Multifunctional extraction tank

A multifunctional extraction tank and gas outlet technology, applied in solvent extraction, solid solvent extraction, chemical instruments and methods, etc., can solve the problems of low extraction efficiency of material and liquid, unbalanced heating of the main tank, foam ingress, etc. The effect of improved extraction efficiency, no material consumption, and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

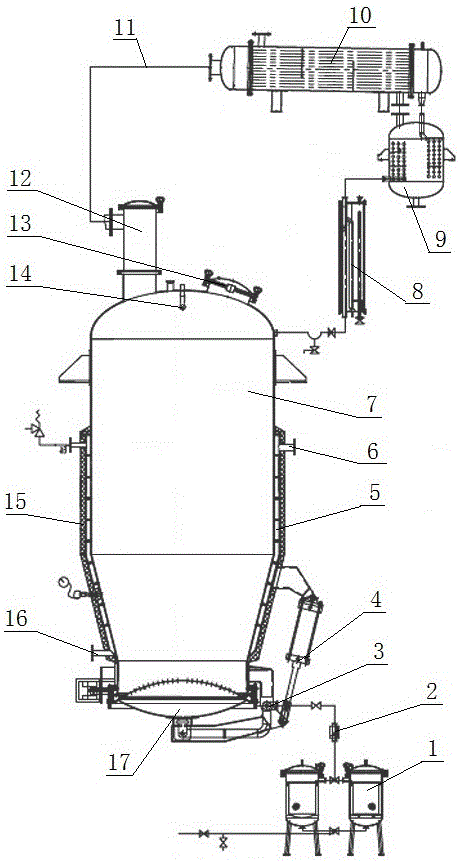

[0012] like figure 1 A multi-functional extraction tank shown includes a main tank 7 with a liquid outlet pipe 3 at the bottom and a gas outlet at the top, and the gas outlet of the main tank 7 is connected to a condenser 10, a cooler 9 and an oil-water separator through pipelines in sequence. Device 8, oil-water separator 8 is equipped with the return pipe that connects main tank 7 top, and demister 12 is housed at the air outlet of main tank 7, and demister 12 is connected with condenser 10 by inlet pipe 11, present embodiment The condenser 10 is a tube-and-tube condenser; the main tank 7 is equipped with a jacket 5, the bottom of the jacket 5 is equipped with a condensate drain pipe 16, and the upper part of the jacket 5 is equipped with two opposite steam inlets. Pipe 6, the outer surface of jacket 5 is covered with insulation layer 15, and the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com