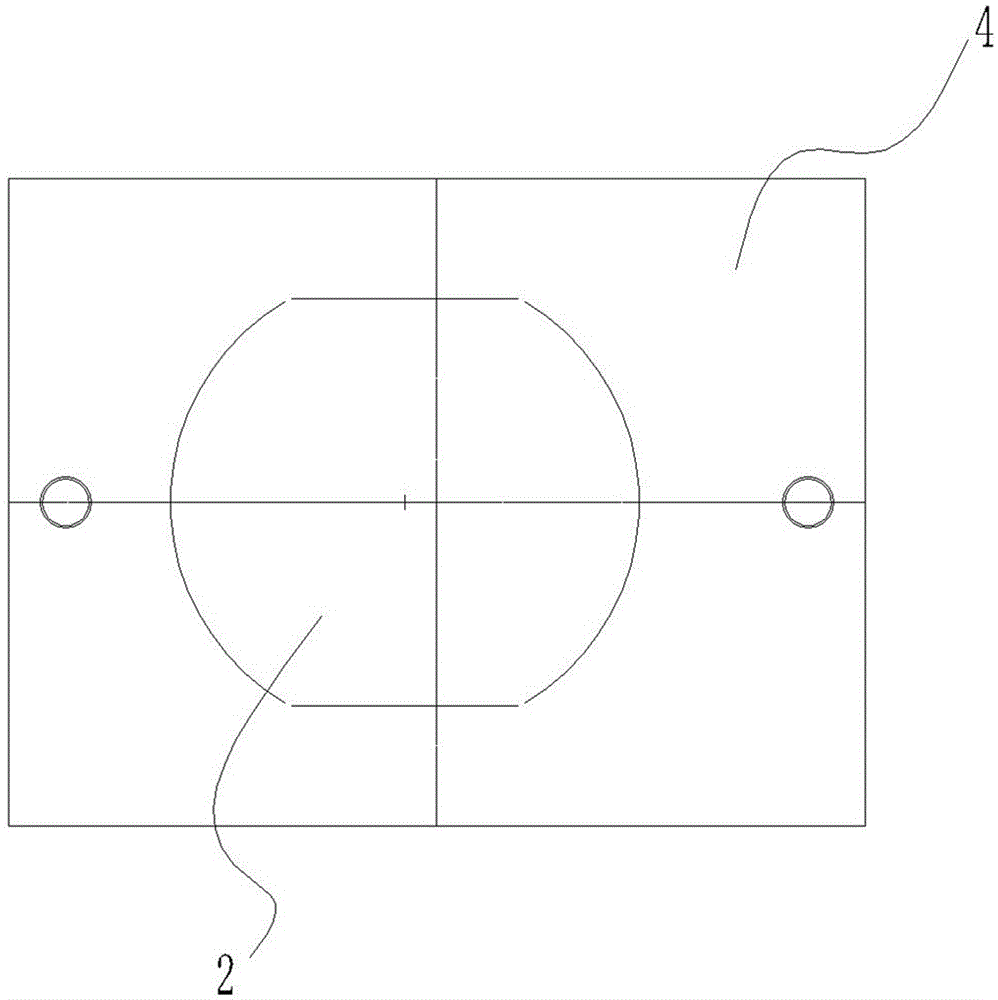

[0037] A casting method for the transmission end cover of the traction motor on a subway locomotive. The casting method adopts an iron mold sand-covering process for casting. The specific steps are as follows: (1) Design a set that is completely consistent with the shape of the transmission end cover of the traction motor on a subway locomotive. The model is used as a master mold, and the master mold includes a tooling mold for designing and manufacturing the transmission end cover of the traction motor on the subway locomotive, a pouring system, a heating plate and a base. Such as figure 2 , Figure 6 , Figure 7 As shown, the upper mold plate 3 is provided with a transmission end cover upper mold 1, and the transmission end cover upper mold 1 is provided with a cavity for the external structure of the transmission end cover. Such as image 3 , Figure 8 , Figure 9 As shown, the lower mold plate 4 is provided with a transmission end cover lower mold 2, and the transmis...

Embodiment 2

[0040] A casting method for the transmission end cover of the traction motor on a subway locomotive. The casting method adopts an iron mold sand-covering process for casting. The specific steps are as follows: (1) Design a set that is completely consistent with the shape of the transmission end cover of the traction motor on a subway locomotive. The model is used as a master mold, and the master mold includes a tooling mold for designing and manufacturing the transmission end cover of the traction motor on the subway locomotive, a pouring system, a heating plate and a base. Such as figure 2 , Figure 6 , Figure 7 As shown, the upper mold plate 3 is provided with a transmission end cover upper mold 1, and the transmission end cover upper mold 1 is provided with a cavity for the external structure of the transmission end cover. Such as image 3 , Figure 8 , Figure 9 As shown, the lower mold plate 4 is provided with a transmission end cover lower mold 2, and the transmis...

Embodiment 3

[0043] A casting method for the transmission end cover of the traction motor on a subway locomotive. The casting method adopts an iron mold sand-covering process for casting. The specific steps are as follows: (1) Design a set that is completely consistent with the shape of the transmission end cover of the traction motor on a subway locomotive. The model is used as a master mold, and the master mold includes a tooling mold for designing and manufacturing the transmission end cover of the traction motor on the subway locomotive, a pouring system, a heating plate and a base. Such as figure 2 , Figure 6 , Figure 7 As shown, the upper mold plate 3 is provided with a transmission end cover upper mold 1, and the transmission end cover upper mold 1 is provided with a cavity for the external structure of the transmission end cover. Such as image 3 , Figure 8 , Figure 9 As shown, the lower mold plate 4 is provided with a transmission end cover lower mold 2, and the transmis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com