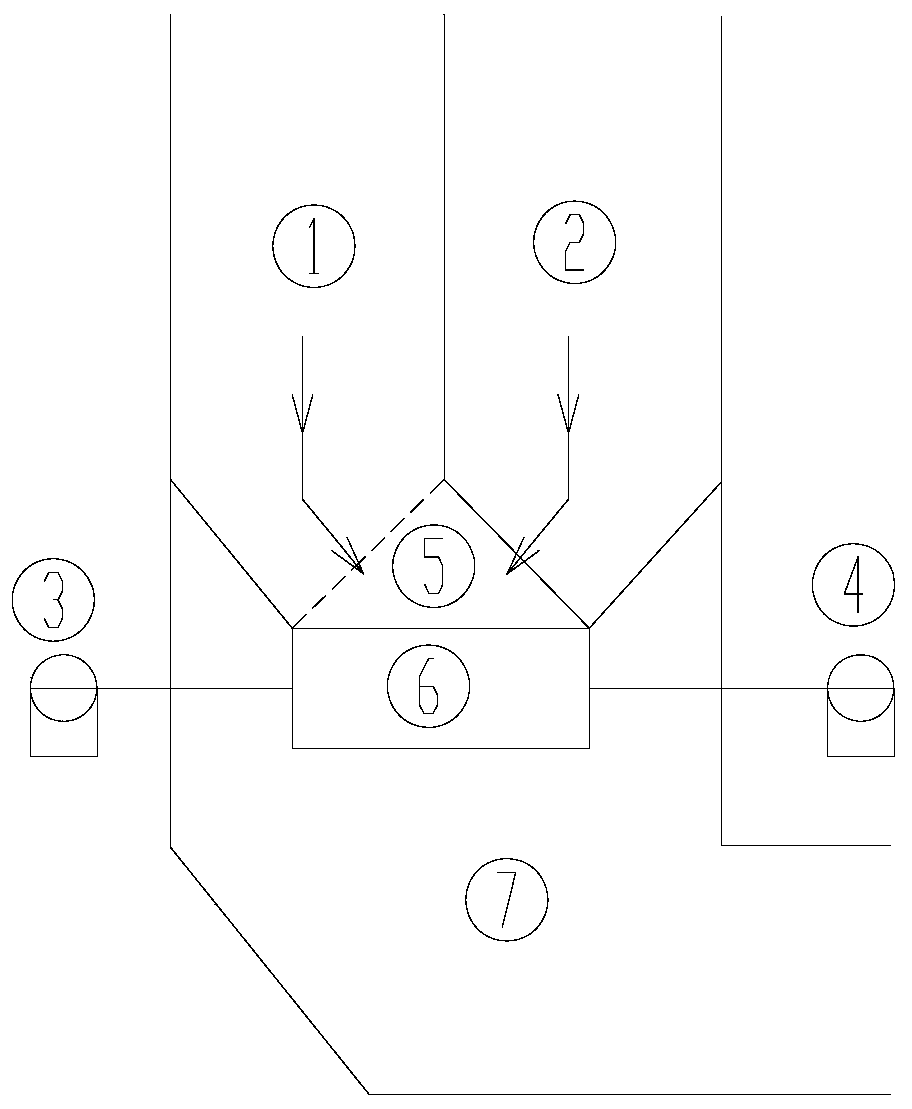

Merged flue adjusting baffle cross arrangement structure and method

A technology of adjusting baffles and cross arrangement, which is applied in the direction of combustion method, exhaust gas device, combustion product treatment, etc., can solve the problem of uneven temperature field of flue gas, and achieve the effect of uniform temperature field and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

