High-speed mixing device used for producing fertilizers

A high-speed mixing and fertilizer technology, applied in the direction of mixers, mixers with rotating stirring devices, dissolution, etc., can solve the problems of poor uniformity of trace elements and difficult trace elements mixed into fertilizers, and achieve the effect of avoiding pollution from steam discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

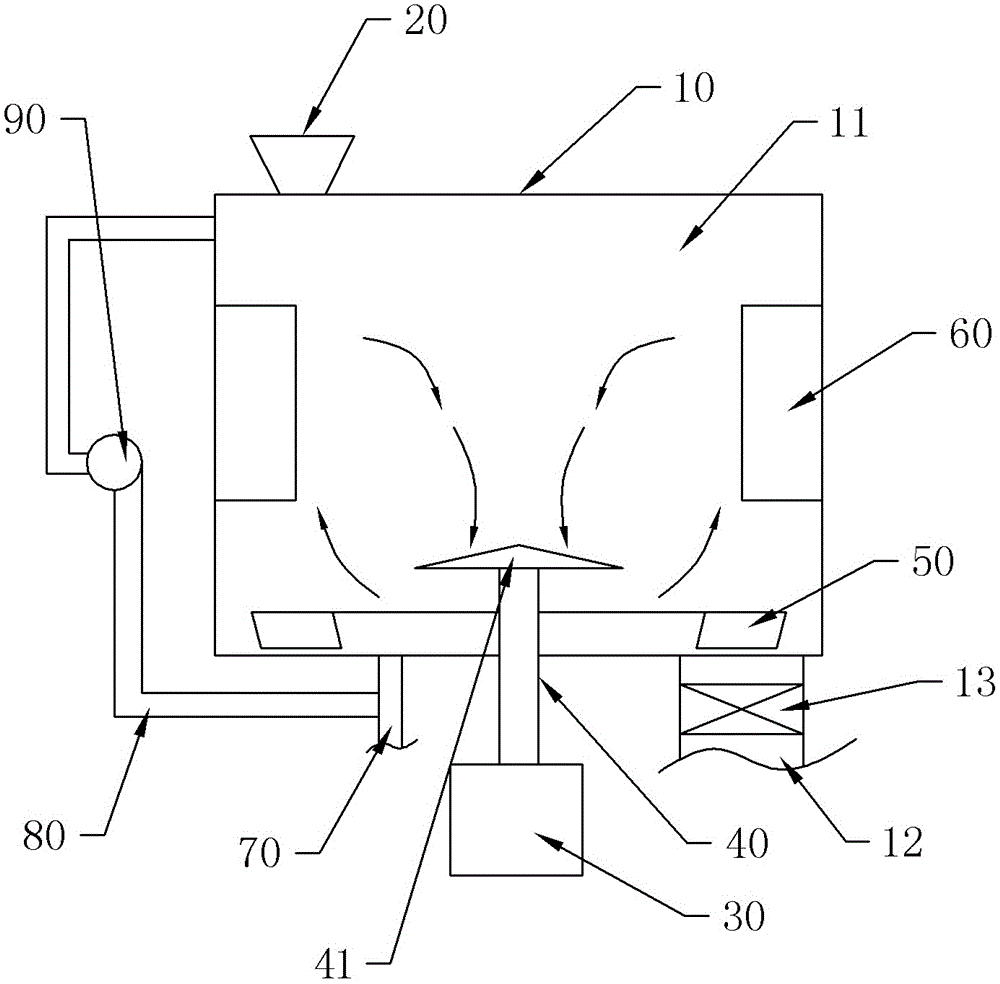

[0015] The reference numerals in the accompanying drawings include: mixing tank 10, mixing chamber 11, hopper 20, motor 30, drive shaft 40, sliding plate 41, impeller 50, baffle plate 60, steam pipe 70, circulation pipe 80, circulating pump 90, discharge port 12, valve 13.

[0016] The embodiment is basically as attached figure 1 Shown: a high-speed mixing device for producing fertilizers, including a mixing tank 10 with a mixing chamber 11, a motor 30, an impeller 50, a drive shaft 40 and a motor 30, the mixing tank 10 is cylindrical, and the mixing The upper part of the barrel 10 is provided with a hopper 20, the lower part of the mixing barrel 10 is provided with a discharge port 12, the discharge port 12 is provided with a valve 13, the output end of the motor 30 is connected with the drive shaft 40, and the rotating speed of the motor 30 is 900r / min. The motor 30 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com