Preparation method of peony seed oil powder oil containing active peptides

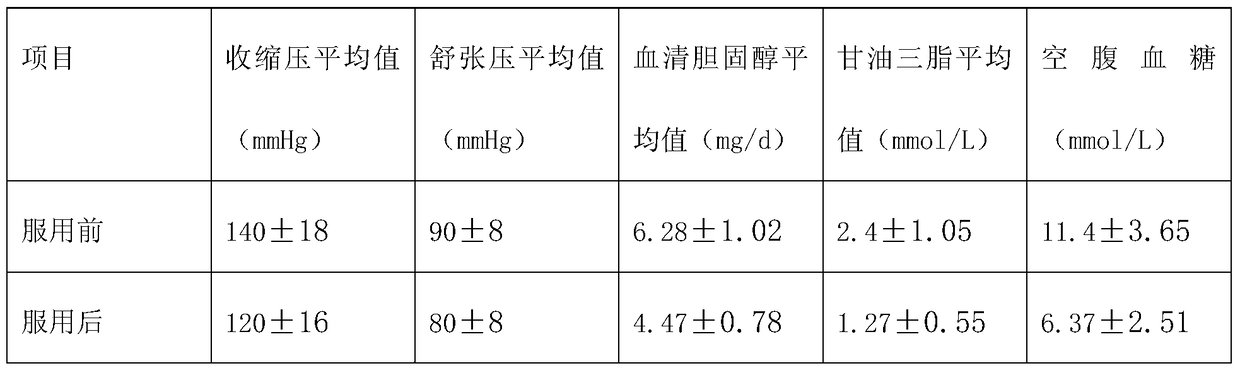

A technology of peony seed oil and powdered oil, applied in the fields of edible oil/fat, food science, application, etc., to achieve the effects of high nutritional value, memory improvement, and prevention of three high diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039](1) Dissolve the wall material and active peptide with distilled water at 55°C, then stir while heating, and heat to about 65°C. After the dissolved matter is uniformly dispersed, a solution A is obtained; the weight ratio of the dissolved matter to water is 1:3 , the active peptide is a mixture of peanut polypeptide and corn polypeptide, the weight ratio of peanut polypeptide and corn polypeptide is 1:2, the molecular weight of peanut polypeptide is 200-1000Da, and the molecular weight of corn polypeptide is 200-800Da;

[0040] (2) Add food functional factors and emulsifiers to peony seed oil, mix at 55°C, stir evenly to obtain an emulsion; (3) shear and emulsify the emulsion obtained in step (2), shear The rotating speed is 15000r / min, and the time is 10min to obtain an emulsified solution;

[0041] (4) Add the A solution obtained in step (1) to the emulsified solution after step (3) shearing, high-pressure homogenization, and the pressure of high-pressure homogenizati...

Embodiment 2

[0060] (1) Dissolve the wall material and active peptide with distilled water at 45°C, then stir while heating, and heat to 65°C. After the dissolved matter is uniformly dispersed, a solution A is obtained; the weight ratio of the dissolved matter to water is 1:3, The active peptide is a mixture of peanut polypeptide and corn polypeptide, the weight ratio of peanut polypeptide and corn polypeptide is 1:3, the molecular weight of peanut polypeptide is 200-1000Da, and the molecular weight of corn polypeptide is 200-800Da;

[0061] (2) Add food functional factors and emulsifiers to peony seed oil, mix at 50°C, stir evenly to obtain an emulsion; (3) shear and emulsify the emulsion obtained in step (2), shear The rotating speed is 10000r / min, and the time is 8min to obtain an emulsified solution;

[0062] (4) Add the A solution obtained in step (1) to the emulsified solution after step (3) shearing, high-pressure homogenization, and the pressure of high-pressure homogenization trea...

Embodiment 3

[0069] (1) Dissolve the wall material and active peptide with distilled water at 60°C, then stir while heating, and heat to 75°C. After the dissolved matter is uniformly dispersed, a solution A is obtained; the weight ratio of the dissolved matter to water is 1:3, The active peptide is a mixture of peanut polypeptide and corn polypeptide, the weight ratio of peanut polypeptide and corn polypeptide is 2:3, the molecular weight of peanut polypeptide is 200-1000Da, and the molecular weight of corn polypeptide is 200-800Da;

[0070] (2) Add food functional factors and emulsifiers to peony seed oil, mix at 60°C, stir evenly to obtain an emulsion; (3) shear and emulsify the emulsion obtained in step (2), shear The rotating speed is 17000r / min, and the time is 12min to obtain an emulsified solution;

[0071] (4) Add the A solution obtained in step (1) to the emulsified solution after step (3) shearing, high-pressure homogenization, and the pressure of high-pressure homogenization tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com