Pressure cooker lid cleaning method and cleaning system

A cleaning system and pressure cooker technology, applied to pressure cookers, cooking utensils, household utensils, etc., can solve the problems of products that are prone to bumps and damage product quality, difficult to adapt to large-scale production efficiency, labor costs and high labor intensity, and achieve cleaning effects Fast and thorough, avoiding adverse effects, the effect of coating quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

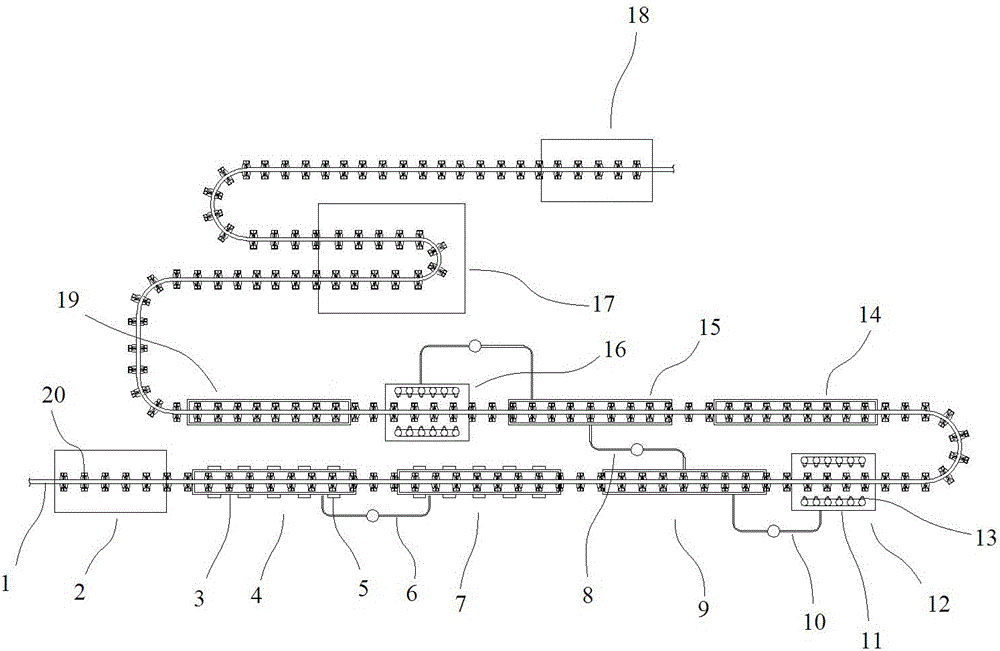

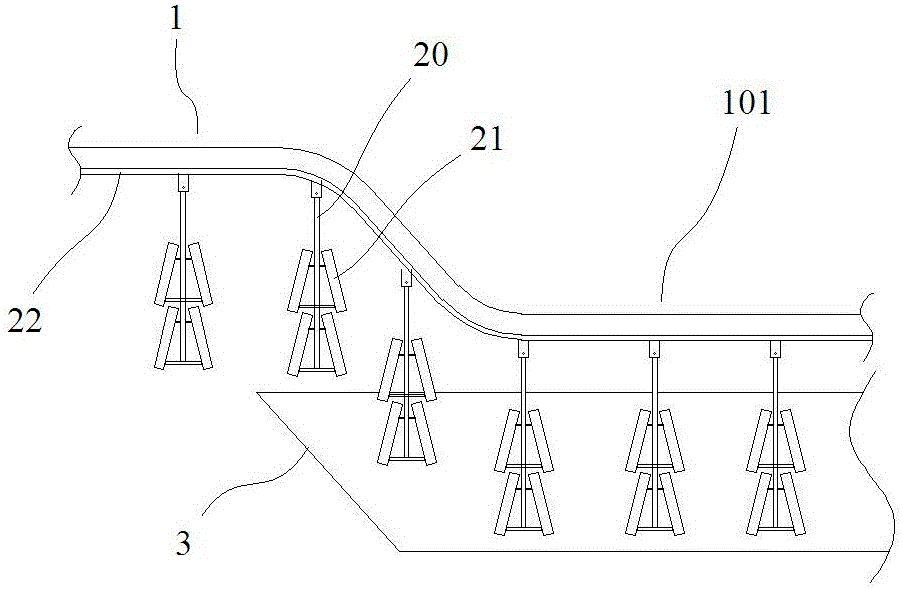

[0026] like figure 1 In the shown embodiment, a kind of pressure cooker lid cleaning method comprises the following steps:

[0027] (a) In an acidic environment with a temperature of 40 ± 5 degrees Celsius, the optimal temperature is controlled at 40 degrees Celsius. At this time, the pH value is 2-3, and the wax-removing water is used as the medium to ultrasonically clean the lid of the pressure cooker during travel. Ultrasonic cleaning time 3-5 minutes. Wax removal water can use three-in-one wax removal water. In addition to removing oil and wax, it can also remove the surface oxide layer and further improve the adhesion of the surface protective layer in the subsequent coating process. The pressure cooker lid is subjected to multiple ultrasonic cleanings in the traveling direction, and the frequency of the ultrasonic wave increases gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com