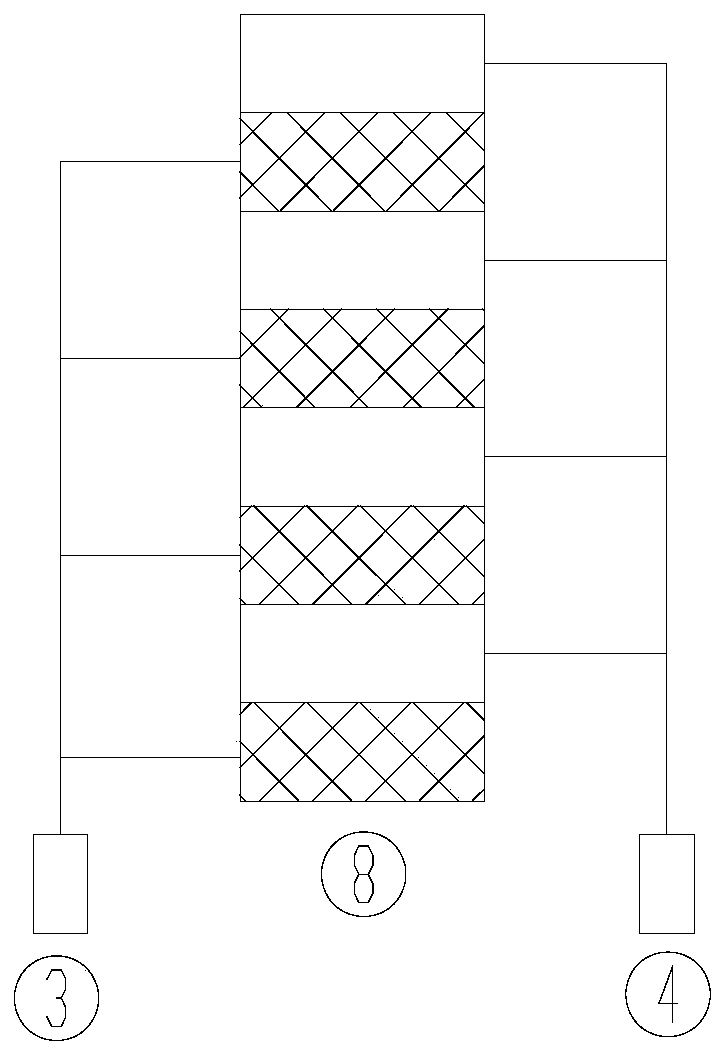

[0040]In a power plant, a boiler with double flue baffles at the rear is used for temperature regulation. In actual operation, when the load is 40% to 60%, the flue gas temperature at the outlet of the front partition flue is 340°C, and the flue temperature at the outlet of the rear partition flue is 290°C.

[0041] However, due to the uneven mixing of the two flue gas streams in the front and rear flues, the temperature of the flue gas in some downstream areas is lower than 300°C, resulting in catalyst poisoning (catalyst failure) of the denitrification device, which seriously affects the environmental protection index control requirements of the power plant.

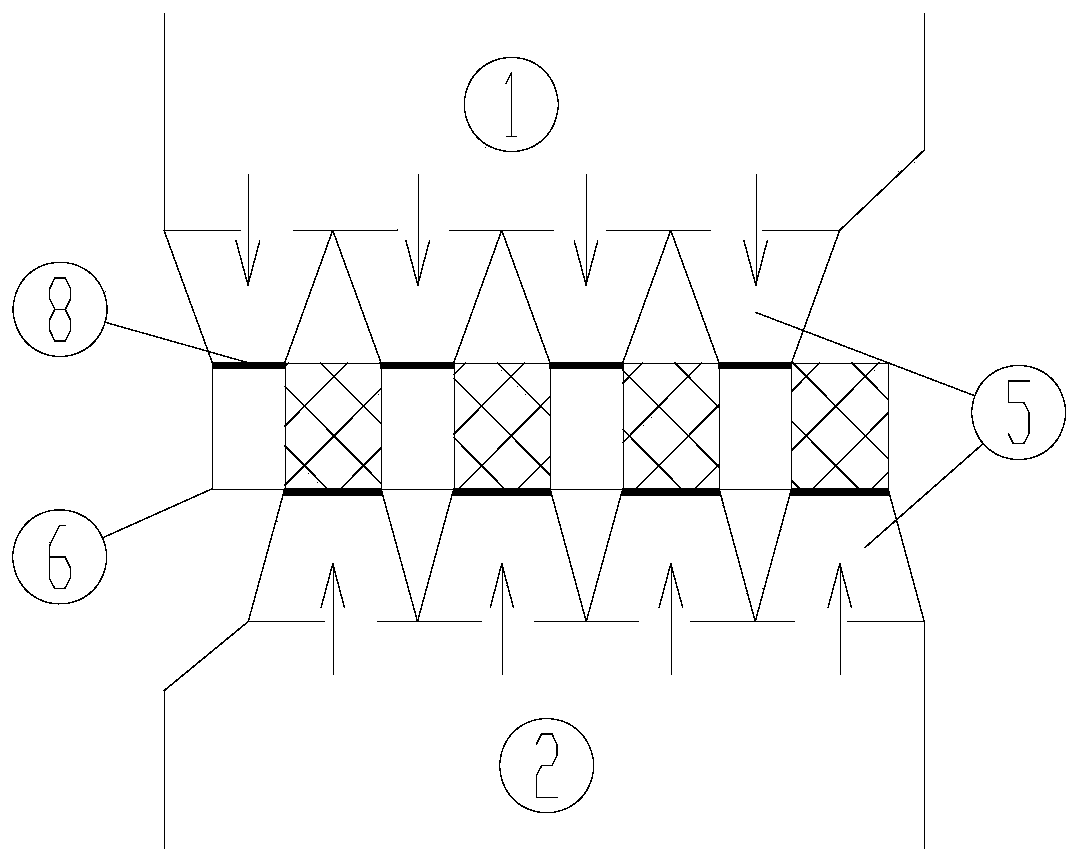

[0042] By adopting the cross-arrangement structure and method of the adjusting baffles of the present invention, the uneven mixing of the separated flue can be effectively solved, and the downstream equipment can be safely operated.

Embodiment 2

[0044] In a power plant, a boiler with double flue baffles at the rear is used for temperature regulation. In the new design, due to site and space constraints, the distance between the combined position of the separated flue at the end and the flue of the downstream equipment is short. According to the conventional structure of the combined flue, it cannot Meet mixing requirements.

[0045] By adopting the structure and method of intersecting arrangement of the regulating baffles of the present invention, the length of the merged flue is compressed through the intersecting and mixing of compartments, and the requirements of the site, space and downstream equipment are met.

[0046] In summary, the present invention arranges an integrated baffle structure capable of adjusting the flow rate at the merging position of each partitioned flue, crosses the flue gas from different partitioned flues into each small compartment along the width direction, and then divides and crosses the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com